Method for producing phosphobacteria bio-fertilizer by using urban sludge

A technology of municipal sludge and biological fertilizer, applied in the direction of microorganism-based methods, sewage/sludge fertilizer, biochemical equipment and methods, etc., can solve the problems of low spore formation rate, high price, and high cost, and reduce production costs , promote popularization and application, and reduce disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

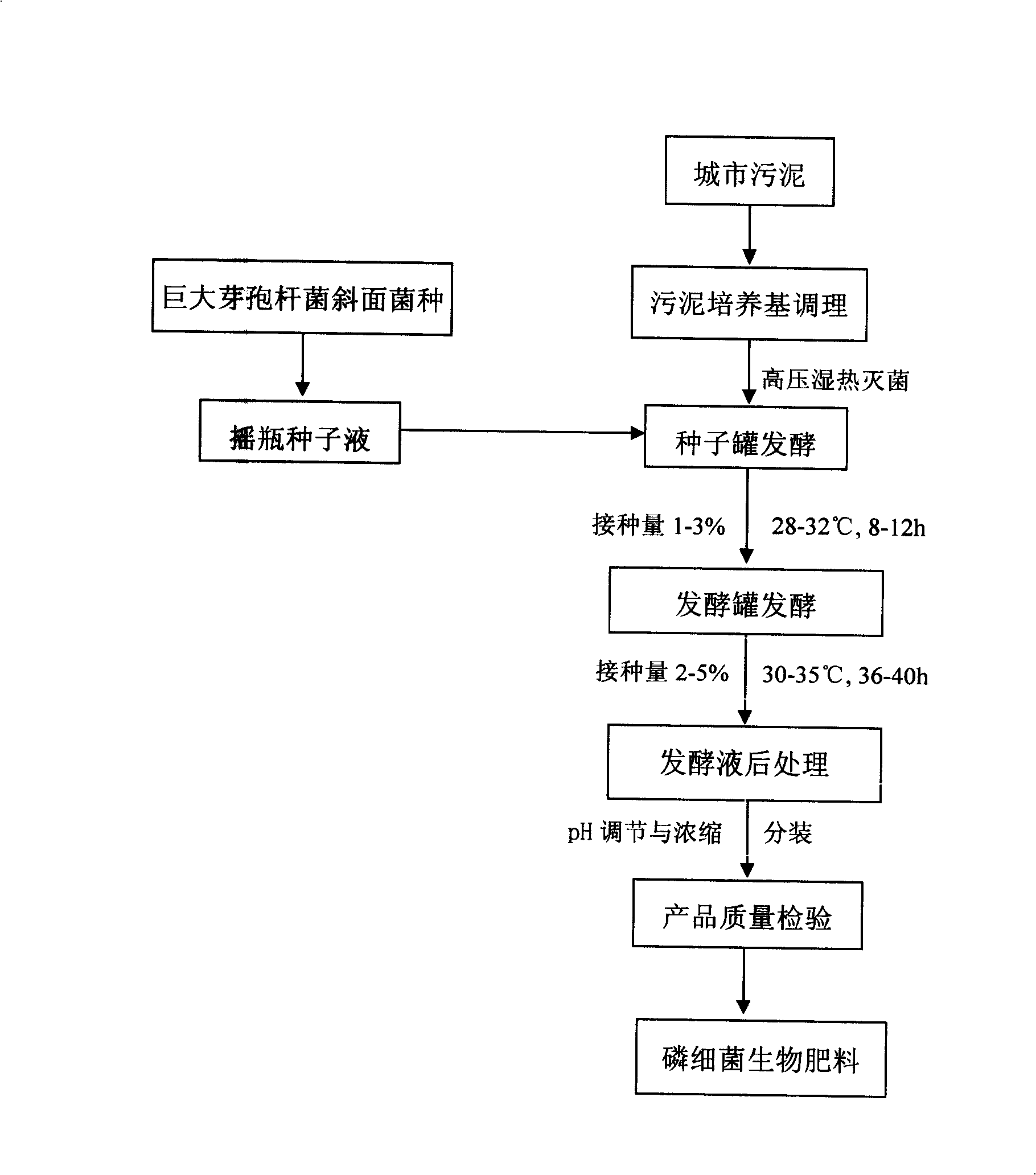

Method used

Image

Examples

Embodiment 1

[0036] (1) Municipal sludge samples

[0037] Take the thickened sludge from a sewage treatment plant in Shanghai. The basic properties of the sludge are shown in Table 2.

[0038] Table 2 Basic properties of the tested sludge

[0039] pH

Solid content

(%)

total carbon

(%)

(%)

(%)

mg / kg

HG

mg / kg

lead

mg / kg

chrome

mg / kg

mg / kg

7.39

3.30

30.5

2.32

1.17

1.2

0.7

63

115

12

[0040] (2) Sludge conditioning

[0041]Use tap water to adjust the solid content of the sludge to 3.0%, add 2.0g / L of antifoaming agent containing silicon-containing foam enemy XPJ960, adjust the pH to 6.9 with phosphoric acid, and test the pressure of 15 pounds and the temperature of 121°C in the seed tank and fermentation tank respectively. Sterilize for 60 minutes, cool to 35°C for later use...

Embodiment 2

[0058] (1) Municipal sludge samples

[0059] The properties of municipal sludge samples are the same as in Table 1.

[0060] (2) Sludge conditioning

[0061] Use tap water to adjust the solid content of the sludge to 2.0%, add 1.0g / L of antifoaming agent polyether antifoaming agent GPE, adjust the pH to 6.8 with phosphoric acid, and pass 15 pounds of pressure and 121°C in the seed tank and fermentation tank respectively. Sterilize for 60 minutes, cool to 35°C for later use, and the pH after sterilization is about 7.0.

[0062] (3) Shake flask culture

[0063] The strain was changed from Bacillus megaterium ACCC10010 to ACCC10099 strain, and the rest were the same as in Example 1.

[0064] (4) Seed tank fermentation

[0065] Inoculate 3.0% of the above-mentioned shake flask bacterial liquid, and ferment and cultivate. The culture conditions are: tank temperature 35° C., tank pressure 0.03 MPa, ventilation rate 1:1.0 (V / V / min), stirring speed 240 rpm, and fermentation time ...

Embodiment 3

[0074] (1) Municipal sludge samples

[0075] Take the thickened sludge from a sewage treatment plant in Guangzhou, Guangdong Province. The basic properties of the sludge are shown in Table 6.

[0076] Table 6 Basic properties of tested sludge

[0077] pH

[0078] (2) Sludge conditioning

[0079] Use tap water to adjust the solid content of municipal sludge to 4.0%, add 3g / L of antifoaming agent containing silicon foam enemy XPJ960, adjust the pH to 6.8 with sodium hydroxide, and pass 15 pounds of pressure and 121 in the seed tank and fermentation tank respectively. Sterilize at ℃ for 60 minutes, cool to 32℃ for later use, and the pH after sterilization is about 7.2.

[0080] (3) Shake flask culture

[0081] Pick a loop from the slant of Bacillus megaterium ACCC10099 and inoculate it into a triangular flask containing beef extract peptone liquid medium for shaking flask culture. The culture conditions are: temperature 32°C, rotation speed 200 rpm, 500 mL Erlenmeye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com