Instrument for detecting density of numeral textile fabric

A fabric density and detector technology, applied in textile testing, instruments, measuring devices, etc., can solve the problems of difficulty in determining the actual density of fabrics, inability to store, transmit, and difficult for multiple people to compare, and achieve rapid and accurate determination of fabric density, Avoid observing differences and improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

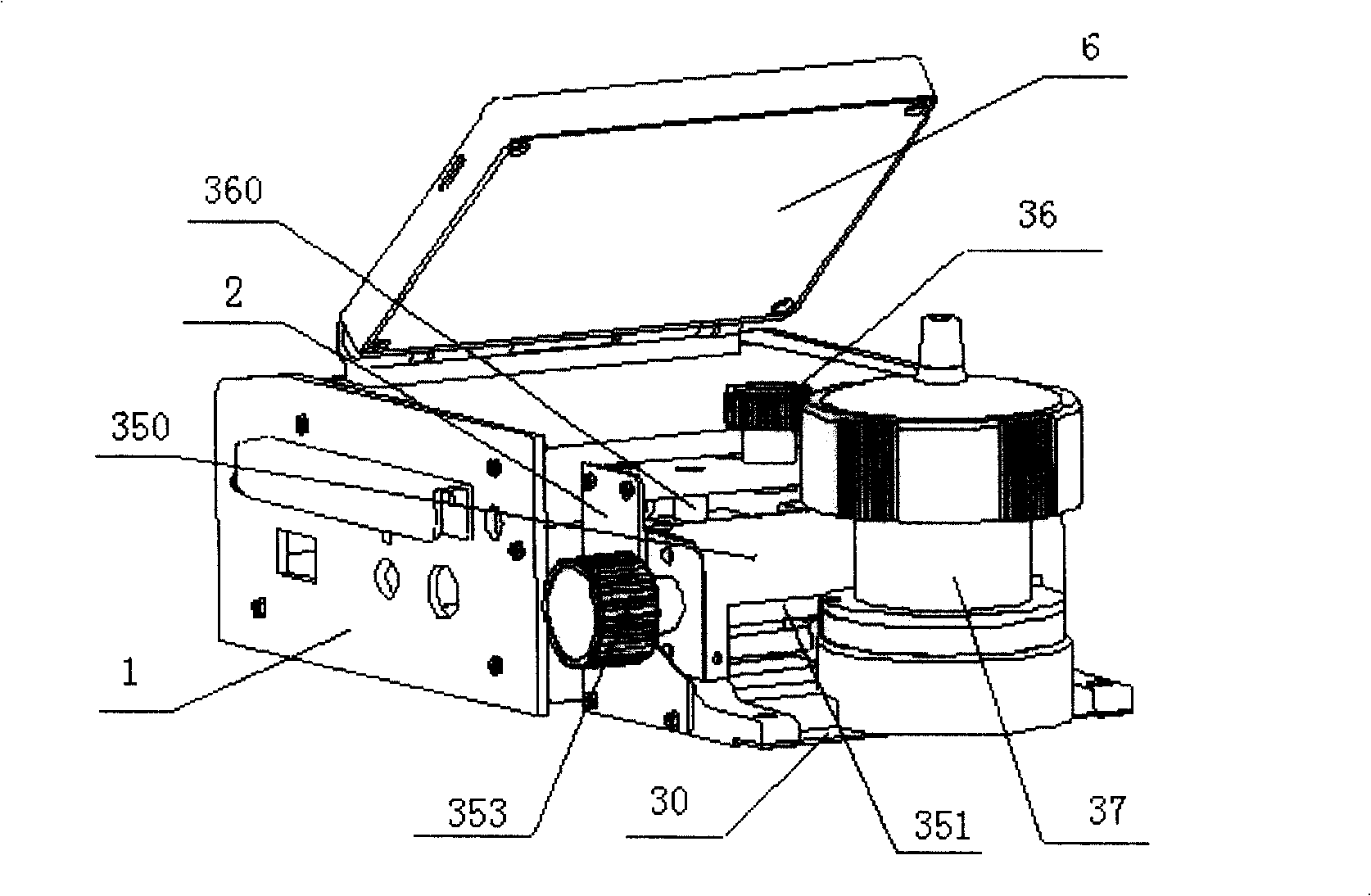

[0022] see Figure 2 to Figure 4 , a digital fabric density detector of the present invention includes a host 1, a fabric magnifying component, a CCD photocoupler 5, an image conversion circuit (not shown) and a liquid crystal display 6. Wherein, the front end of the host 1 is provided with a bracket 2; the side wall of the host 1 is provided with an AV output interface 11, a charging socket 12 and a power switch 13, and the AV output interface 11 is used to change the image signal into a video signal, and can be connected with The computer of AV card or TV; The upper face of the bracket 2 has a perforation 20 .

