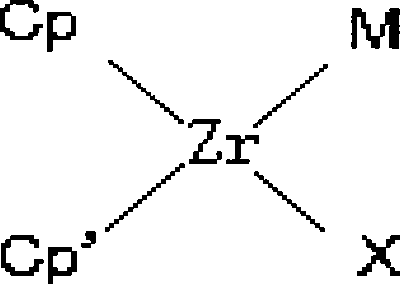

Boroxol cyclopentadienyl zirconium metal catalyzer and preparation method and application thereof

A metal catalyst and boroxy zirconocene technology are applied in the field of boroxy zirconocene metal olefin polymerization catalysts and their preparation fields, which can solve the problems of inability to synthesize ethylene-propylene rubber activity, low solubility and limit the application of metallocene catalysts, and achieve synthesis Inexpensive raw materials, excellent solubility, catalyst stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Preparation of racemic ethyl-bridged bis-indenylboronate diisooctyl zirconium chloride.

[0015] Add 50 milliliters of ethylene glycol dimethyl ether (anhydrous), 0.4185 grams of racemic ethyl bridged bisindene zirconium dichloride to the stirred reaction flask of 100 milliliters that has been treated with anhydrous and anaerobic treatment. A mixed solvent of 0.2860 g of diisooctyl borate and 0.0790 g of pyridine (diluted with 20 ml of hexane) was added dropwise, and reacted for 8 hours to generate a yellow solution. Filtration and evaporation of the filtrate gave 0.6586 g of a yellow solid. Molecular formula C 36 h 50 BO 3 ClZr, the molecular weight is 668.36. Elemental analysis (%), measured value (theoretical value): C, 64.61 (64.64); H, 7.49 (7.48); chemical analysis: Cl (wt%), measured value (theoretical value): 5.28 (5.31).

Embodiment 2

[0017] Add 50 ml of hexane, 0.4 ml of ethyl aluminoxane (2.5M hexane solution), and 0.4 ml of isobutylaluminum into a 200 ml reaction flask with a bottom tube and agitation after anhydrous and anaerobic treatment. Oxane (2.5M hexane solution), warming up to 50°C, adding 1 ml of the catalyst synthesized in Example 1 (0.0668 g of catalyst dissolved in 100 ml of hexane solution), and feeding ethylene and propylene mixed gas through the dip tube (weight ratio 1:2.5), react at normal pressure for 1 hour, stop ventilation. Add 5 ml of 10% hydrochloric acid ethanol solution to terminate the reaction. Wash with 20% alkaline solution, and evaporate the solvent in vacuo to obtain 8.1330 g of ethylene-propylene rubber. The catalytic efficiency is 8.13×10 6 g ethylene propylene rubber per mole of catalyst. per hour.

Embodiment 3

[0019] Preparation of diisooctyl borate zirconocene chloride.

[0020] Add 50 milliliters of ethylene glycol dimethyl ether (anhydrous) and 0.2920 grams of zirconocene dichloride to a 100 milliliter stirred reaction flask that has been treated with anhydrous and anaerobic treatment, and add 0.2860 diisooctyl borate dropwise at a uniform speed within 20 minutes. gram, pyridine 0.0790 gram mixed solvent (diluted with 20 milliliters of hexane), reacted for 8 hours, and generated a yellow solution. After filtration and evaporation of the filtrate, 0.5351 g of yellow viscous liquid was obtained. Molecular formula C 26 h 44 BO 3 ClZr, the molecular weight is 541.67. Elemental analysis (%), found value (theoretical value): C, 57.61 (57.60); H, 8.09 (8.12); chemical analysis: Cl (wt%), found value (theoretical value): 6.55 (6.54).

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com