Printed circuit board

A technology for wiring circuit boards and signal lines, which is applied to printed circuits, printed circuits, circuit devices, etc., can solve the problems of thinning circuit boards that are difficult to wire, and achieve the effect of preventing high-frequency noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] Hereinafter, examples and comparative examples of the present invention will be described.

no. 1 example

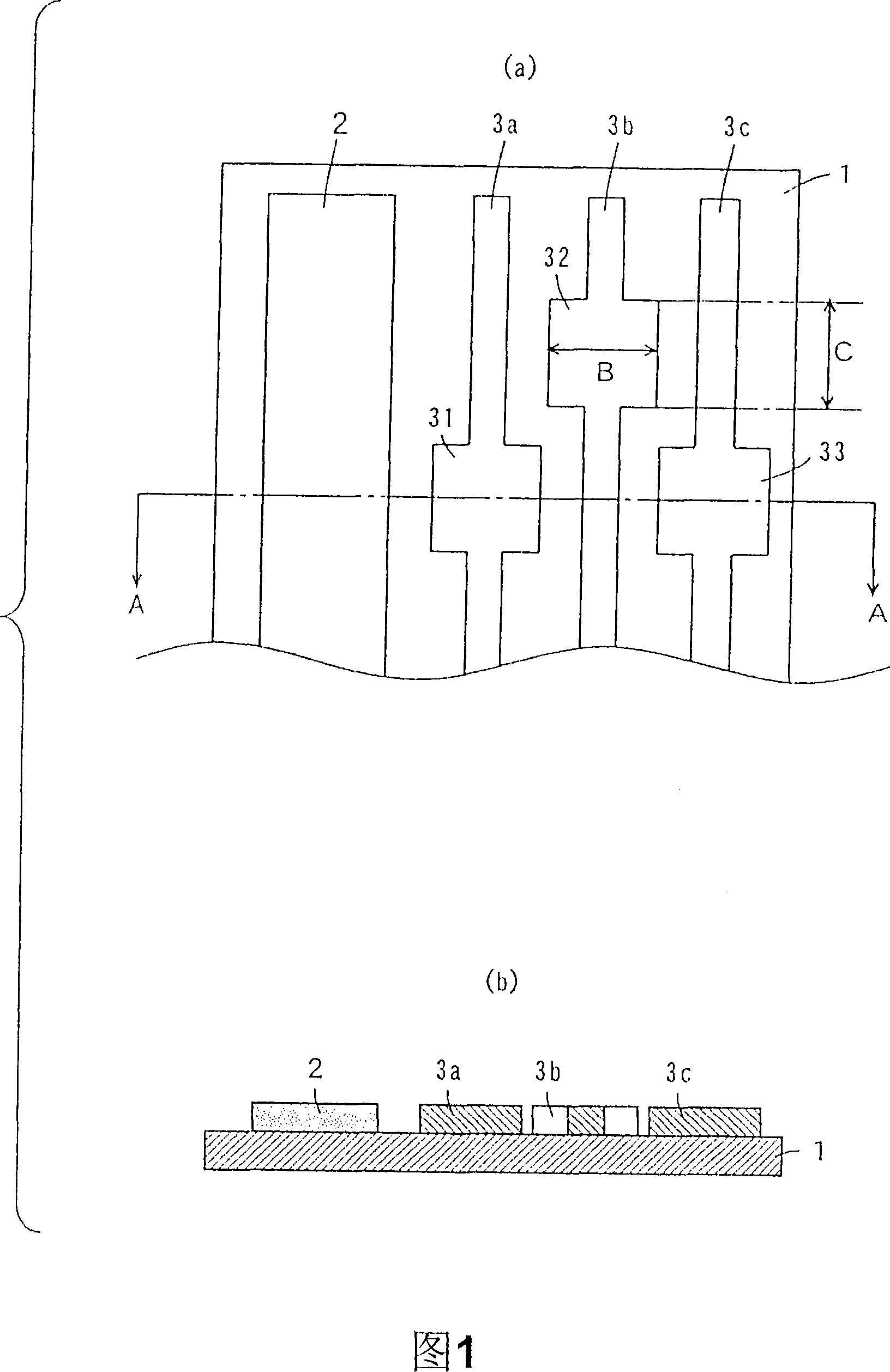

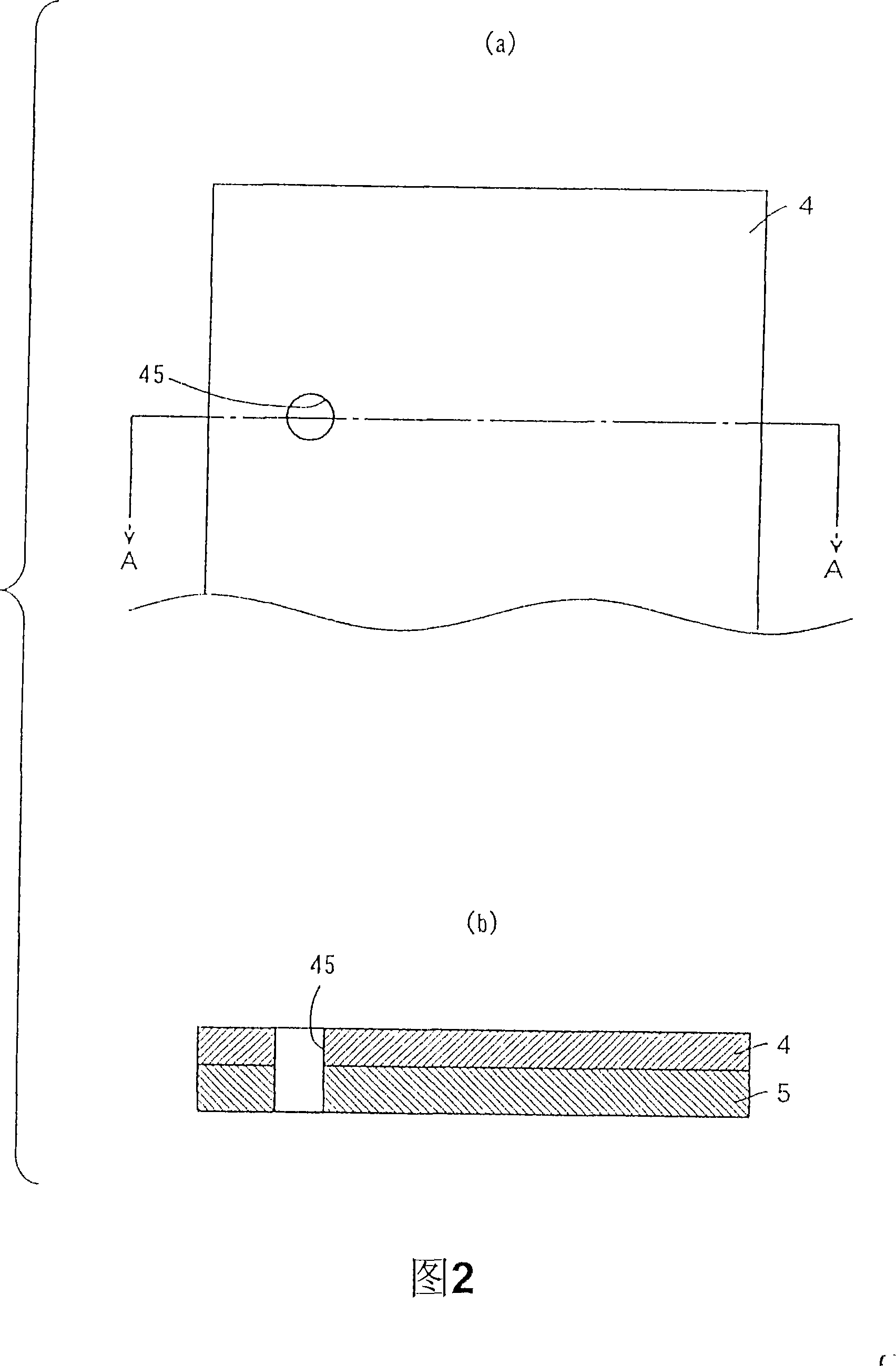

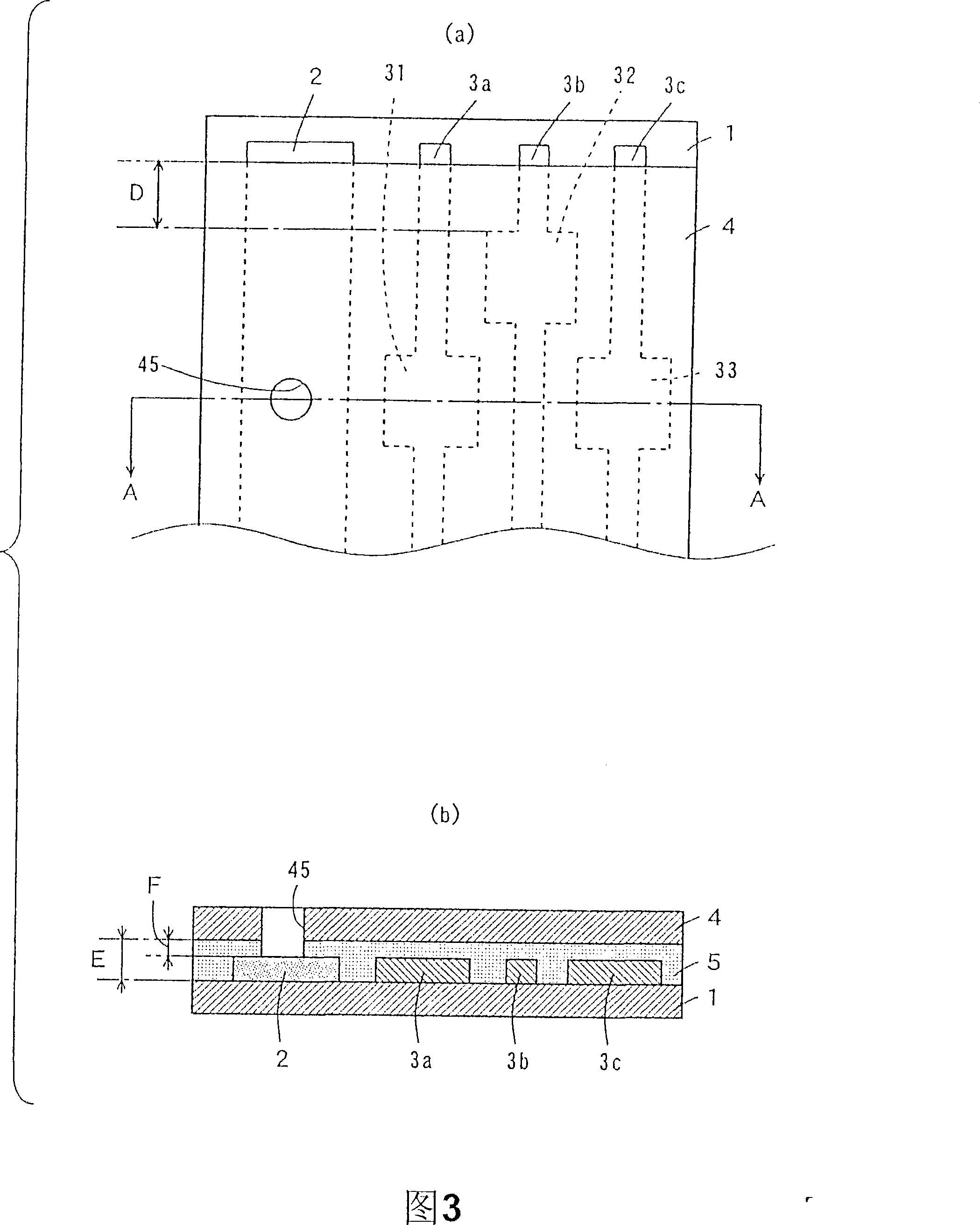

[0065] Fig. 7 is a top view showing the printed circuit board according to the first embodiment of the present invention. The printed