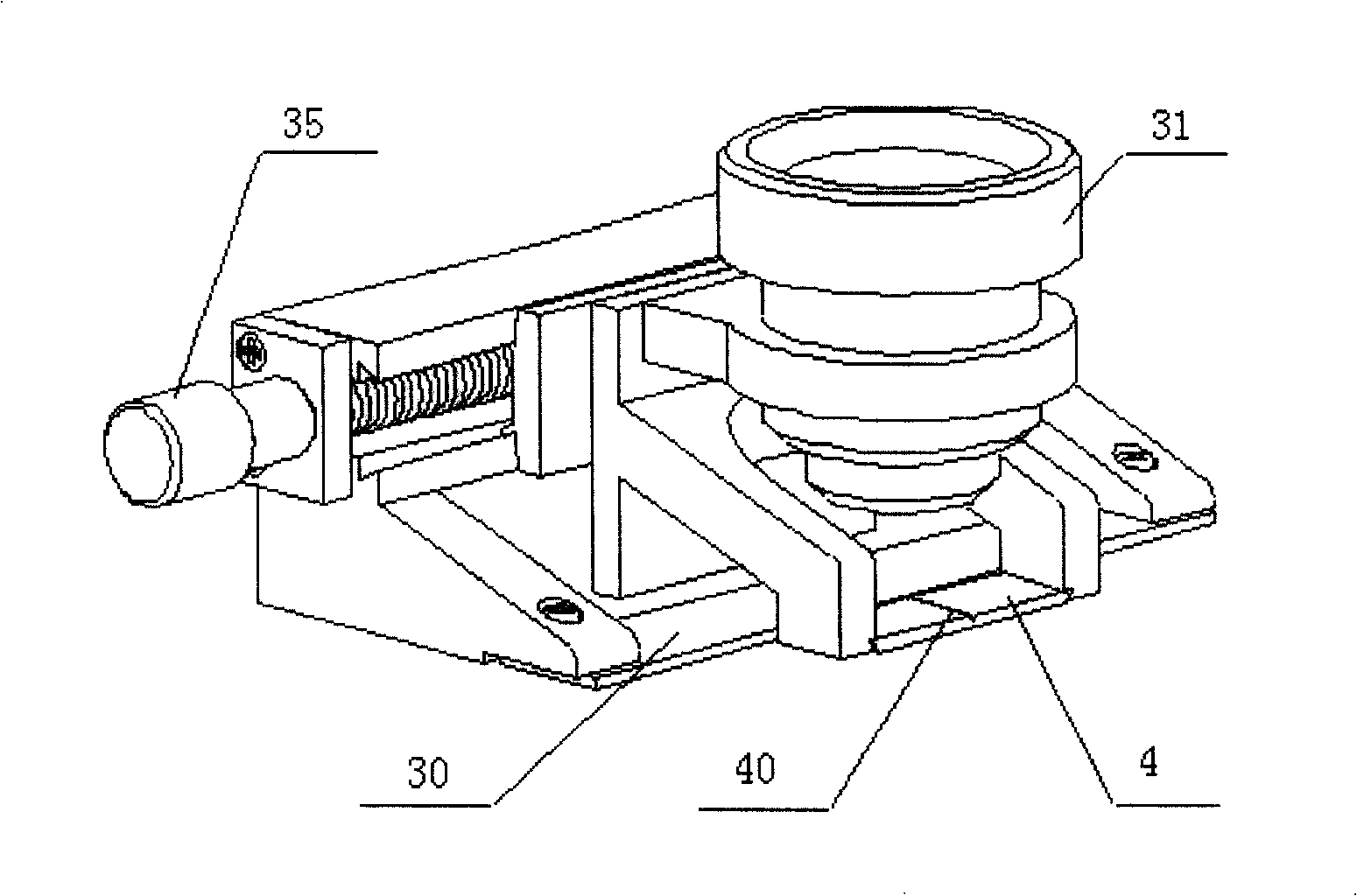

[0023] The fabric magnifying part comprises a fabric measuring device, an optical system with a magnifying lens 31 and a camera lens 32, a sunshade 33, an illuminating lamp 34, a transverse transmission mechanism 35 and a focusing mechanism 36. The fabric measuring device contains a ruler 30 with a size scale that can be intercepted by a magnifying glass 31. The ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com