Relay valve

A relay valve and valve body technology, applied in the direction of brakes, brake components, control valves and air release valves, can solve the problems of unfavorable braking of heavy vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

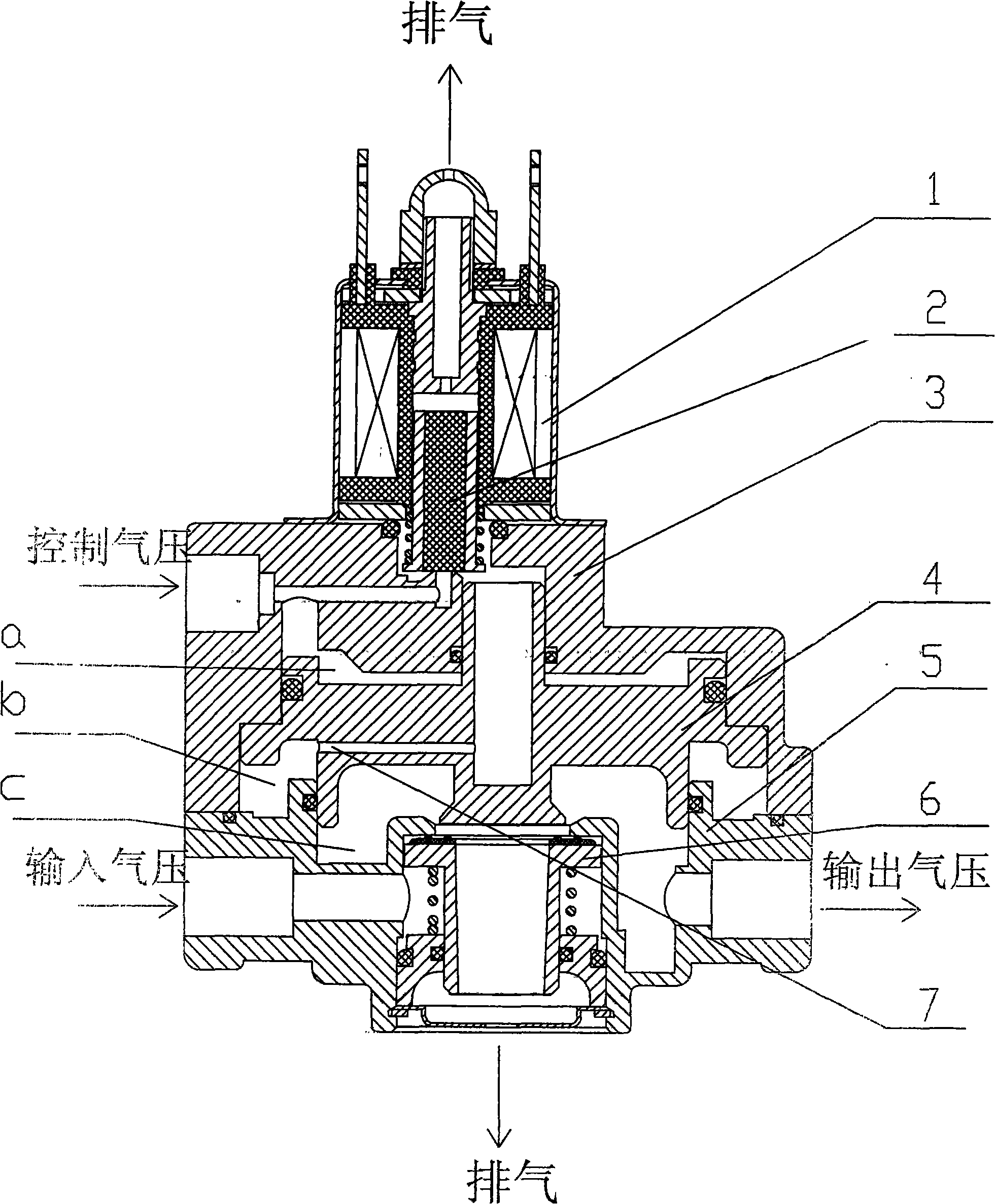

[0010] exist figure 1 Among them, when the vehicle is unloaded, a relay valve of the present invention acts as a general relay valve. At this time, the solenoid valve works, and the core rod 2 of the solenoid valve 1 moves away from the valve port at the lower end and seals the solenoid valve. The vent hole on the top, the control air pressure enters the air cavity 1 from the control air pressure inlet and passes through the middle cavity of the piston 4, and then enters the air cavity 2 through the small hole 7. Under the action of the air pressure, the piston 4 moves down to open the valve 6, input After the air pressure enters the air chamber 3, it forms an output air pressure to the brake cylinder; due to the counteracting effect of the air chamber 2, the upper and lower acting areas of the piston 4 are nearly equal, and the output air pressure is close to the control air pressure. At this time, the relay valve is different from the general relay valve. Works the same.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com