circuit board 102 of FIG. 7 differs from the printed circuit board 101 of FIG. 6 in the following points. As shown in FIG. 7 , on printed circuit board 102 , wide portion 31 and wide portion 33 are arranged at positions closer to one end of first insulating cover layer 4 than wide portion 32 . In addition, the A-A line sectional view of the printed circuit board 102 is the same as that of FIG. 6( b ).

[0066] As the bottom insulating layer 1 of the printed circuit board 102, a polyimide resin having a thickness of 25 μm was used. The first to third signal lines 3 a to 3 c have a width of 0.2 mm and a thickness of 18 μm. The width B of the wide portions 31 to 33 is 3 mm, and the length C is 2 mm. The distance D between the wide portion 31 and the wide portion 33 and one end of the first insulating cover layer 4 was 5 mm.

[0067] In addition...

no. 2 example

[0070] The printed circuit board of the second embodiment differs from the printed circuit board 102 of FIG. 7 in the following points. In the printed circuit board of the second embodiment, the width B of the wide portions 31 to 33 is 1 mm, and the length C is 2 mm.

[0071] In the case of transmitting a high-frequency digital signal of 100 MHz using this printed circuit board, harmonics of 1280 MHz or higher can be removed, and high-frequency noise of 1280 MHz or higher does not occur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com