Chip testing classifier

A chip testing and sorting machine technology, applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve problems such as defects and reduce test quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the present invention, now give a preferred embodiment and cooperate with the drawings, as follows in detail:

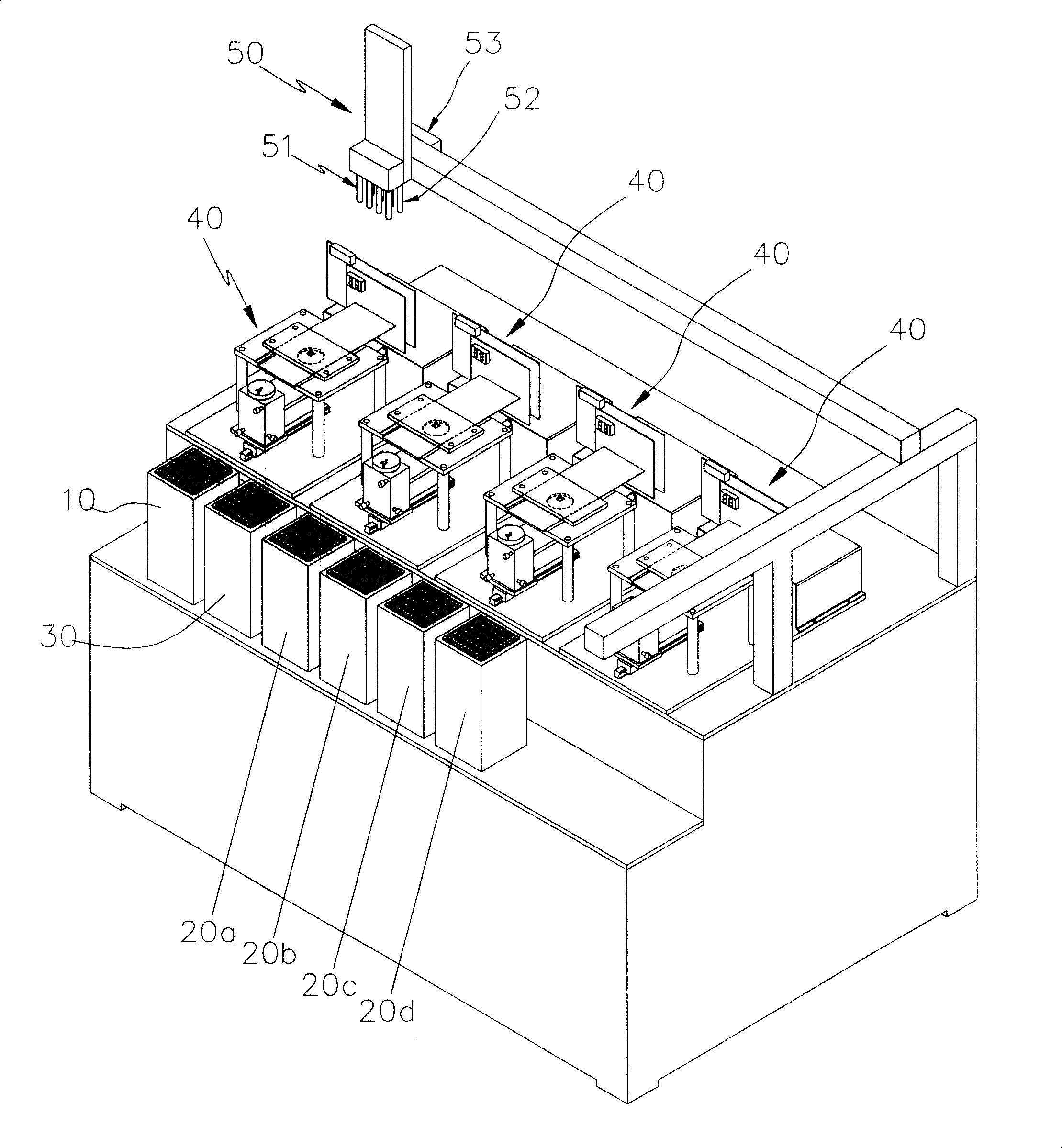

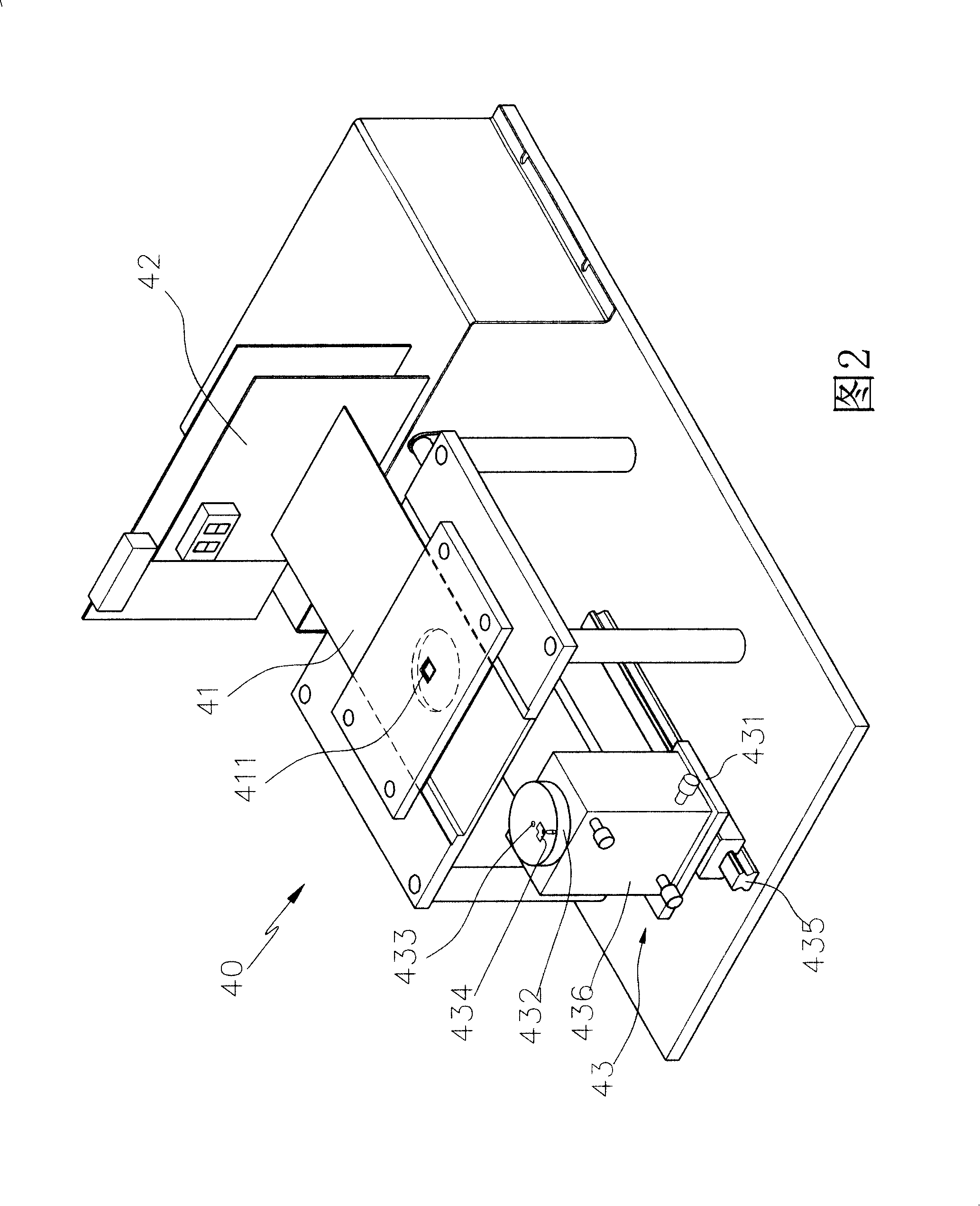

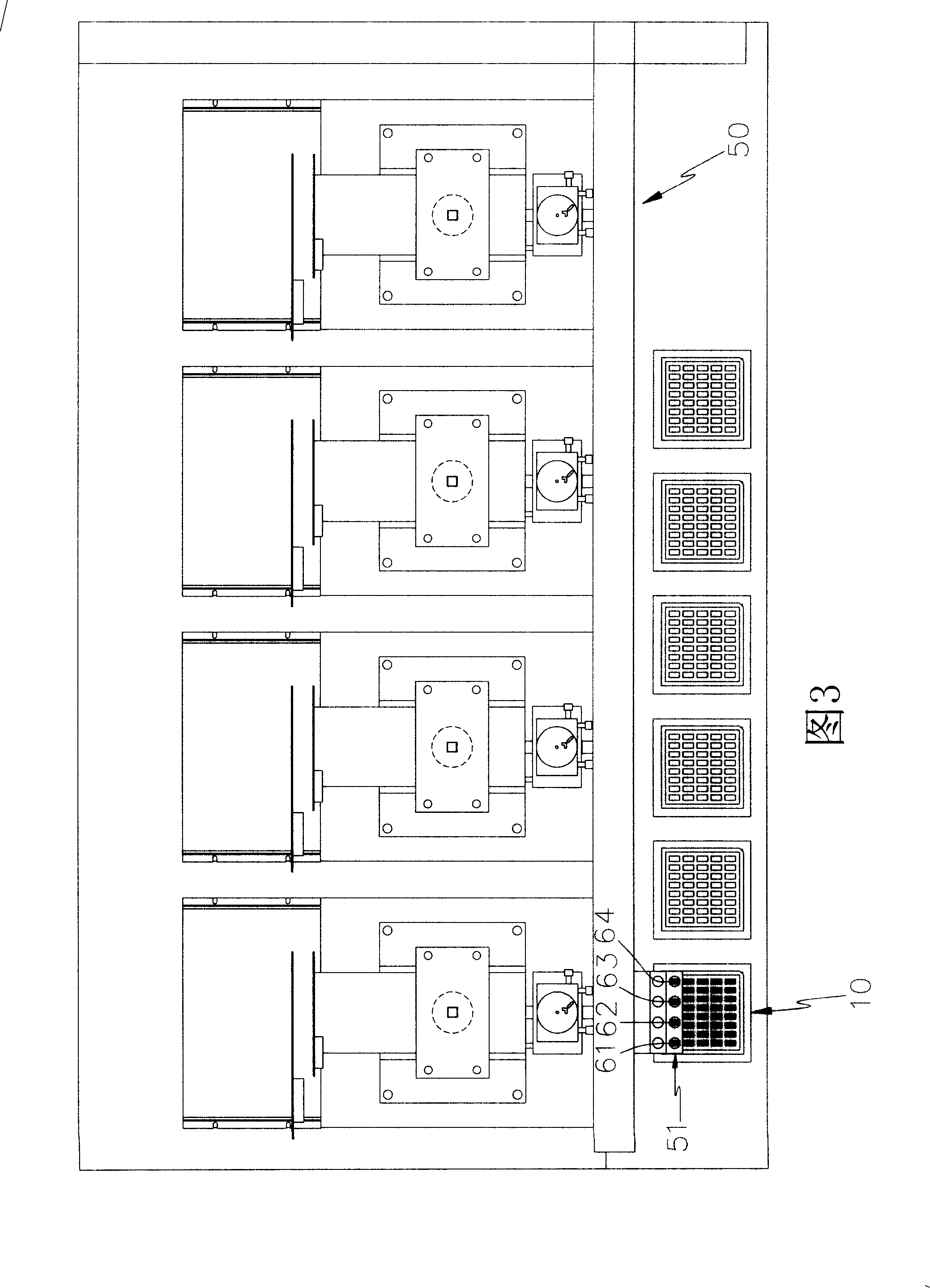

[0022] see figure 1 , shown in Fig. 2, described chip test classifier is to be provided with feeding box 10, receiving box 20a, 20b, 20c, 20d and empty box 30 at the front end of machine platform, wherein, described feeding box 10 is to hold Set at least one tray containing the chips to be tested, which can drive the tray up and down for retrieving materials, and the receiving box can be subdivided into different levels of receiving boxes 20a, 20b, 20c, 20d, each receiving box 20a, 20b, 20c, and 20d are used to store different grades of chips that have been tested. The empty box 30 can receive the empty trays used up by the supply box 10, and stack the empty trays by lifting and shifting them. It can also be used as needed. Lift and shift the received empty trays for replenishment in the receiving boxes 20a, 20b, 20c, and 20d fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com