Agrobacterium strain and method for preparing left-lateral lactone compounds thereby

A technology of Agrobacterium and D-lactone, which is applied in the field of high-selectivity D-lactone hydrolase-producing bacteria, can solve the problems of environmental protection and economy, and achieve the effect of stable enzyme production and good stereoselectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

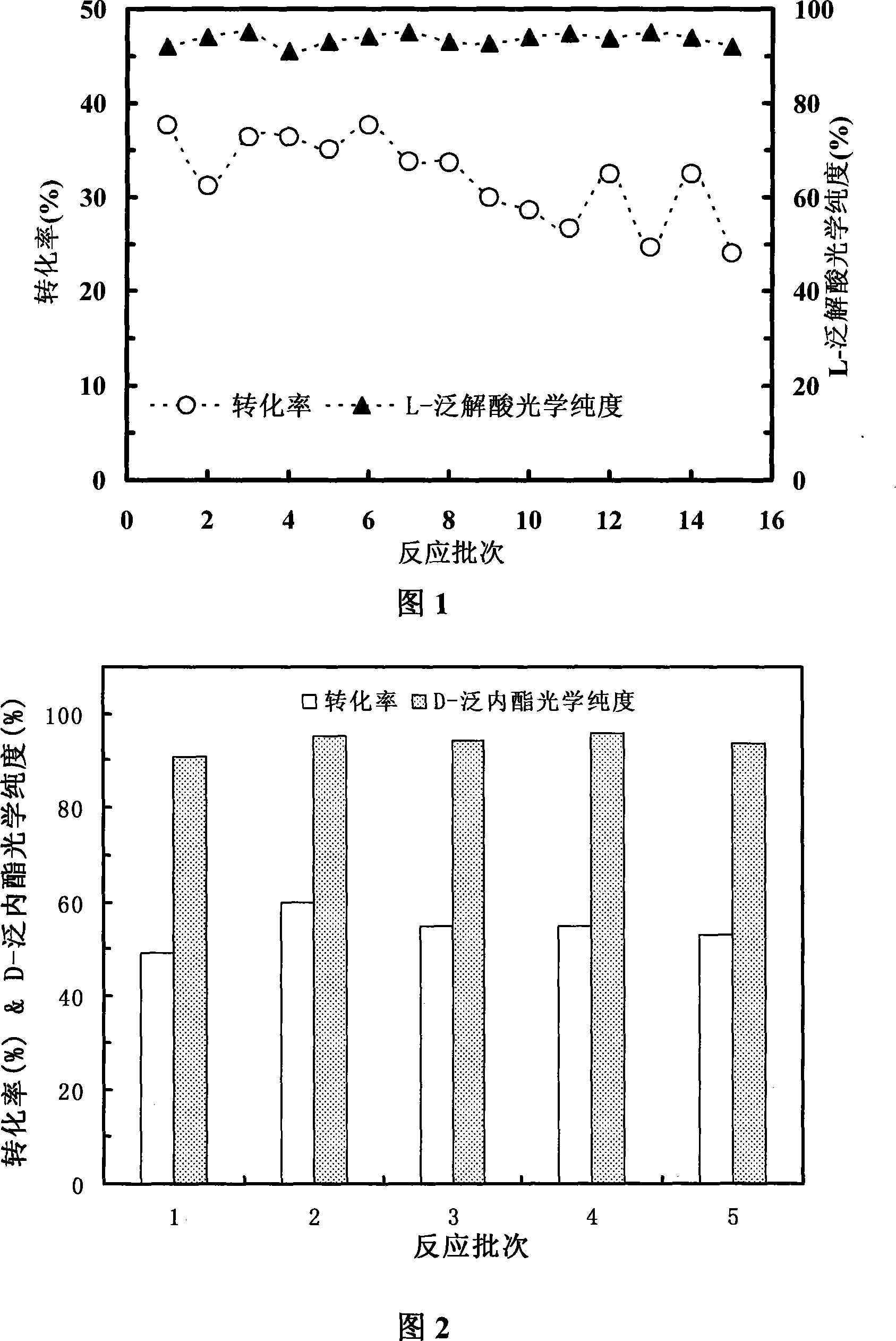

[0036] Example 1 Screening of Agrobacterium CGMCC 2371

[0037] Collected 400 soil samples under different environmental conditions, respectively using γ-butyrolactone, DL-pantotolactone, DL-sodium pantoate, or L-pantotolactone as the only carbon source for enrichment Cultivate and screen L(+)-lactonohydrolase-producing bacteria.

[0038] (1) Put the soil sample in a test tube, add 2mL enrichment medium A (g / L) (substrate 1.0, NaNO 3 4.0, KH 2 PO 4 4.0, MgSO 4 0.1, KCl 0.5, ZnSO 4 ·7H 2 O 0.1, CuSO 4 ·5H 2 O 0.05), at 30°C, 200r / min enrichment culture for 1 day, keep the test tubes with obvious signs of microbial growth, take 0.2mL enrichment culture solution from each tube, add 1.8mL sterilized enrichment medium B (g / L) (substrate 5.0, NaNO 3 4.0, KH 2 PO 4 4.0, MgSO 4 0.1, KCl 0.5, ZnSO 4 ·7H 2 O 0.1, CuSO 4 ·5H 2 O 0.05), culture at 30°C, 200r / min for 1-2 days, take 0.1mL enriched culture solution from each tube and spread it on plate medium C (...

