Method for producing titanium tetrachloride using low grade titan raw material

A low-grade titanium and titanium tetrachloride technology, applied in the direction of titanium tetrachloride and titanium halide, can solve the problems that large-scale continuous industrial production cannot be realized, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

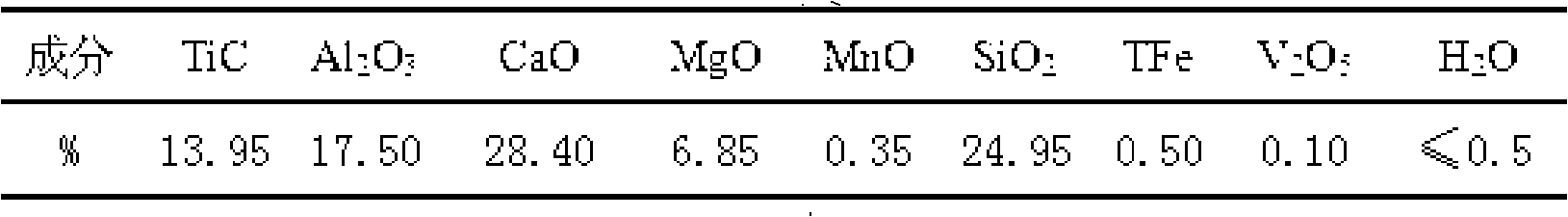

[0032] Embodiment one uses the inventive method to prepare titanium tetrachloride

[0033] Blast furnace slag carbide slag and chlorine gas are used as reaction raw materials, and the diameter of the furnace body is 200mm.

[0034] Add 20kg of fresh carbonized slag and chlorination residue into the chlorination furnace in a ratio of 1:1, heat the charge, and when the temperature of the charge rises to 400°C, start to feed chlorine and air in a ratio of 75%, that is, the amount of chlorine feed is 6m 3 / h, dry air feed rate is 2m 3 / h, the feeding rate of fresh material is 30kg / h, and the amount of residue returning to the furnace is 10kg / h. The solid material residence time is 40min, the temperature is controlled at 640°C±10°C, the system runs stably for more than 8h, the chlorination rate of titanium carbide in the raw material is 91%, and 76kg of crude titanium tetrachloride is collected through the condensation system.

Embodiment 2

[0035] Embodiment two uses the inventive method to prepare titanium tetrachloride

[0036] Blast furnace slag carbide slag and chlorine gas are used as reaction raw materials, and the diameter of the furnace body is 200mm.

[0037] Add 20kg of fresh carbonized slag and chlorination residue into the chlorination furnace in a ratio of 1:1, heat the charge, and when the temperature of the charge rises to 400°C, start to feed chlorine and air in a 50% ratio, that is, the amount of chlorine gas feed is 4m 3 / h, dry air feed rate is 4m 3 / h, the feeding rate of fresh material is 25kg / h, and the amount of residue returning to the furnace is 15kg / h. The solid material residence time is 28min, the temperature is controlled at 610°C±10°C, the system runs stably for more than 8h, the chlorination rate of titanium carbide in the raw material is 86%, and 63kg of crude titanium tetrachloride is collected through the condensation system.

Embodiment 3

[0038] Embodiment three uses the inventive method to prepare titanium tetrachloride

[0039] Blast furnace slag carbide slag and chlorine gas are used as reaction raw materials, and the diameter of the furnace body is 200mm.

[0040] Add 20kg of fresh carbonized slag and chlorination residue into the chlorination furnace at a ratio of 1:1, heat the charge, and when the temperature of the charge rises to 400°C, feed pure chlorine gas with a flow rate of 6m 3 / h, the feeding rate of fresh material is 35kg / h, and the amount of residue returning to the furnace is 5kg / h. The solid material residence time is 42min, the temperature is controlled at 610°C±10°C, the system runs stably for more than 8h, the chlorination rate of titanium carbide in the raw material is 84%, and 88kg of crude titanium tetrachloride is collected through the condensation system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com