High-strength high-ductility Mg-Al-Mn die-casting magnesium alloy containing lanthanum-cerium mixed rear earth

A mixed rare earth, high-strength and high-toughness technology, applied in the field of metal materials, can solve the problems of poor corrosion resistance and low strength of AM60 die-casting magnesium alloy, and achieve improved corrosion resistance, good performance of die-casting process, and simple and easy production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

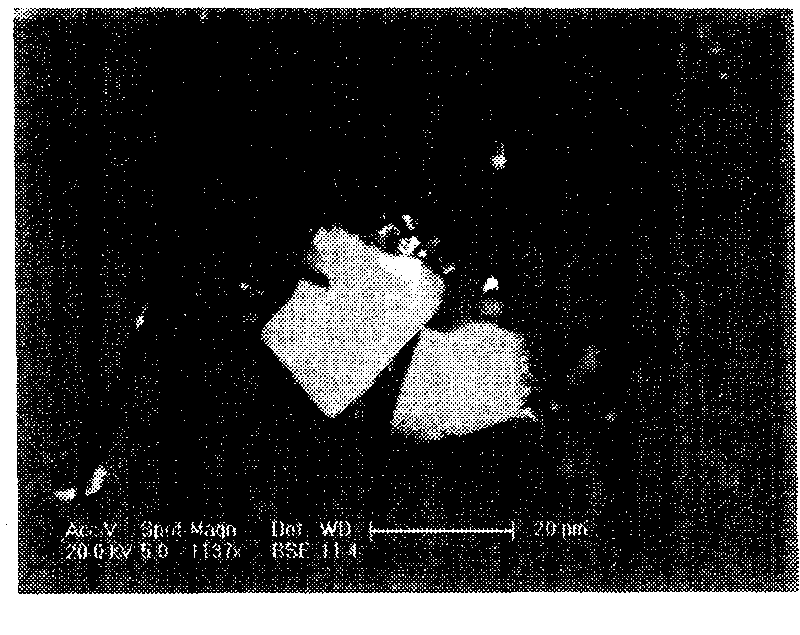

Image

Examples

Embodiment 1

[0018] Embodiment 1AM60+CeLa (Ce=0.2, La=0.3) die-casting magnesium alloy

[0019] The preparation method of AM60+CeLa (Ce=0.2, La=0.3) die-casting magnesium alloy is as follows:

[0020] 1. Preparation of magnesium-lanthanum-cerium master alloy: according to the mass ratio of 80% magnesium and 20% mixed rare earth raw materials, the magnesium ingot and mixed rare earth raw materials are put into a cast iron or graphite crucible, heated and melted, and the temperature is raised to 780°C. Stir evenly and cast into a magnesium-lanthanum-cerium master alloy ingot. SF is introduced into the smelting process 6 :CO 2 Protective gas with a volume ratio of 1:200. The mixed rare earth raw material used for preparing the master alloy is the lanthanum-cerium mixed rare earth after separating Pr and Nd from the cerium-rich mixed rare earth.

[0021] 2. Preparation of high-strength and high-toughness Mg-Al-Mn die-casting magnesium alloy: according to the weight ratio of 97.5% for AM60 ...

example 2

[0025] Example 2 AM60+CeLa (Ce=0.6, La=0.4) die-casting magnesium alloy

[0026] The AM60+CeLa (Ce=0.6, La=0.4) die-casting magnesium alloy is formulated according to the following mass percentages: 95% for the AM60 magnesium alloy, and 5% for the magnesium-lanthanum-cerium master alloy. Its preparation method is as embodiment 1.

[0027] The chemical composition of the obtained alloy is by mass percentage:

[0028] Al

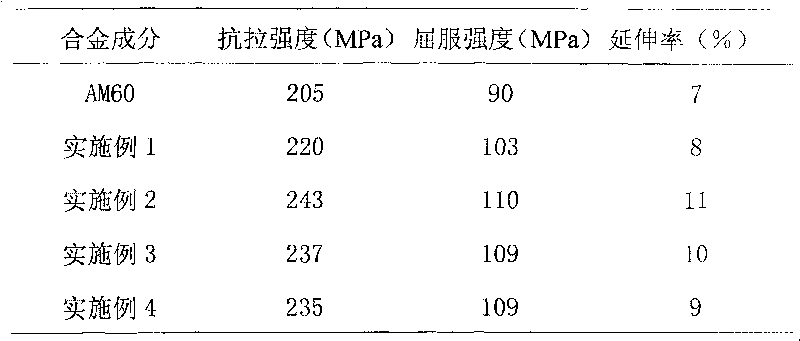

[0029] The high-strength and high-toughness Mg-Al-Mn die-casting magnesium alloy containing cerium-lanthanum mixed rare earth prepared according to the aforementioned process steps, the properties of the alloy are shown in Table 1 and Table 2.

example 3

[0030] Example 3 AM60+CeLa (Ce=0.6, La=0.9) die-casting magnesium alloy

[0031] The AM60+CeLa (Ce=0.6, La=0.9) die-casting magnesium alloy is formulated according to the following mass percentages: 92.5% for the AM60 magnesium alloy and 7.5% for the magnesium-lanthanum-cerium master alloy. Its preparation method is as embodiment 1.

[0032] The chemical composition of the obtained alloy is by mass percentage:

[0033] Al

[0034] The high-strength and high-toughness Mg-Al-Mn die-casting magnesium alloy containing cerium-lanthanum mixed rare earth prepared according to the aforementioned process steps, the properties of the alloy are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com