Wafer-level burn-in method and wafer-level burn-in apparatus

An aging device, wafer-level technology, applied in measurement devices, instruments, measurement electronics, etc., can solve problems such as difficulty in ensuring wafer temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

[0039] (Embodiment 1)

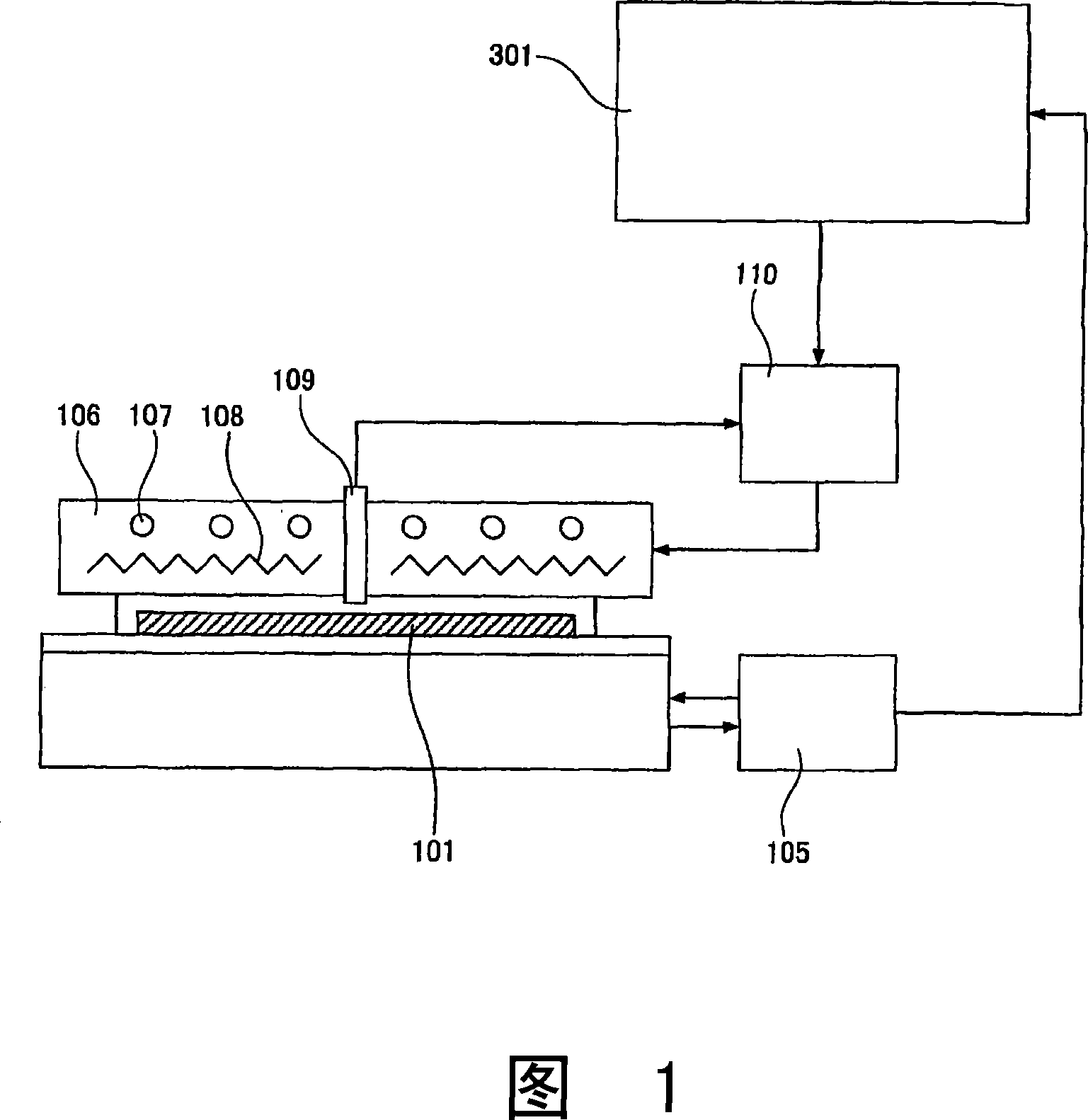