Embodiment 2

[0041] The fermentation culture of embodiment 2 Agrobacterium CGMCC 2371

[0042] Slant and plate medium (g / L): glycerol 30, yeast extract 7.5, peptone 7.5, agar 20. Sterilize at 121°C for 15 minutes, cool down after sterilization, plate, inoculate, and incubate at 30°C for 1 day. Fermentation medium (g / L): 20 dextrin; 10 glycerol; 10 peptone; 10 yeast extract; Fermentation is carried out under the condition of 160r / min, and the dry weight of the bacteria reaches 5.2g / L after 36 hours of culture, the enzyme production can reach more than 366U / L, and the specific activity is 70U / g.

Embodiment 3

[0043] The immobilization of embodiment 3 Agrobacterium CGMCC 2371 cells

[0044] 1) Take 5 g of wet cells of Agrobacterium CGMCC 2371, add 15 mM glutaraldehyde, cross-link at 30° C. for 3 h, and then centrifuge to obtain immobilized cells. After the cells are immobilized, the activity recovery rate of the enzyme is generally above 90%.

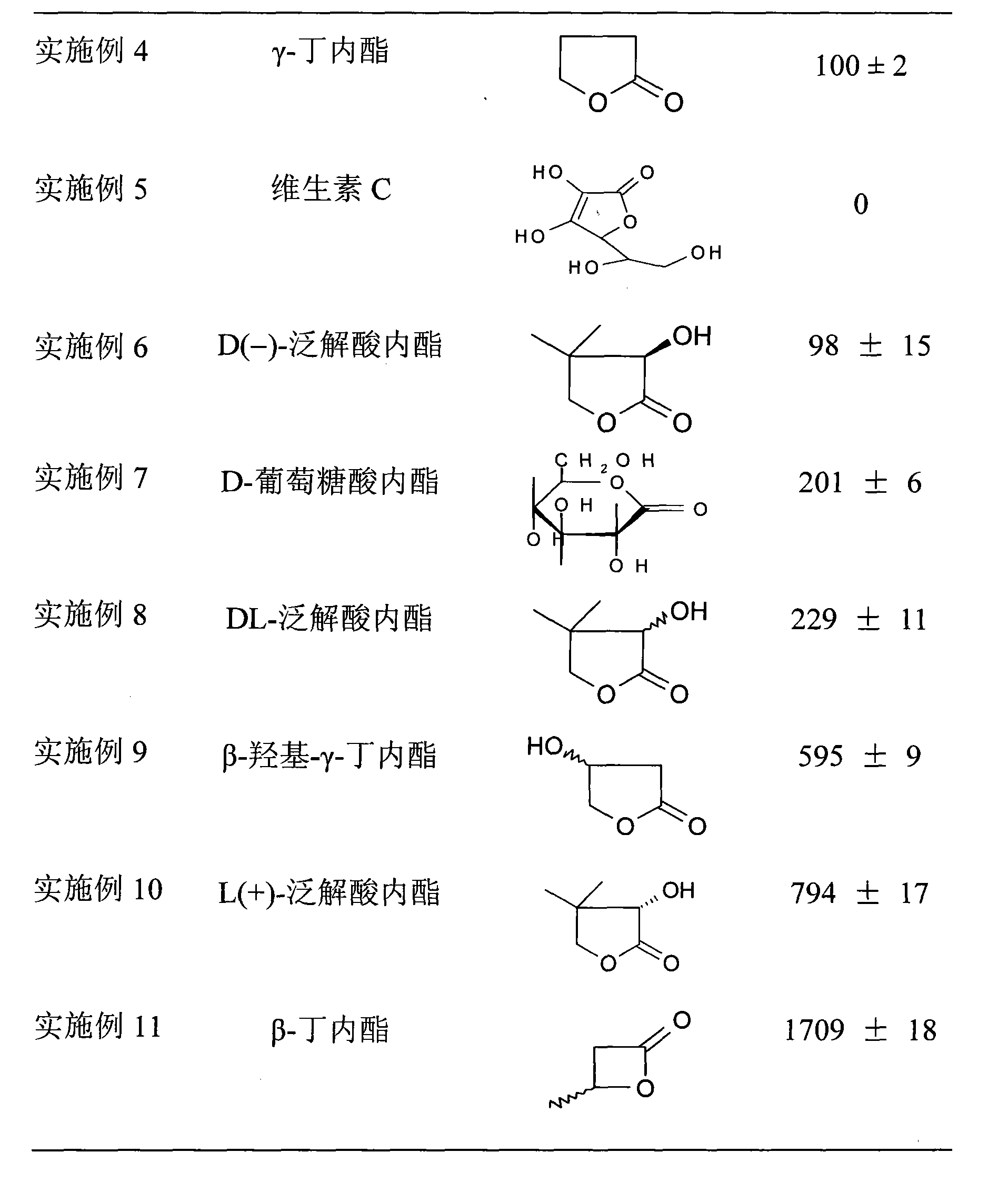

[0045] 2) A series of lactones in the following list 1 are substrates, and the substrate concentration is 100 mM , with a reaction volume of 10 mL, 1 g of immobilized cells were added, and the catalytic activity was measured after reacting for 0.1 to 0.5 h at 30°C under magnetic stirring. Table 2 lists the relative viability of immobilized cells when different lactones are hydrolyzed. Taking the activity of γ-butyrolactone as 100%, the hydrolysis effect of immobilized cells on lactones with relatively complex structures (such as vitamin C) is not obvious. When the substrate is β-butyrolactone, the viability of immobilized cells is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com