Oilfield oil pumping machine energy-saving method and startup wheel

A technology for pumping units and starting wheels, which is applied in earthwork drilling, mechanical equipment, transmission devices, etc., can solve problems such as unsatisfactory power saving effects, achieve the effects of reducing installed capacity, solving starting difficulties, and increasing moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

[0035] 1. Utilize the starting wheel of the present invention to make the small motor also start the pumping unit

[0036] Such as figure 2 The structural representation of the energy-saving friction type starting wheel of the pumping unit of the present invention is shown in the following diagram:

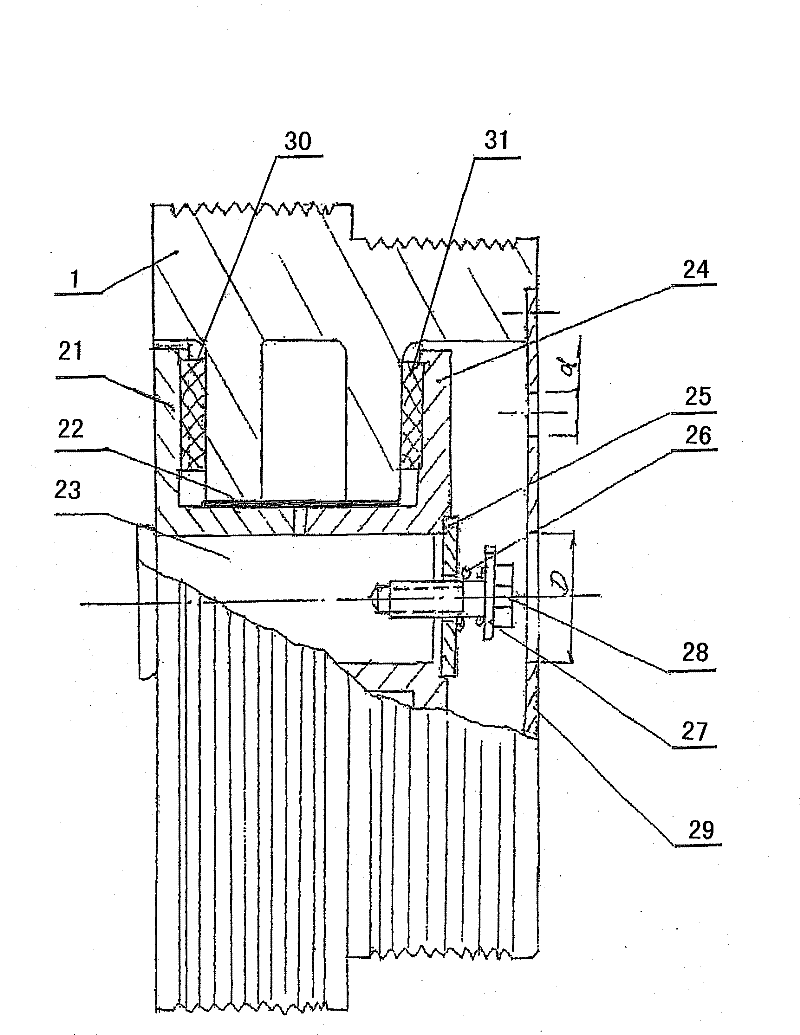

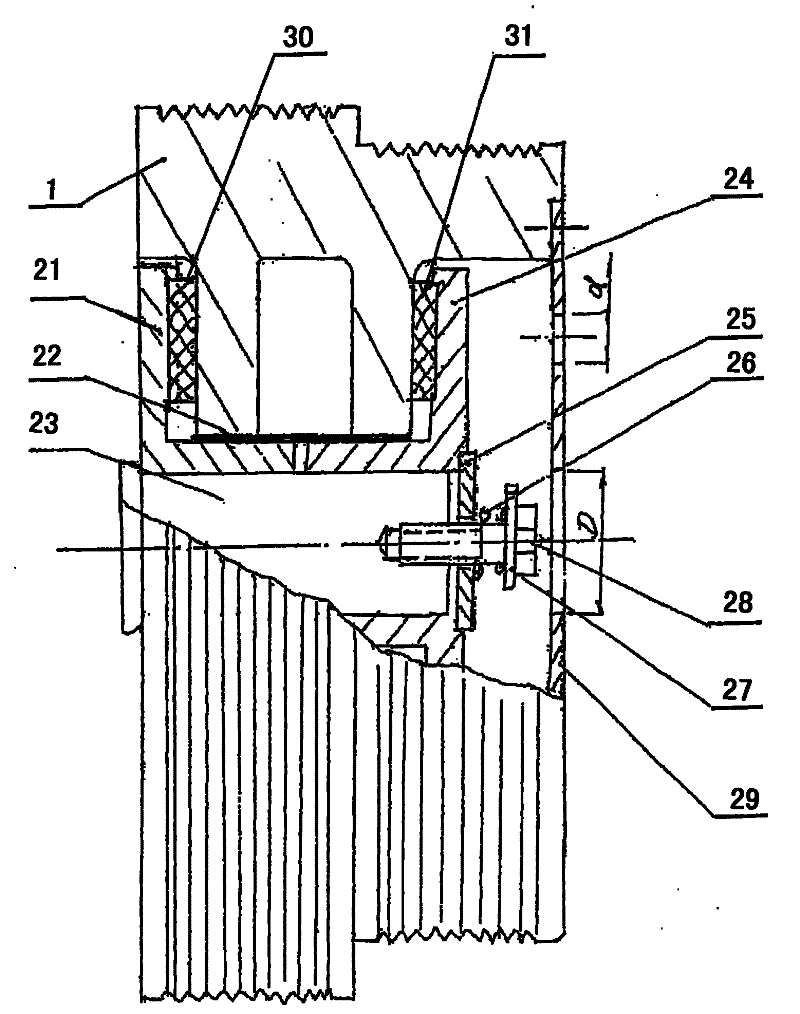

[0037] The adjustable mechanical torque limiting components in the wheel housing 1 include: left friction disc 21, self-lubricating bearing 22, motor shaft 23, right friction disc 24, disc 25, spring 26, nut 27, bolt 28, guard plate 29, The first friction plate 30 and the second friction plate 31 .

[0038] The starting wheel of the present invention is installed on the motor shaft 23, and at the start-up sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com