Mn-Zn soft magnetic ferrite and production method

A soft ferrite, mn-zn technology, applied in inductor/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve problems such as low permeability, power consumption, and increased coil copper wire loss, etc. Achieve high saturation magnetic flux density and small permeability change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

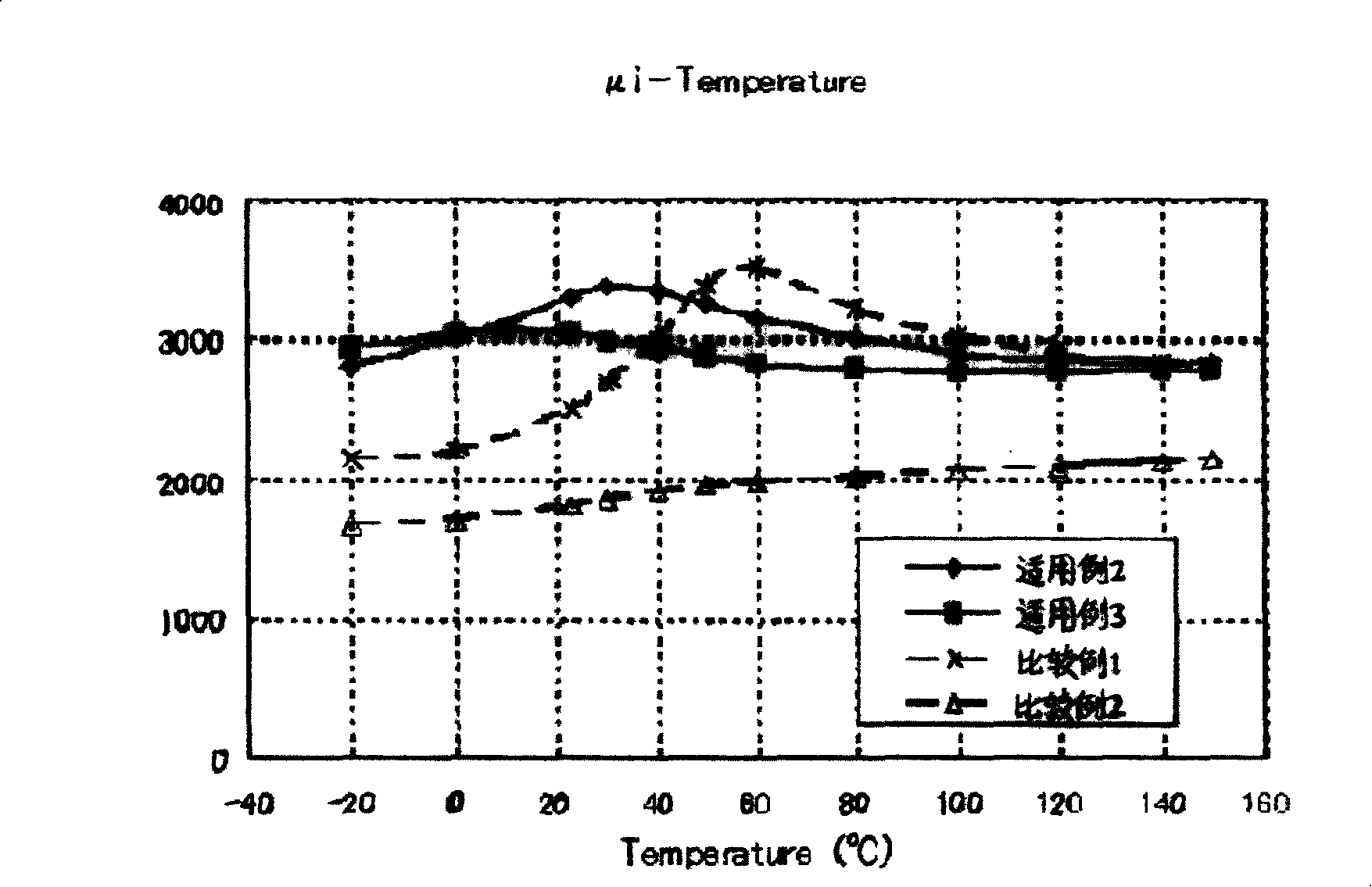

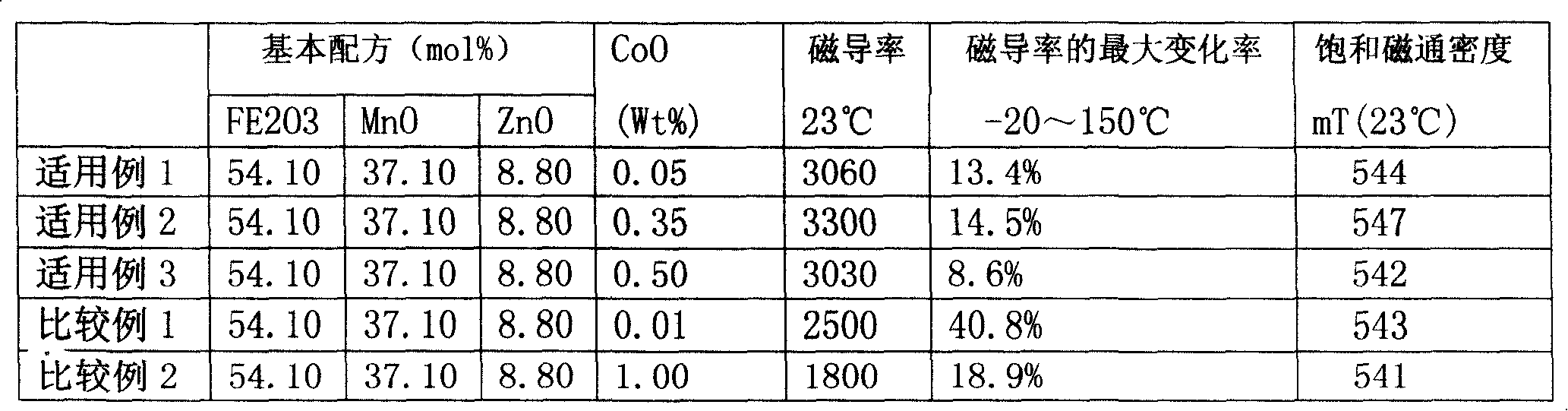

[0026] Embodiment 1: a kind of Mn-Zn system soft magnetic ferrite, mainly by Fe 2 o 3 , Mn 3 o 4 and ZnO composition, where Mn 3 o 4 Calculated by MnO, by Fe 2 o 3 : 54.1mol%, MnO: 37.1mol% and ZnO: 8.8mol% are measured and mixed, pre-calcined with a push-type pre-sintered furnace (950 ° C × 2 hours), after 20 minutes of pulverization, and then dopant: SiO 2 : 0.005wt%, CaO: 0.04wt%, Nb 2 o 5 : 0.02wt%, V 2 o 5 : 0.05wt%, dopant wt% refers to Fe 2 o 3 , Mn 3 o 4 and the total weight ratio of ZnO.

[0027] Simultaneously add the CoO of dopant as following table 1 and drop into sand mill (CoOwt% in table 1 refers to relative to Fe 2 o 3 , Mn 3 o 4 and the total weight ratio of ZnO. )

[0028] Add additives according to the following ratio: deionized pure water: 40-50wt%, binder: 0.5-1.5wt%, dispersant: 0.1-0.5wt% and defoamer: within 0.1wt% and the value is greater than zero, carry out For sanding, additive wt% refers to Fe 2 o 3 , Mn 3 o 4 and the tota...

