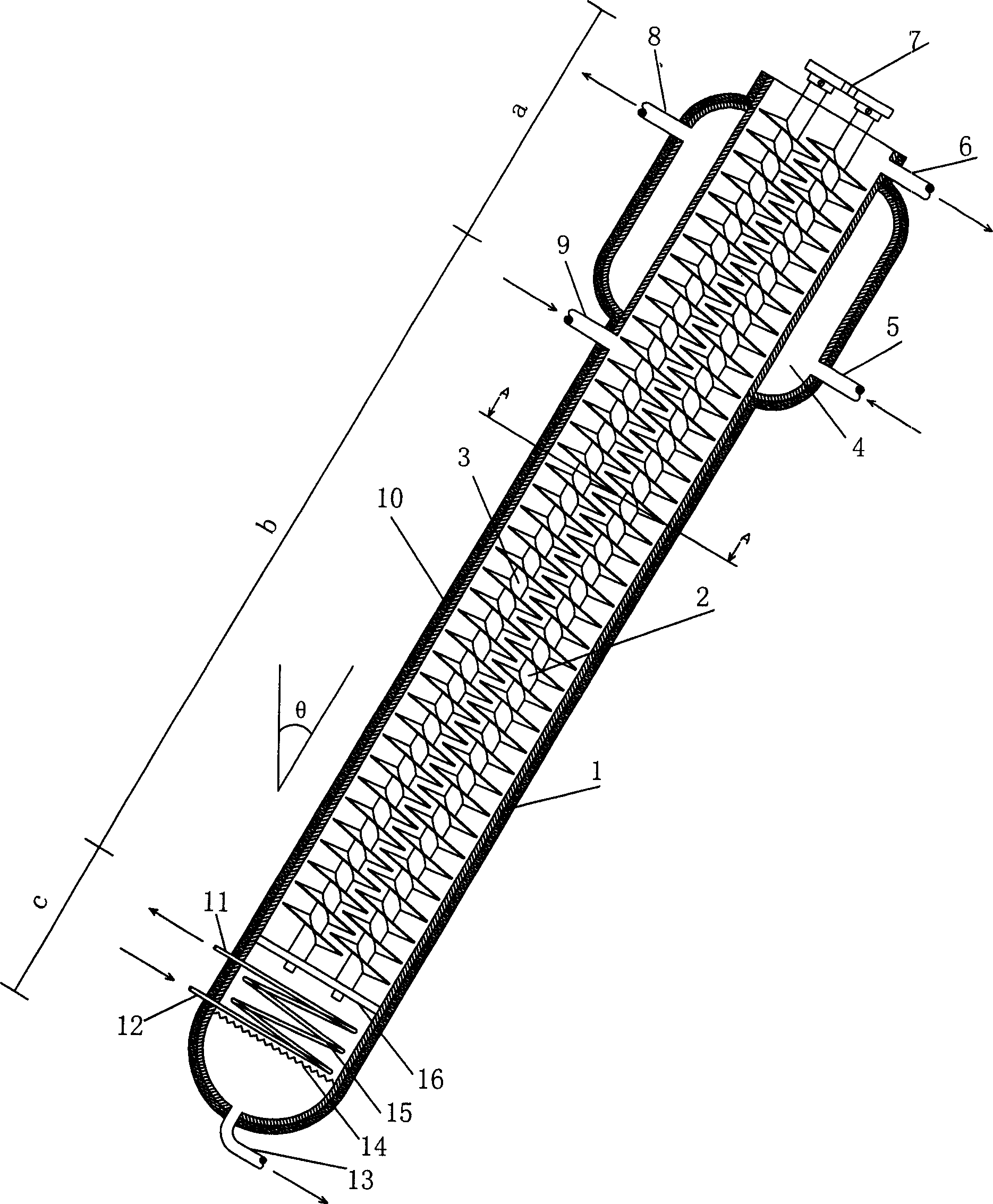

Equipment for preparing high pure organic matter by fusion-crystallization method

A technology for melt crystallization and organic matter, which is applied in the field of devices for preparing high-purity organic matter, can solve the problems of low purification effect, failure to achieve washing effect, and increased energy consumption, so as to improve separation and purification effect, improve stable countercurrent flow, and power consumption. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Purification of mixed dichlorobenzene multi-component deep eutectic system

[0033] High-purity p-dichlorobenzene is a fine chemical product and an important raw material for organic synthesis, usually obtained by directional chlorination of benzene. In this example, the percentage by weight of p-dichlorobenzene in the mixed dichlorobenzene coarse crystals obtained by directional chlorination of benzene is 65%, and the rest is o-dichlorobenzene and m-dichlorobenzene, which need further purification. The components of mixed dichlorobenzene coarse crystals are isomers, and their physical properties are shown in Table 1:

[0034] Melting point °C

p-dichlorobenzene

53.09

174

m-dichlorobenzene

-24.8

173

o-dichlorobenzene

-17

180

[0035] It can be seen from Table 1 that the boiling points of the components in the coarse crystals of mixed dichlorobenzene are very close...

Embodiment 2

[0038] Embodiment 2: the purification of acrylic acid-propionic acid two-component solid solution type system

[0039] Acrylic acid is an important organic chemical raw material and an important synthetic resin monomer. Synthetic acrylic acid often contains a small amount of by-product propionic acid. To prepare high-purity acrylic acid, it is necessary to separate a small amount of propionic acid in the product. In the acrylic acid-propionic acid mixture of this embodiment, the weight percentage of acrylic acid is 70%. The physical properties of acrylic acid-propionic acid are shown in Table 2:

[0040] Melting point °C

propionic acid

-20.5

141.15

acrylic

12.5

141

[0041] It can be seen from Table 2 that the boiling points of acrylic acid and propionic acid are basically the same, but the melting point is quite different. In addition, acrylic acid is a heat-sensitive substance, which can undergo p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com