Method for refining pyromellitic anhydride by solvent

A technology for refining pyromellitic dianhydride and solvents, which is applied in organic chemistry and other fields, and can solve problems such as harsh environment, complicated operation, and difficulty in realizing industrialized production, and achieve the effects of less equipment, short process flow, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

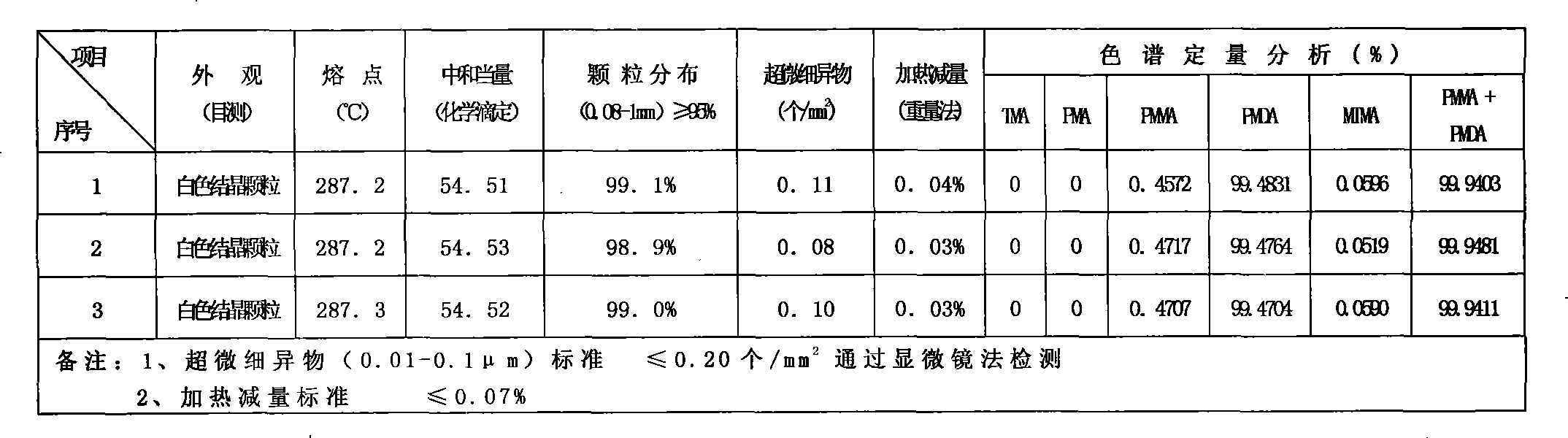

Embodiment 1

[0025] Add 97.2% crude pyromene directly obtained and sold from durene raw material through air catalytic oxidation by Wuhan Hannan Tongxin Chemical Co., Ltd. 108kg of formic anhydride, 600kg of acetic anhydride with a content of 98.9%, and 12kg of activated carbon, that is, the feeding ratio is 9:50:1. After the feeding is completed, the upper cover of the feeding manhole is closed, and the stirring is started. At the same time, the steam valve is opened to allow steam to enter the enamel kettle clamp. Start heating the cover, keep the temperature of the material in the enamel kettle at 125°C and react for 110 minutes under constant stirring. After the reaction is over, start to vacuumize the enamel crystallization kettle. The material is introduced into the pipeline by the preferred but not limited to the JLBF type composite bag fine filter produced and sold by Qidong Julong Petrochemical Equipment Co., Ltd. In the jacketed enamel crystallization kettle, while stirring, pass...

Embodiment 2

[0027] Add 97.7% crude pyromellitidine directly obtained and sold by air catalytic oxidation of durene raw material by Wuhan Hannan Tongxin Chemical Co., Ltd. Acid anhydride 72kg, after carrying out a PMDA refining reaction, content is 95.6% acetic anhydride 540kg, active carbon 9kg, promptly charging ratio is 8: 60: 1, after feeding completes, close the feeding manhole loam cake, open and stir, open steam valve simultaneously Steam enters the jacket of the enamel kettle to start heating. Keep the temperature of the material in the enamel kettle at 118°C and react for 90 minutes under constant stirring. After the reaction, start to vacuum the enamel crystallization kettle. When the vacuum reaches 0.08MPa, open the bottom of the enamel reaction kettle Valve, the material in the kettle is introduced from the pipeline to the preferred but not limited to JLBF type composite bag fine filter produced and sold by Qidong Julong Petrochemical Equipment Co., Ltd., Jiangsu Province, China...

Embodiment 3

[0029] Add 97.2% crude pyromellitidine directly obtained and sold by air catalytic oxidation of durene raw material by Wuhan Hannan Tongxin Chemical Co., Ltd. 56 kg of acid anhydride, 440 kg of 93.2% acetic anhydride and 12 kg of active carbon after the secondary PMDA refining reaction, that is, the feeding ratio is 7: 55: 1.5. After the feeding is completed, the upper cover of the feeding manhole is closed, the stirring is started, and the steam valve is opened simultaneously. Let the steam enter the jacket of the enamel kettle to start heating, keep the temperature of the material in the enamel kettle at 112°C and react for 120 minutes under constant stirring. After the reaction is completed, start the enamel / vacuum. When the vacuum reaches 0.08MPa, open the bottom valve of the enamel reaction kettle , the material in the kettle is introduced into the preferred but not limited to JLBF composite bag-type fine filter produced and sold by Qidong Julong Petrochemical Equipment Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com