Embodiment 2

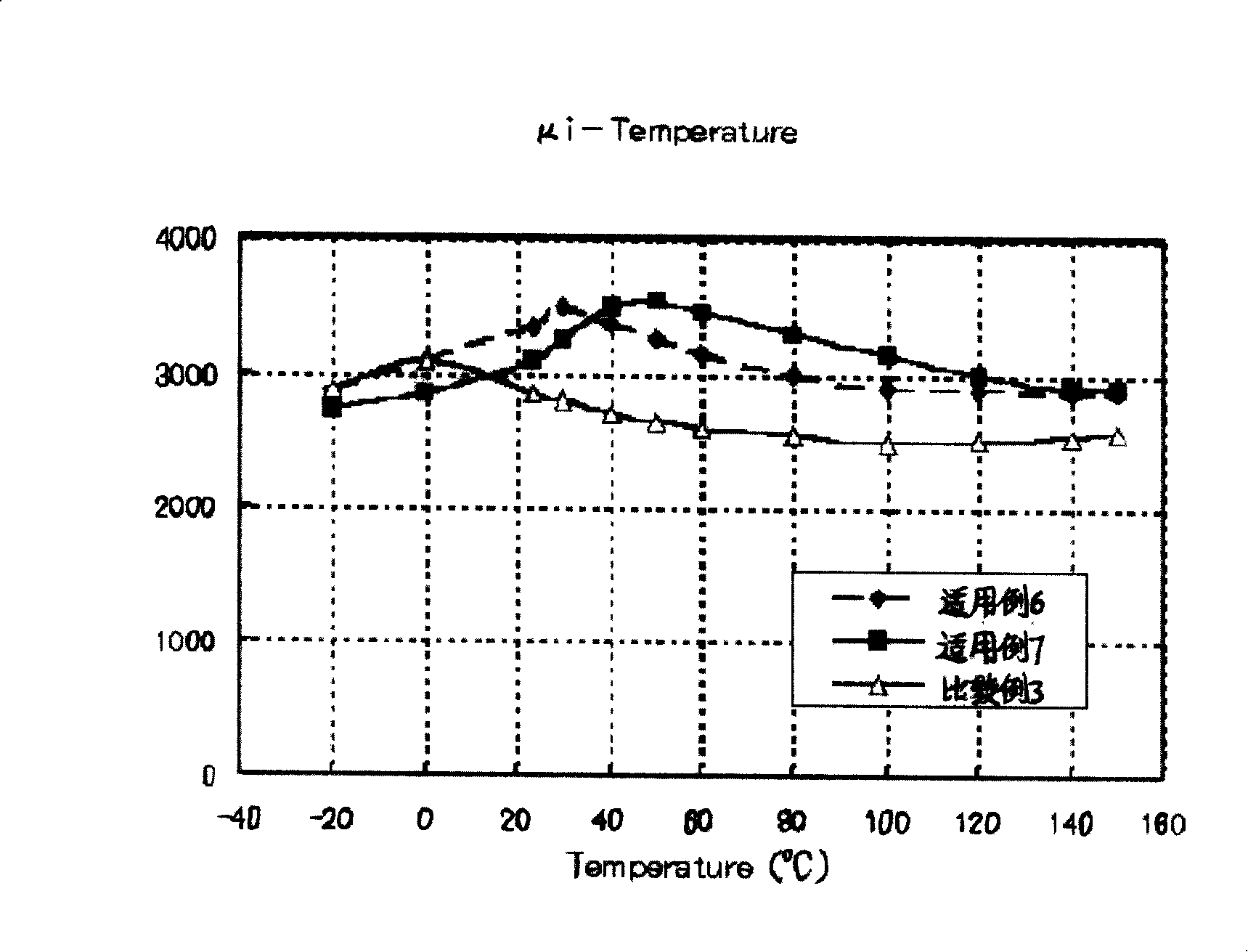

[0035] Use high-purity Fe according to the formula in Table 2 below 2 o 3 , Mn 3 o 4 , ZnO for proportioning, pre-sintering conditions still use a push-type pre-sintering furnace at 950°C for 2 hours for pre-sintering, and also use 20 minutes of crushing;

[0036] Add dopant SiO 2 : 0.005wt%), CaO: 0.04wt%, Nb 2 o5 : 0.02wt% and V 2 o 5 : 0.05wt%, dopant wt% refers to Fe 2 o 3 , Mn 3 o 4 and the total weight ratio of ZnO.

[0037] Also add dopant CoO: 0.3wt%, CoOwt% refers to relative to Fe 2 o 3 , Mn 3 o 4 and the total weight ratio of ZnO.

[0038] Add additives: deionized pure water: 40-50wt%, binder: 0.5-1.5wt%, dispersant: 0.1-0.5wt%, and defoamer: within 0.1wt% and the value is greater than zero; sanding, additives wt% refers to Fe 2 o 3 , Mn 3 o 4 and the total weight ratio of ZnO.

[0039] Use a spray granulation tower to dry and granulate at about 100°C. The obtained raw materials were molded and sintered at 1300°C×5 hours while controlling the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com