Wireless projection type welding mask and welding machine provided with same

A welding mask and wireless projection technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve problems such as affecting the normal use of welding masks, restricting the operator's welding work, poor signal connection, etc., to improve work convenience. , to ensure discomfort, save the effect of restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the various figures of the application, structurally identical or functionally similar features are indicated by the same reference numerals.

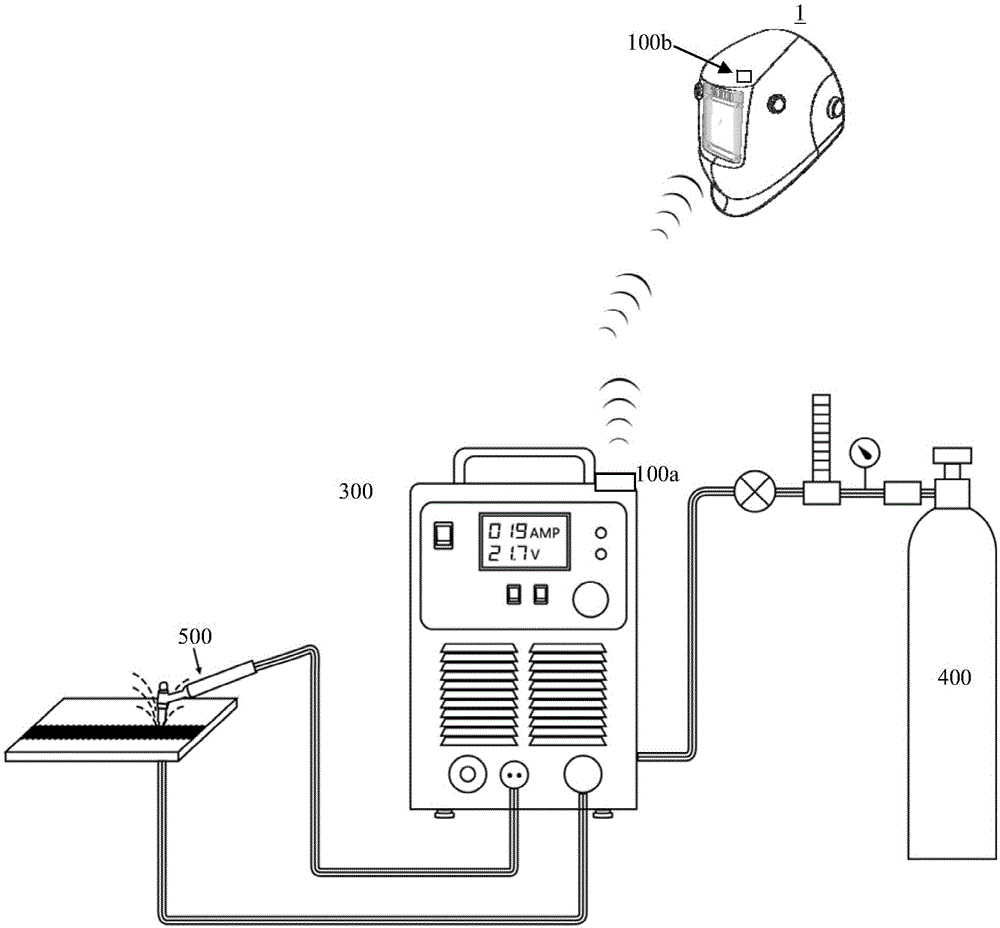

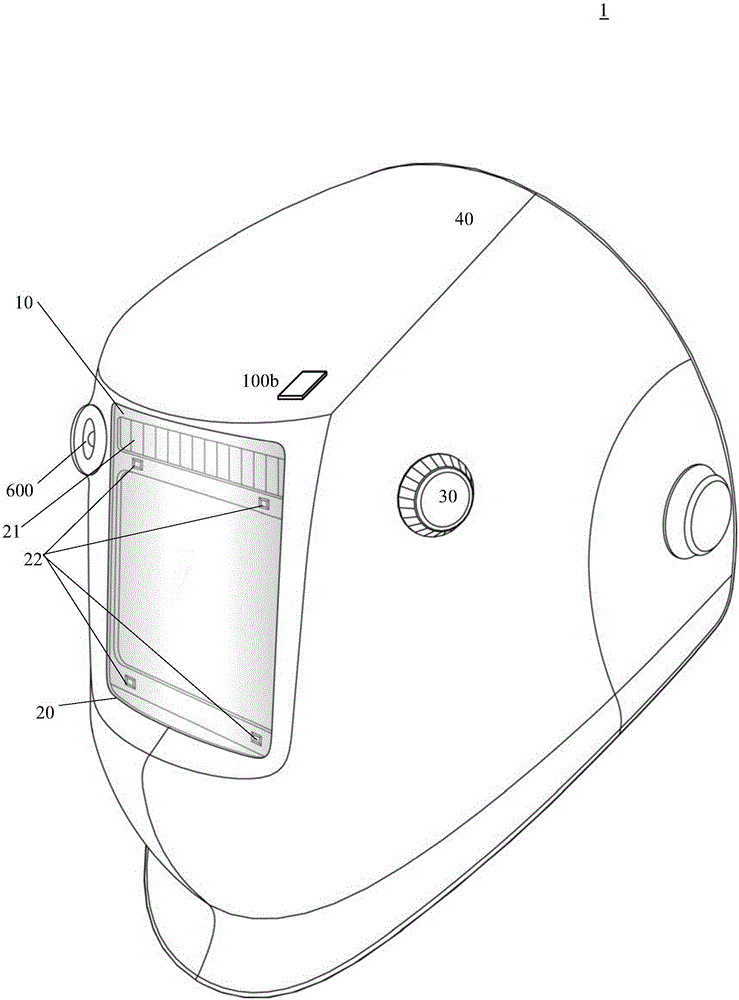

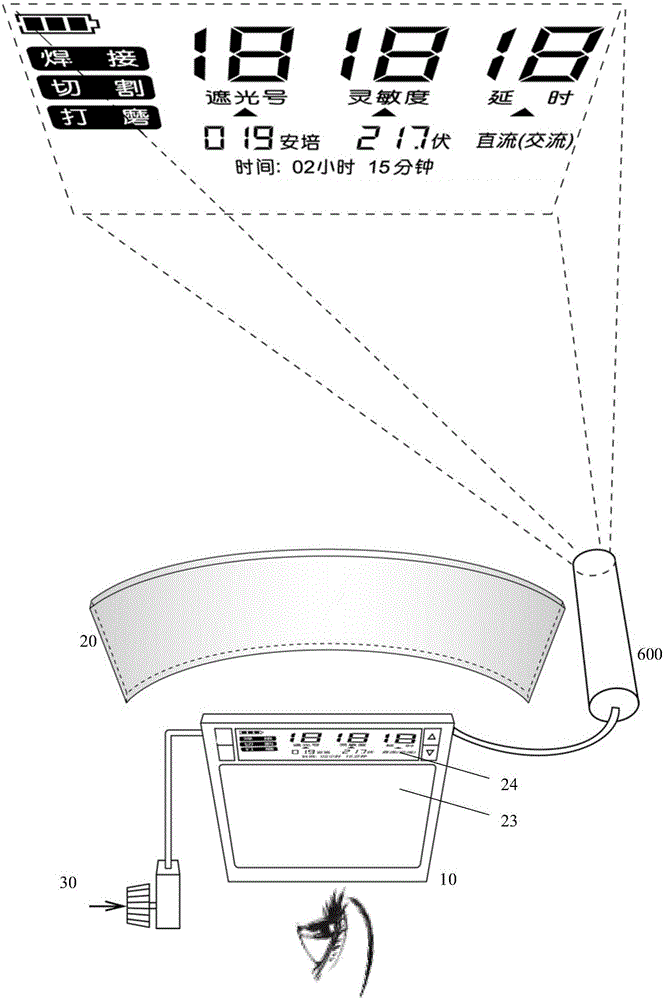

[0039] figure 1 An exemplary embodiment of the welding device of the invention is shown schematically. The welding equipment includes an electric welder 300 , a gas cylinder 400 (such as an argon gas cylinder) and a welding torch 500 . The welding machine 300 , the gas cylinder 400 and the welding torch 500 are connected via cables known in the art. In addition, the welding equipment also includes, for example, a wireless communication module 100 a provided on the electric welding machine 300 . This wireless communication module 100a and electric welding machine circuit 301 (as Figure 4 As shown), it can be used to send out signals related to the operating parameters of the welding machine such as current size, voltage size, DC or AC display, and working time of the welding torch, etc., and can set the welding machine cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com