Method using laser quick forming producing HA/Ti gradient biological activity material

A laser rapid prototyping and bioactive technology, applied in the medical field, can solve the problems of difficult control of the product phase composition, residual thermal stress, discontinuous process flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

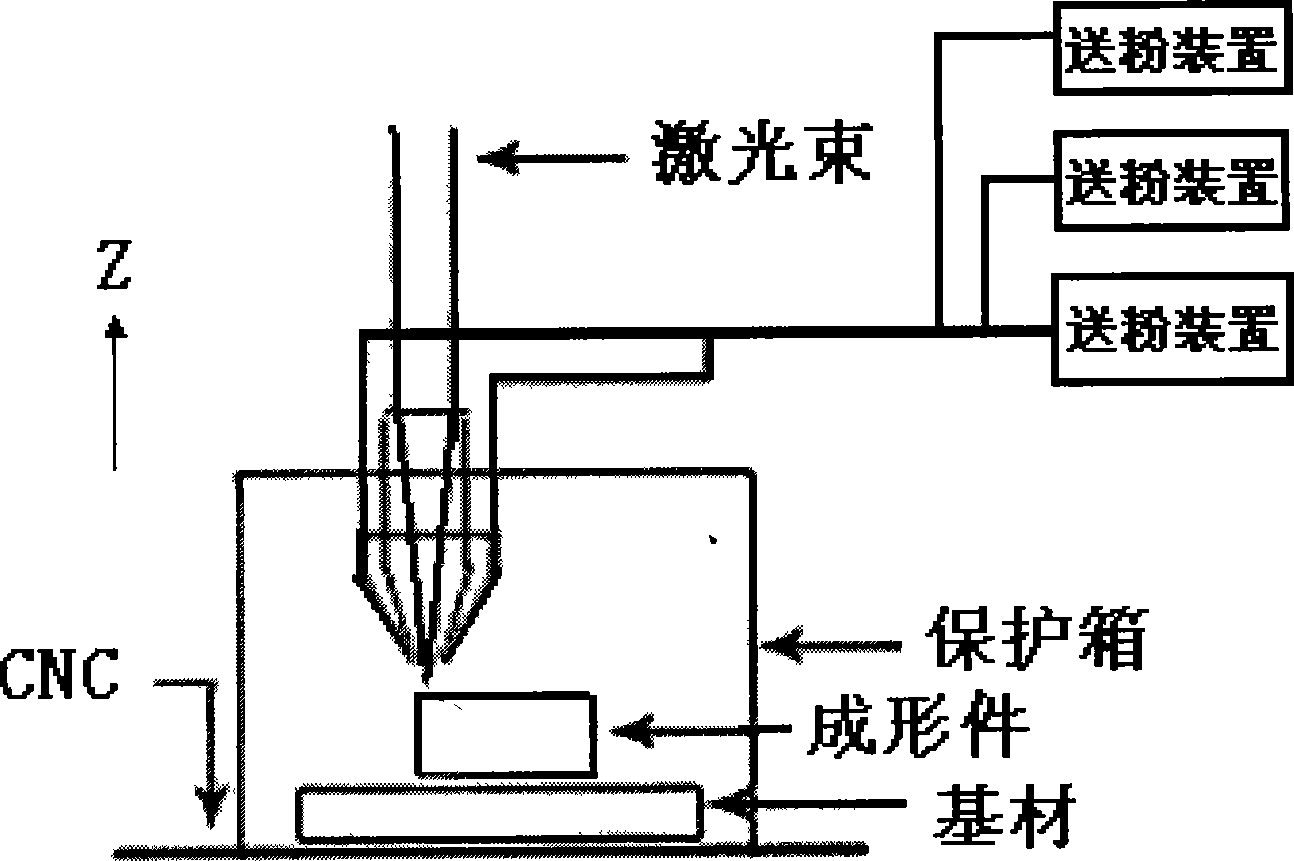

[0029] 5.1 Laser plus equipment

[0030] see figure 1 , Laser processing equipment includes lasers, two-way or three-way powder feeders, substrates, molten pools, CNC workbenches (CNC), and protection boxes.

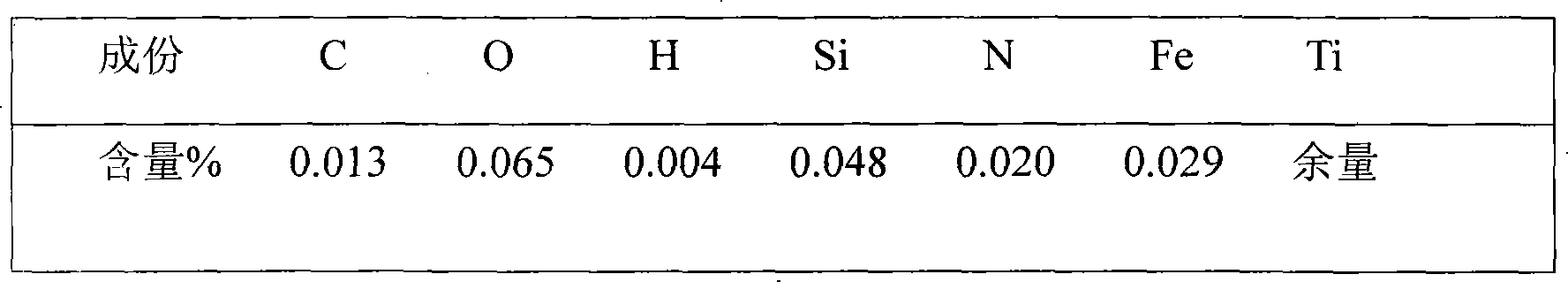

[0031] 5.2 Experimental materials

[0032] Choose pure titanium powder with a particle size of 100-300 mesh, as well as CaHPO4·2H2O and CaCO3 powder. All powder particles are spherical and have good fluidity. The range of powder feeding volume is 1-10g / min, and the powder feeding accuracy is controlled at ±3%. The base material is pure titanium with a thickness of 4mm to 8mm.

[0033] 5.3 Experimental method

[0034] The base material is pure titanium (TA2) forged plate (140mm×60mm×6mm). Before the experiment, the surface of the plate was polished with No. 200 sandpaper and then cleaned with acetone to decontaminate. Put the powder into the two-way or three-way automatic powder feeder respectively. Adjust the output of powder, pure titanium powder in accordance wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com