Technique for producing polyester filament yarn using false twisting distortion elasticizer

A technology of false-twist texturing and polyester filament, which is used in textiles and papermaking, etc., can solve the problems of short heating distance and time of coarse denier yarn, not good enough hand feeling, unfavorable uniform stretching, etc. , the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1——FDY process of producing fully drawn yarn, only stretching deformation is carried out, no false twist deformation.

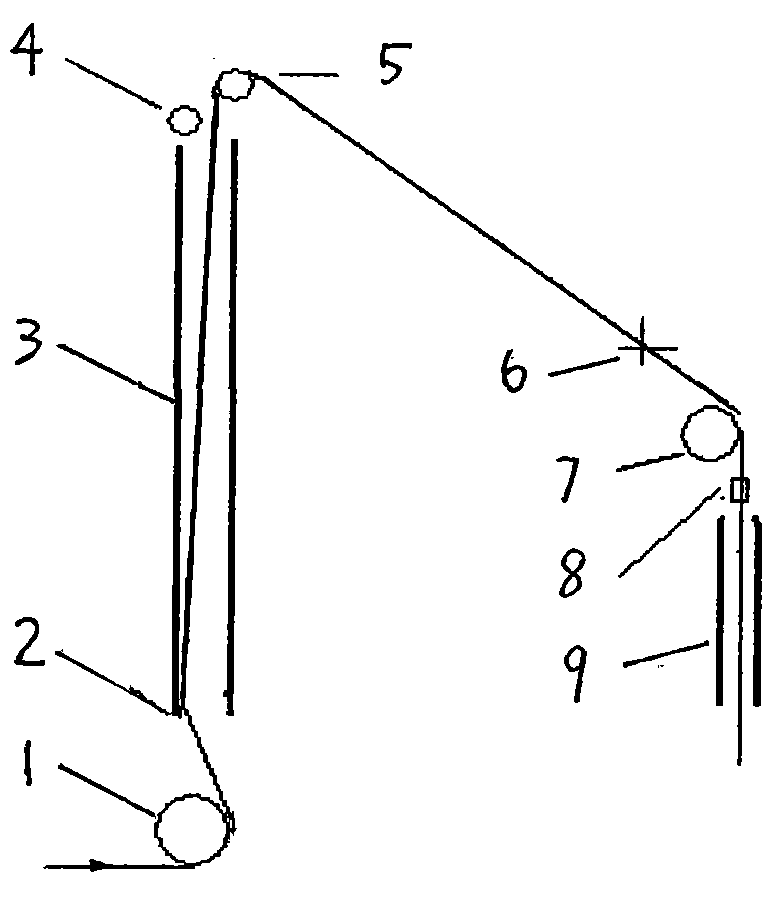

[0018] For its process, see figure 1 (without false twister 6): the processed raw material polyester pre-oriented yarn (POY) → first roller 1 → hot box entrance yarn guide 2 → first hot box 3 (non-contact heating) → steering yarn guide 5 → second roller 7 → Network nozzle 8 → Second heat box 9 → Three rollers → Oil tanker → Winding and forming to make FDY. Outlet yarn guide 4 is empty.

[0019] Specifically: Polyester pre-oriented yarn 630dtex / 96fPOY is fed from the original yarn frame through the wire guide tube to the first roller 1, enters the first hot box through the hot box entrance yarn guide 2, and enters the first hot box 3 After non-contact heating, it enters the second roller through the steering yarn guide 5 7. Stretch and deform between the first roller and the second roller, network through the network nozzle 8, and then ente...

Embodiment 2

[0020] Embodiment 2——FDY process for producing fully drawn yarn, only stretching deformation is carried out, no false twist deformation.

[0021] Its technological process is the same as above. Specifically, the polyester pre-oriented yarn 85dtex / 48fPOY is fed from the original yarn frame through the guide tube to the first roller 1, enters the first hot box through the hot box inlet guide 2, and enters the first hot box 3. After non-contact heating, it enters the second roller through the steering guide 5 7. Stretch and deform between the first roller 1 and the second roller 7, network and gather through the network nozzle 8, then heat setting in the second heat box 9, oil the tanker, and wind and shape. Among them, vehicle speed: 650m / min; stretch ratio: 1.75; network air pressure: 1.20kgf / cm 2 Second overfeeding: 4.50%; Three overfeeding: 7.20%; First heating box temperature: 82°C; Second heating box temperature: 120°C to obtain 50D / 48F FDY finished products.

Embodiment 3

[0022] Example 3——Production of polyester fiber filaments with high shape retention requirements such as degree of irregularity and hollowness

[0023] The process flow is shown in Figure 2 (using false twister 6), the processed raw material is hollow and other special-shaped cross-section polyester pre-oriented yarn (POY)→one roller 1→hot box inlet yarn guide 2→one hot box 3 (non-contact heating) → Turning yarn guide 5 → False twister 6 (low false twist deformation) → Second roller 7 → Network nozzle 8 → Second heating box 9 → Three rollers → Oil tanker → Winding and forming, to obtain polyester hollow with high fidelity performance, etc. Special-shaped cross-section low-elastic network wire. Outlet yarn guide 4 is empty.

[0024] Specifically, the polyester pre-oriented yarn 265dtex / 24f cross hollow POY is fed from the original yarn frame through the wire guide tube to a roller 1, enters a hot box 3 through the hot box entrance yarn guide 2, and enters a hot box 3 for non-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com