Low-concentration DMFDMAC saline and acidic wastewater rectifying and recovering device and mechanical application method thereof

A recovery device and low-concentration technology, which is applied in the field of low-concentration DMFDMAC salt- and acid-containing wastewater rectification and recovery devices, can solve the problems of unreachable product quality, tower blockage, and inability to continue production, so as to delay start-up time and avoid blockage The effect of equipment and waste heat utilization on energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

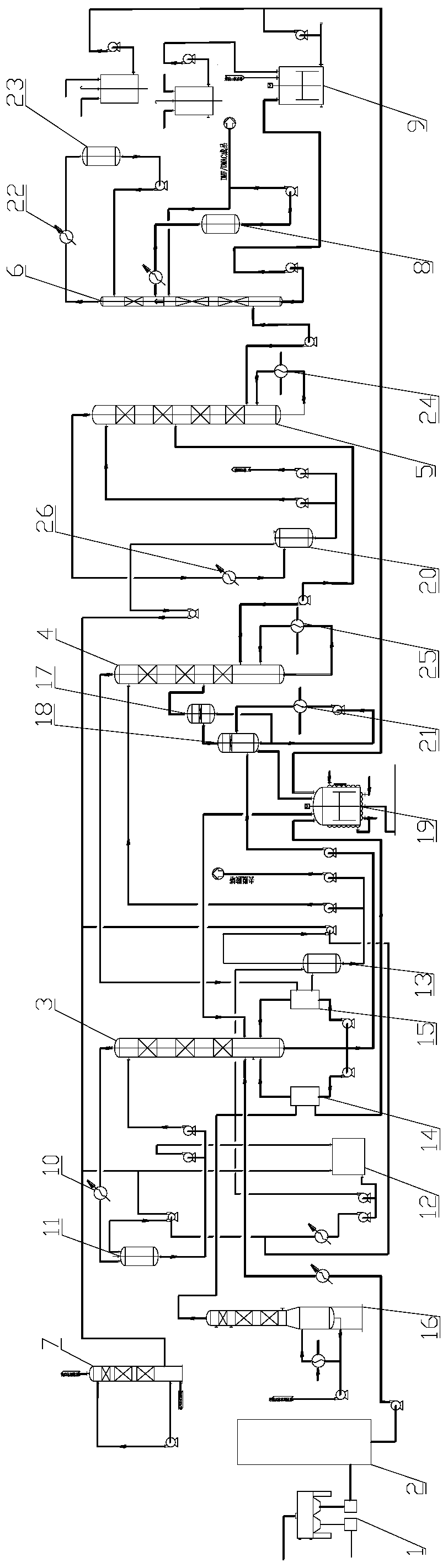

[0025] see figure 1 , in Example 1 of the present invention, a low-concentration DMFDMAC salt-and-acid wastewater rectification recovery device includes a desalination system 1, and the outlet of the desalination system 1 is connected to a liquid storage tank 2, and the liquid storage tank 2 is connected on the primary dehydration tower 3, and the outlet of the primary dehydration tower 3 is connected on the demister device, and the outlet of the demister device is connected on the secondary dehydration tower 4, and the two The outlet of stage dehydration tower 4 is connected on the inlet of rectification tower 5, and the outlet of rectification tower 5 is connected on the inlet of deacidification tower 6, and the side wall of described deacidification tower 6 is provided with finished product Outlet, the finished product outlet is connected to the refined product tank 8, and the outlet end of the refined product tank 8 is respectively connected to the finished product dischar...

Embodiment 2

[0038]In order to process the waste gas in the rectification tower 5, the following settings are made, the top of the rectification tower 5 is connected to the feed inlet of the C tower top liquid storage tank 20 through the B tower top condenser 26, and the C tower top storage tank The outlet of the liquid tank 20 is connected to the rectification tower 5, and the exhaust port on the liquid storage tank 20 at the top of the C tower is connected to the waste gas adsorption tower 7 through a vacuum pump. In addition, the outlet of the liquid storage tank 20 at the top of the C tower is also connected to the liquid storage tank 13 at the top of the B tower.

[0039] The water evaporated from the rectification tower 5 is preheated by the water heater, and then enters the deamination tower 16 to heat and remove the DMA component, and neutralize with dilute acid to crystallize the DMA into salt.

[0040] The rectification tower 5 is provided with a rectification tower reboiler 24 f...

Embodiment 3

[0051] Based on the above-mentioned embodiments, the embodiments of the present invention also disclose a method for rectification and recovery of low-concentration DMFDMAC salt-containing acid-containing wastewater. Specifically, it includes the following steps:

[0052] S1: The low-concentration DMFDMAC salty and acidic waste water is desalinated through the desalination system in turn. The first dehydration tower 3 and the second dehydration tower 4 perform two-stage dehydration, and then pass through the rectification tower 5 for negative pressure rectification, and then enter the Negative pressure deacidification treatment is carried out in the deacidification tower 6;

[0053] S2: After the above treatment is completed, the deacidification tower 6 is discharged from the measuring line, and the discharge of the measuring line is also provided with an upper and lower reflux process;

[0054] S3: The water evaporated from the rectifying tower 5 is preheated by the water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com