Transport device in a facility for processing substrates

A technology for transporting devices and processing substrates, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as interference sources, and achieve high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

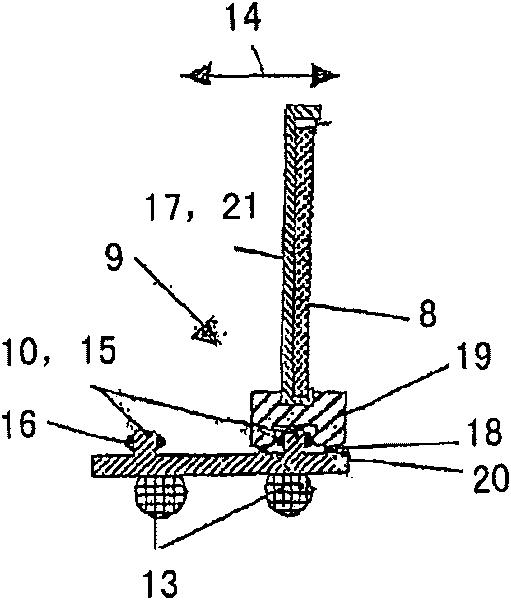

[0056] exist figure 1 The vertical in-line coating apparatus according to embodiment A comprises two adjacent coating stations 1 and two adjacent lock chambers 2, wherein the coating stations 1 and the lock chambers 2 are separated from each other by a vacuum-tight chamber valve 3 open. The transport device according to the invention passes through the lock chamber 2 and the coating station 1 , said device being formed by several transport segments 5 arranged in succession along the transport line 4 . The transport section 5 according to embodiment A is formed for transporting substantially vertically aligned flat substrates 8, wherein, in particular, figure 1 The transport sections 5 in are parts of an air cushion transport device, wherein each transport section 5 has an inclined or substantially vertically oriented substrate guide plate 6, and transport rollers 7 are arranged at the base (from Figure 2a As can be easily seen in ), by means of the transport rollers 7, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com