Technique for producing sulfonic acid firming agent for foundry by industry waste material-sulfonic acid mother liquor

A technology of industrial waste and sulfonic acid mother, applied in casting molding equipment, casting molds, manufacturing tools, etc., can solve the problems of large working environment in workshops, rising production costs, and high costs, and achieve simple production process and process operation control. , The effect of reducing the processing cost and the excellent performance of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

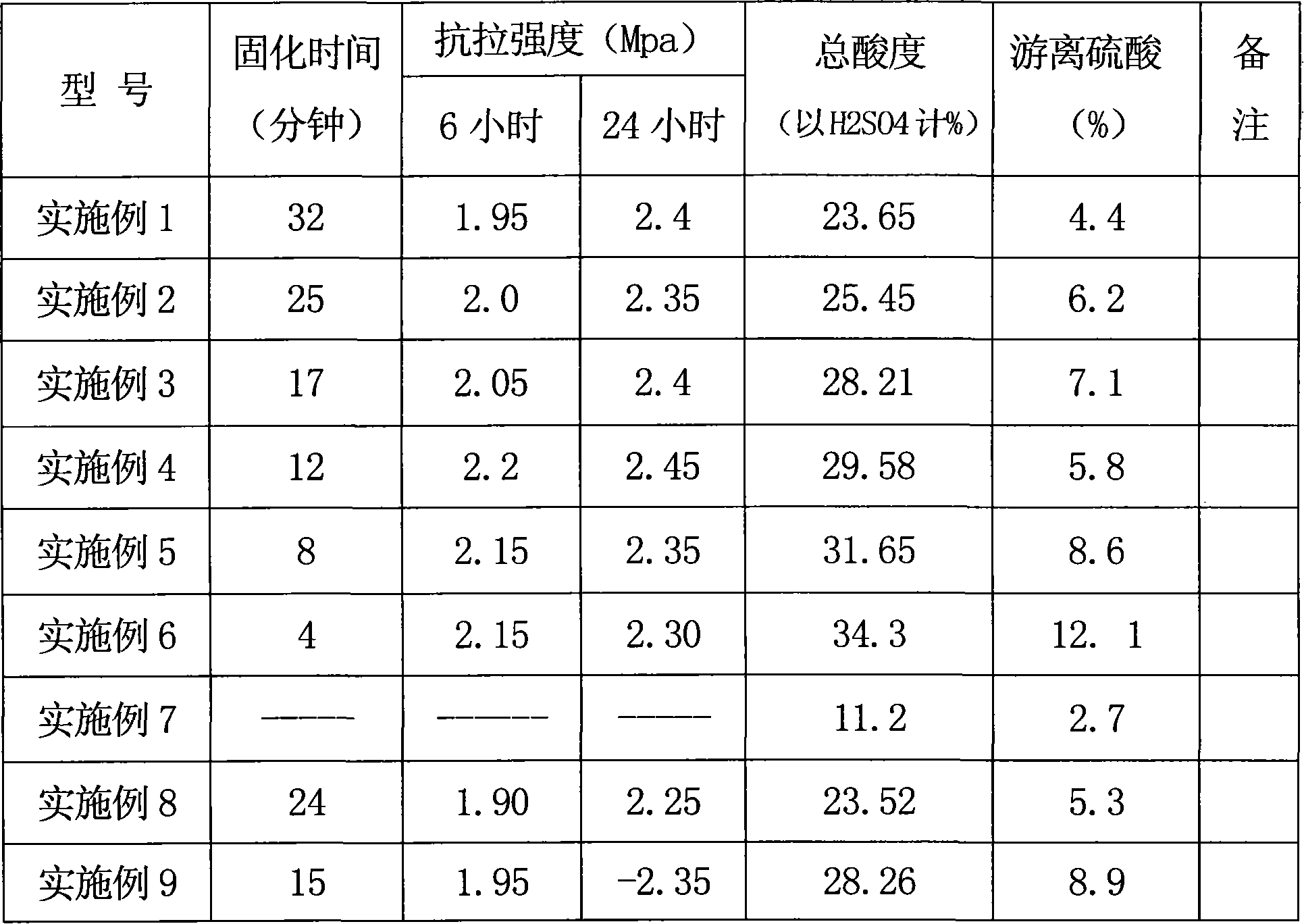

Examples

Embodiment 1

[0016] Embodiment 1, sulfonic acid curing agent NFG-111

[0017] NFG-111 is a sulfonic acid aqueous solution curing agent, the appearance is light yellow or light brown transparent liquid. Applied in summer high temperature season (above 25°C).

[0018] Add 70 grams of xylene into the four-neck flask, slowly add 126 grams of concentrated sulfuric acid, start stirring and raise the temperature to 120°C-125°C, keep the temperature for 2 hours, and carry out vacuum dehydration and debenzene reaction after the heat preservation is completed. The temperature is -0~-0.08MPa, and the temperature is below 130°C until no liquid flows out. After the dehydration and debenzene reaction, start to lower the temperature, and start to add 15 grams of ethanol and 60 grams of water when the temperature is lower than 70 ° C, and stir evenly to obtain about 270 grams of solidifying agent slurry. Add 295 grams of the pretreated sulfonic acid mother liquor into the above-mentioned four-neck flask...

Embodiment 2

[0020] Embodiment 2, sulfonic acid curing agent NFG-112

[0021] NFG-112 is a sulfonic acid aqueous solution curing agent, the appearance is taupe transparent liquid. It is suitable for low temperature in summer or high temperature in spring and autumn (20°C-25°C).

[0022] Add 70 grams of xylene into the four-necked flask, slowly add 135 grams of concentrated sulfuric acid, start stirring and raise the temperature to 110°C-140°C, keep the temperature at this temperature for 2 hours, and carry out vacuum dehydration and debenzene reaction after the heat preservation is completed. The temperature is -0~-0.08MPa, and the temperature is below 130°C until no liquid flows out. After the dehydration and debenzene reaction, start to lower the temperature, and start to add 15 grams of ethanol and 50 grams of water when the temperature drops below 70 ° C, and stir evenly to obtain about 276 grams of solidifying agent slurry. Add 298 grams of pretreated sulfonic acid mother liquor int...

Embodiment 3

[0023] Embodiment 3, sulfonic acid curing agent NFG-113

[0024] NFG-113 is a sulfonic acid aqueous solution curing agent, the appearance is taupe transparent liquid. Applied in spring and autumn seasons with lower temperature (15°C-20°C).

[0025] Add 70 grams of xylene into the four-necked flask, slowly add 148 grams of concentrated sulfuric acid, start stirring and raise the temperature to 110°C-140°C, keep the temperature at this temperature for 2 hours, and carry out vacuum dehydration and debenzene reaction after the heat preservation is completed. The temperature is -0~-0.08MPa, and the temperature is below 130°C until no liquid flows out. After the dehydration and debenzene reactions are completed, start to lower the temperature, and start adding 15 grams of ethanol and 40 grams of water when the temperature drops below 70°C, and stir evenly to obtain about 270 grams of solidifying agent stock. Add 289 grams of pretreated sulfonic acid mother liquor into the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com