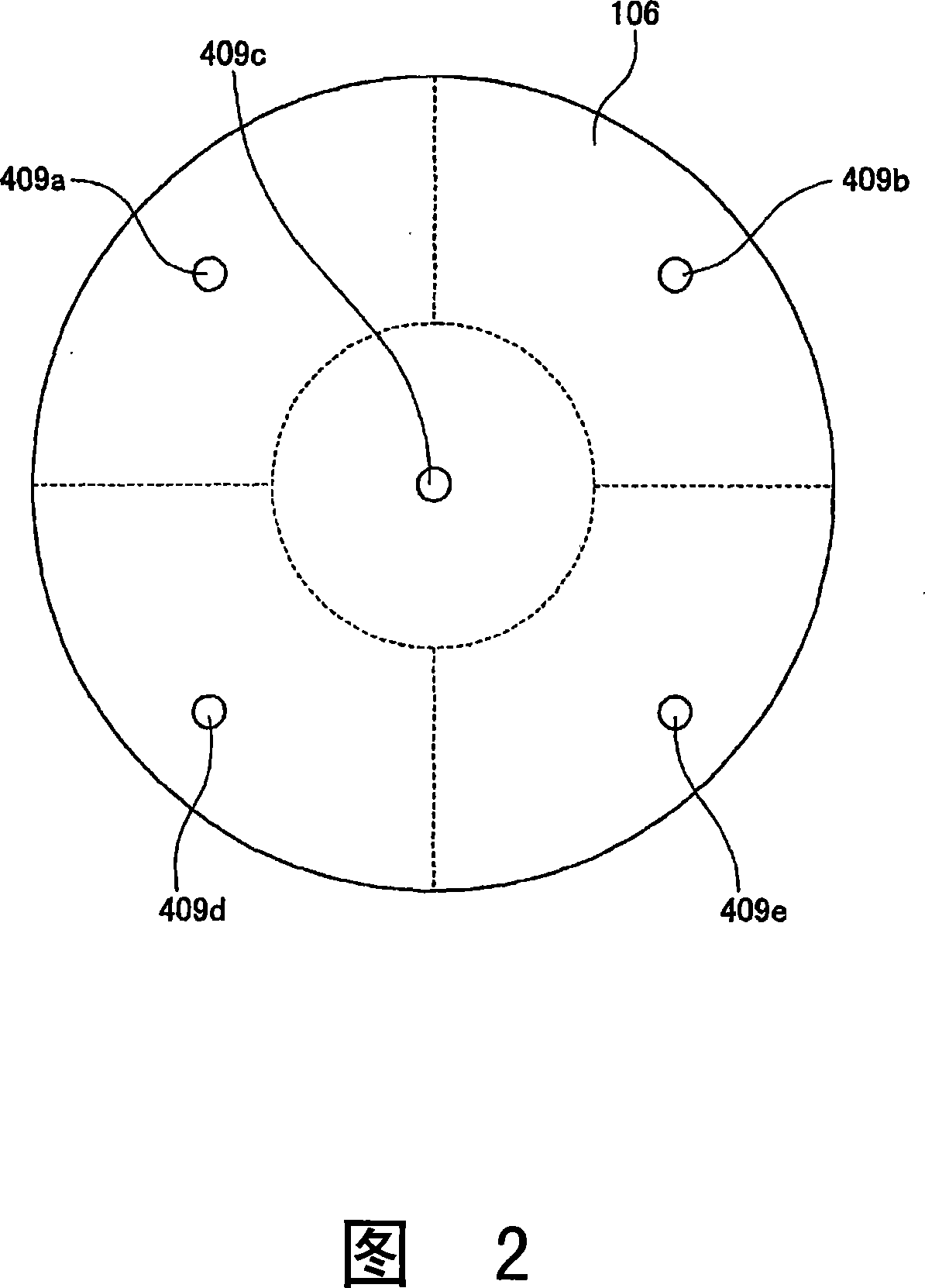

[0040] FIG. 1 is a schematic diagram of a wafer-level burn-in apparatus in Embodiment 1 of the present invention. The first embodiment shown in FIG. 1 is a configuration obtained by adding a temperature correction value calculating device 301 to the device configuration shown in FIG. 4 .

