Hydropower floating quick vertical ship lift

A vertical ship lift and floating technology, applied in the field of ship lifts, can solve the problems of large operating water consumption and safety devices that cannot cope with water leakage in the ship's chamber, achieving small maintenance workload, fast lifting speed, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

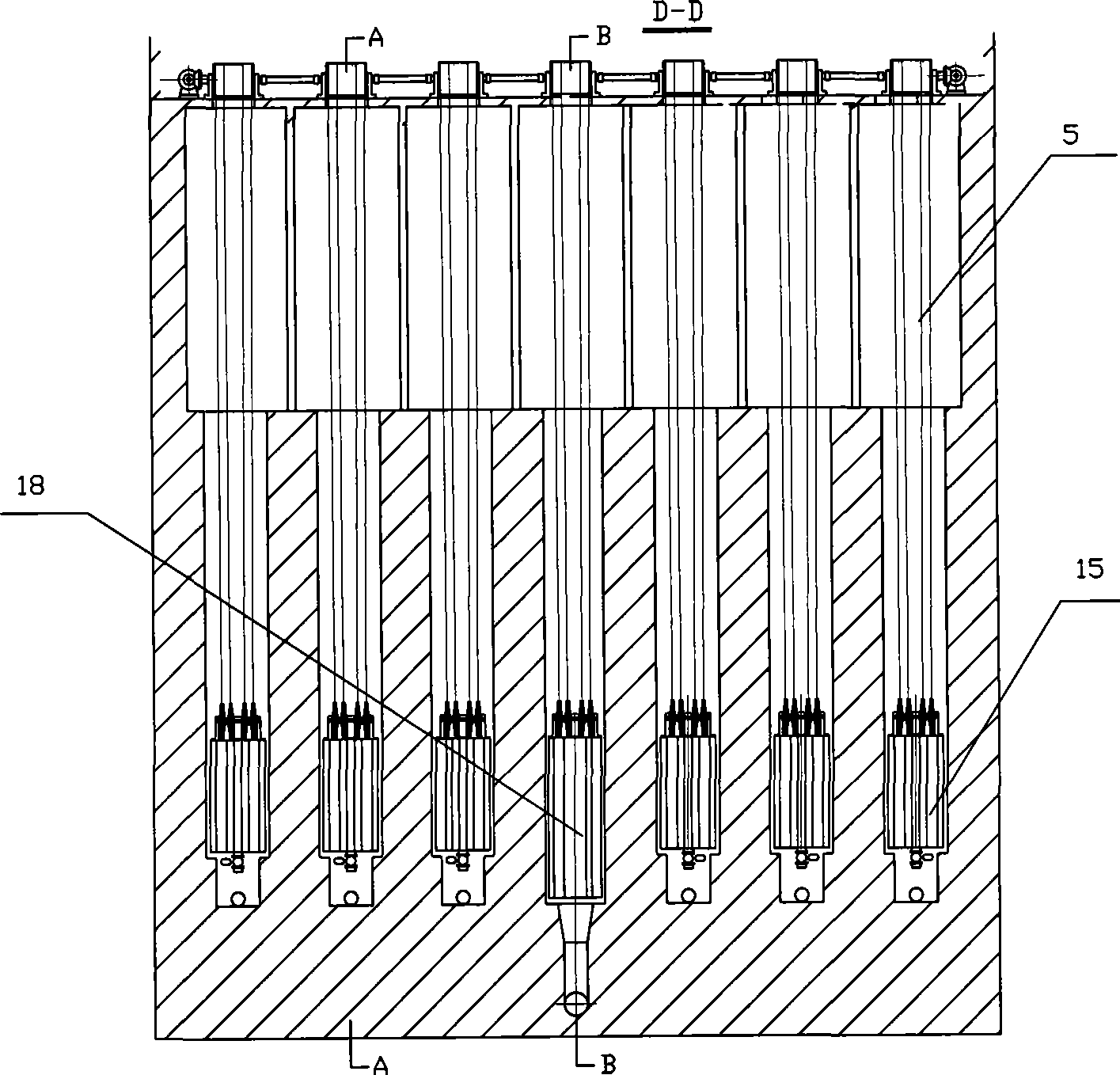

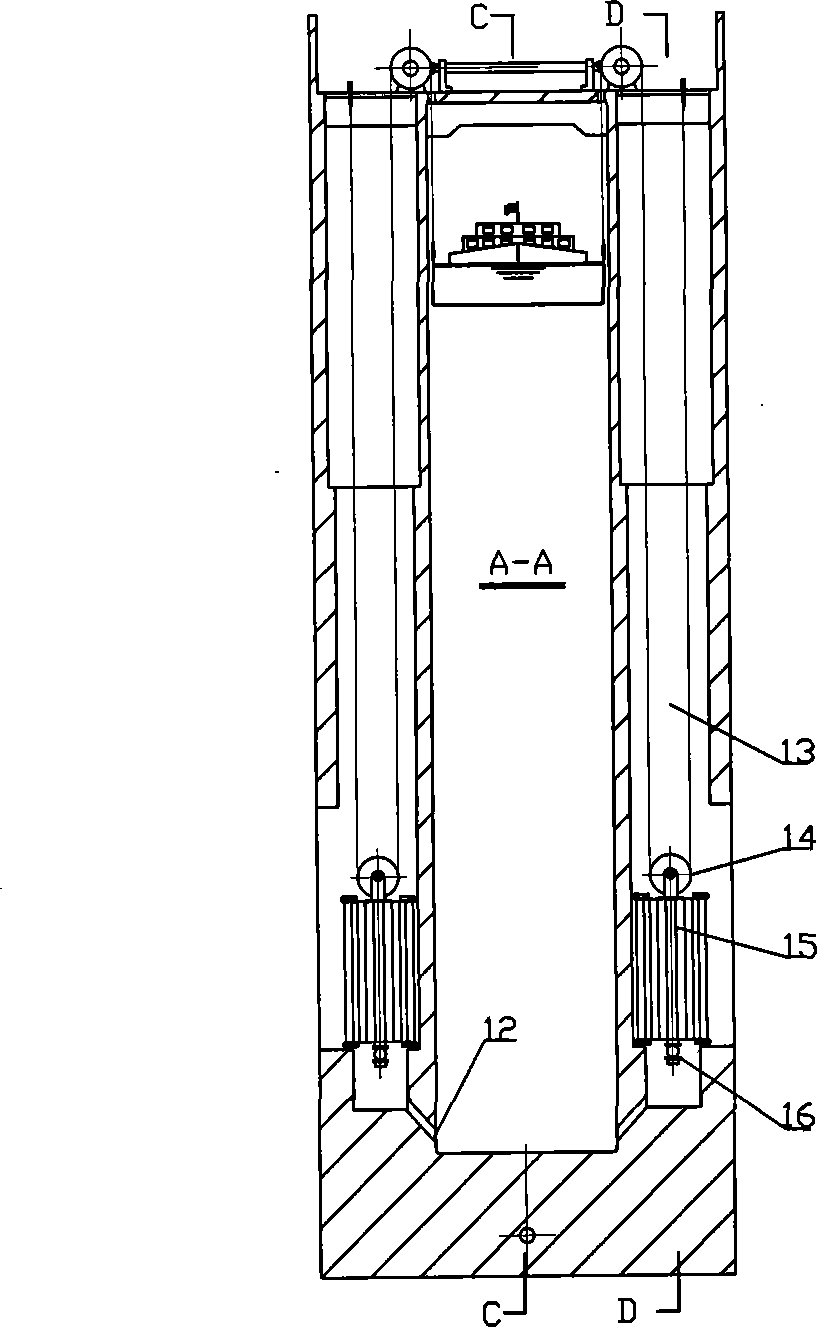

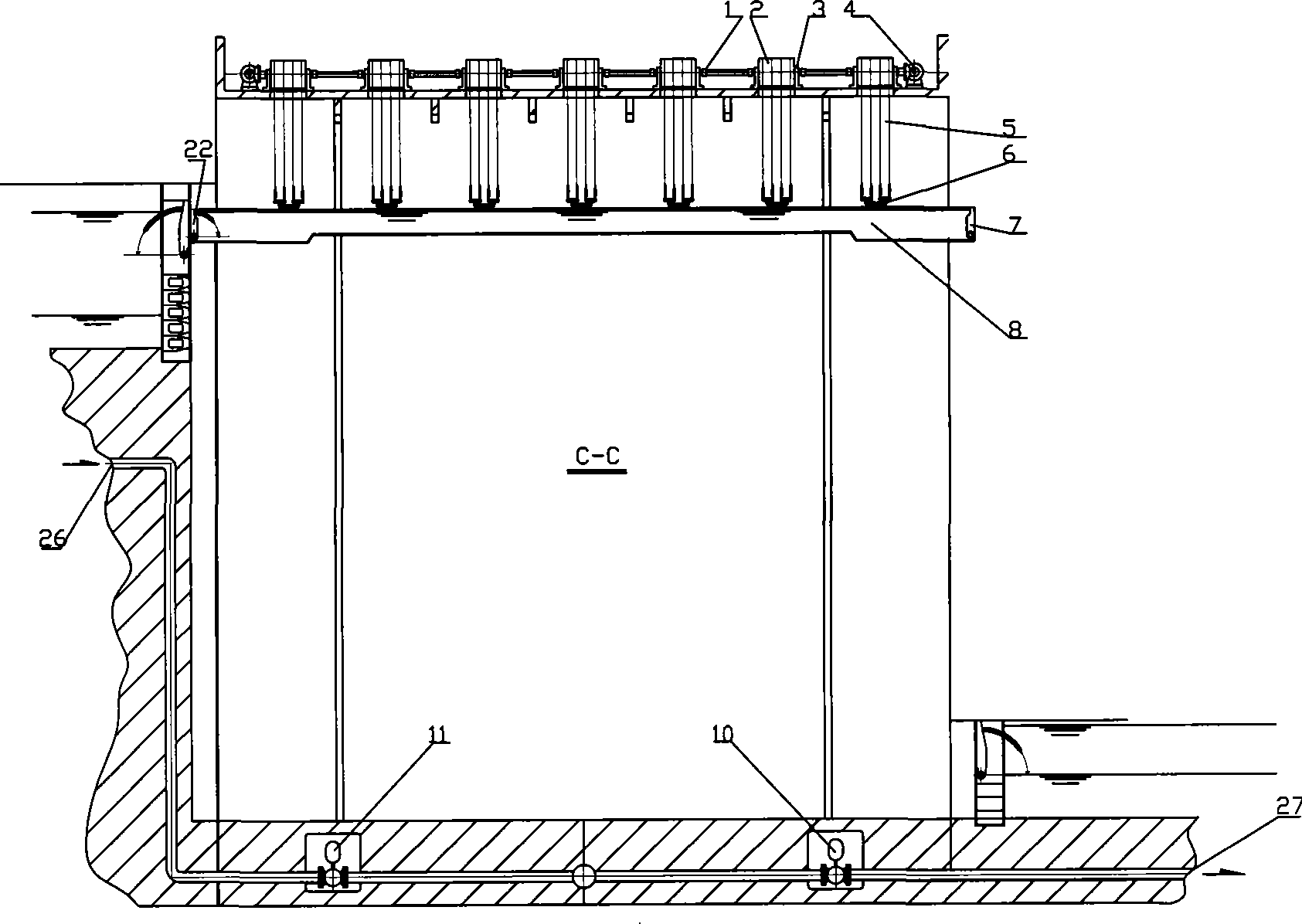

[0034] The working principle of the present invention is as follows: the total weight of the balance cylinder is used to balance the total weight of the ship's chamber, and by operating the water inlet valve or the drain valve, the lifting shaft is filled with water or the water in the lifting shaft is discharged to change the weight of the lifting balance cylinder , to overcome the frictional resistance and promote the purpose of lifting the ship.

[0035] 1 Balance device of hydraulic floating fast ship lift

[0036] The balance cylinder of the hydraulic floating torque balance heavy ship lift has both lifting and balancing functions. The balance barrel of the hydraulic floating fast vertical ship lift is not the same, as figure 1 As shown, it separates the lifting function of the balance cylinder from the balance function, so that one part of the balance cylinder is responsible for balancing, and the other part of the balance cylinder is responsible for lifting. The balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com