Chalcohalide glasses ceramic having broadband optical window and preparation method thereof

A technology of optical window and sulfur-halogen glass, which is applied in the field of optical window glass-ceramic materials, can solve the problems of poor mechanical properties and inability to cover the 0.4-0.6 band, and achieve the effects of improving mechanical properties and simplifying complex photoelectric detection systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]A sulfur-halogen glass ceramic with a broadband optical window, its composition is shown in Table 1, 55GeS 2 ·15In 2 S 3 · 30CsCl, 55, 15, 30 are the mole percentage of each compound.

[0035] The specific preparation method is as follows:

[0036] 1). Select raw materials: according to 55GeS 2 ·15In 2 S 3 30CsCl, 55, 15, and 30 are the molar percentages of each compound, select elemental Ge, In, S and compound CsCl raw materials, the purity of elemental Ge, In, S, and CsCl are respectively ≥ 99.999% (mass), and set aside;

[0037] 2). In an environment full of inert gas, mix Ge, In, S and compound CsCl raw materials, grind and mix to make batches, put them in a container and vacuumize, the vacuum degree is 10 -4 ~10 -6 Pa, then seal the container and place it in a heating device;

[0038] 3). Preparation of the basic glass: heat the container containing the batch material in step 2), first slowly raise the temperature to 595°C-605°C at a rate of less than 1°C / mi...

Embodiment 2

[0042] A sulfur-halogen glass-ceramic with a broadband optical window, its composition is shown in Table 1.

[0043] The specific preparation method is as follows:

[0044] 1). Carry out according to Embodiment 1 of 1);

[0045] 2). Carry out according to embodiment 1 of 2).

[0046] 3). Carry out according to embodiment 1 of 3).

[0047] 4). Put the basic glass sheet prepared in step 3) into a crystallization furnace, raise the temperature to 270°C, keep the temperature for 6 hours, and carry out nucleation; then increase the temperature to 300°C, keep the temperature for 1 hour, and complete the crystallization; Lower the temperature to 240-280°C, keep the temperature constant for 0.5-3 hours, eliminate stress, cool down with the furnace, release from the furnace, and polish to get the finished product.

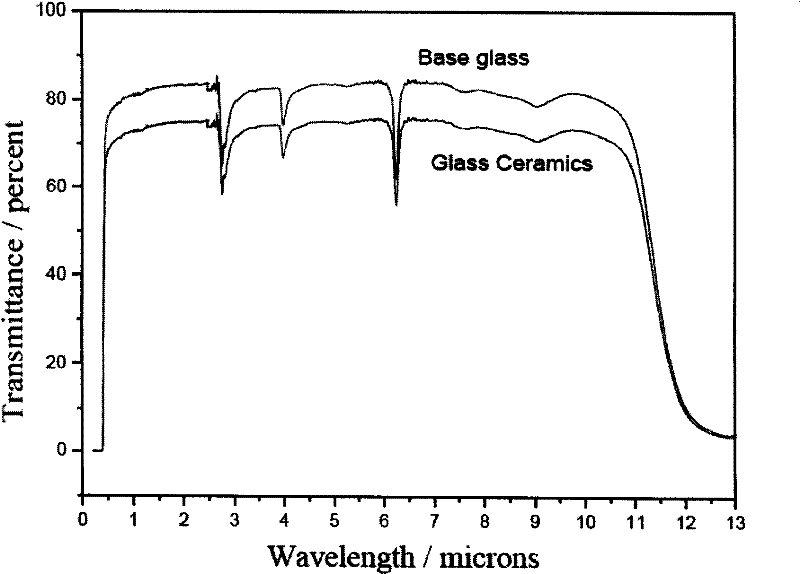

[0048] The optical transmission window of the prepared sulfur-halide glass-ceramic is 0.4-11.5 μm, and the anti-crack expansion ability is 6 times that of the existing s...

Embodiment 3

[0050] A sulfur-halogen glass-ceramic with a broadband optical window, its composition is shown in Table 1.

[0051] The specific preparation method is as follows:

[0052] 1). Carry out according to Embodiment 1 of 1);

[0053] 2). Carry out according to embodiment 1 of 2).

[0054] 3). Carry out according to embodiment 1 of 3).

[0055] 4). Put the basic glass sheet prepared in step 3) into a crystallization furnace, raise the temperature to 290°C, keep the temperature for 16 hours, and carry out nucleation; then increase the temperature to 330°C, keep the temperature for 1 hour, and complete the crystallization; Lower the temperature to 240-280°C, keep the temperature constant for 0.5-3 hours, eliminate the stress, cool down with the furnace, release from the furnace, and polish to get the finished product.

[0056] The optical transmission window of the prepared sulfur-halide glass-ceramic is 0.4-11.5 μm, and the anti-crack expansion ability is four times that of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com