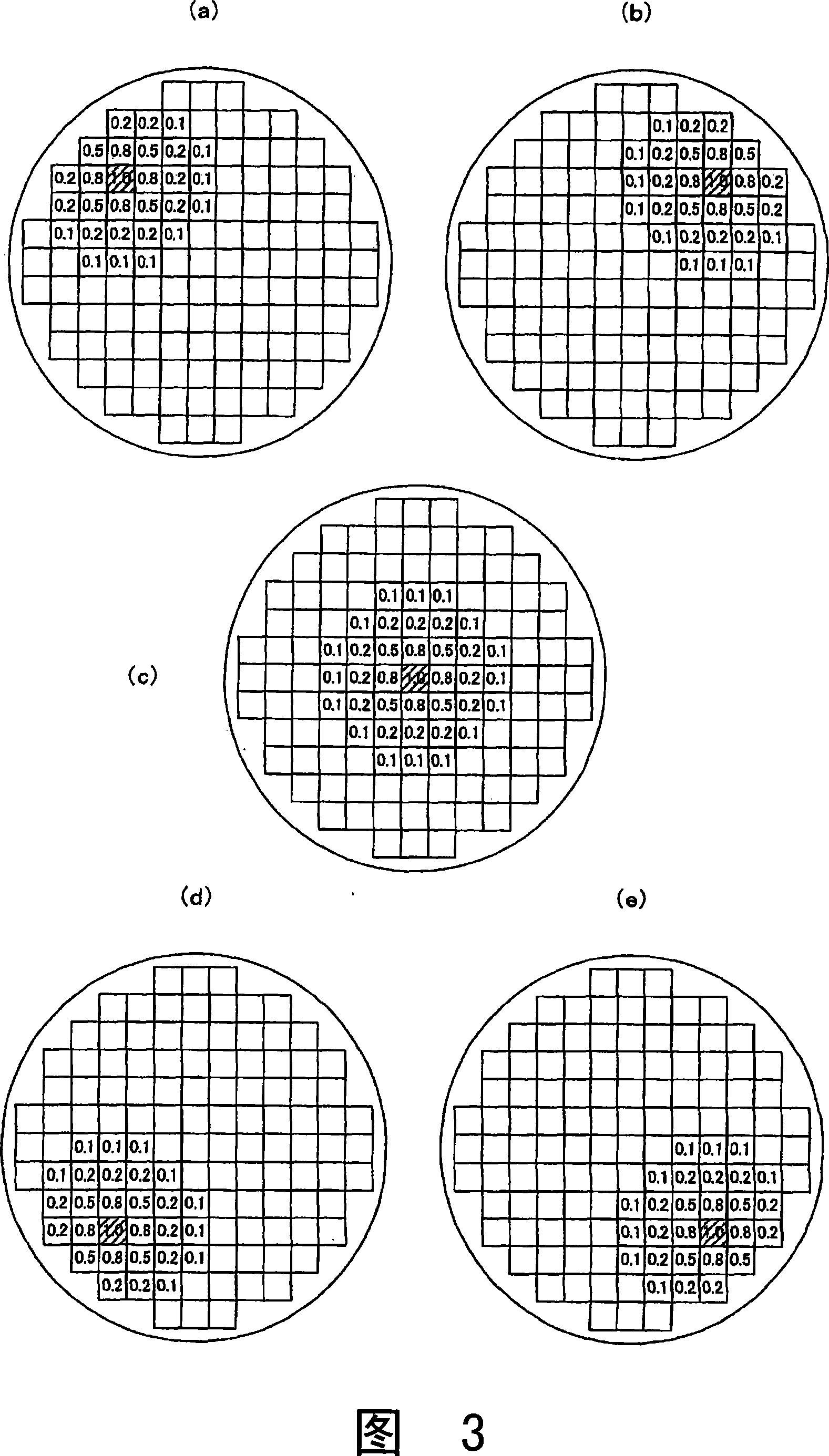

[0041] In the wafer-level burn-in according to the first embodiment using such a structure, experiments are performed in advance to test the wafer 101 caused by heat generated by power consumption on the device when an electrical load is applied to the device formed on the wafer 101. The difference between the actual temperature of 101 and the temperature measured by the temperature sensor 109 is calculated as a function of the amount of heat generated per unit area on the wafer 101 , that is, the heat generation density. In this Embodiment 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com