Method for processing acid-containing hydrocarbon oils

A hydrocarbon oil and high-acid technology, which is applied in the direction of refining to remove heteroatoms, etc., can solve problems such as difficulty in ensuring long-term operation, easy blockage of catalyst channels, and fouling on the top of the reactor, so as to slow down the problem of orifice blockage and reduce Effect of processing cost and reducing processing severity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

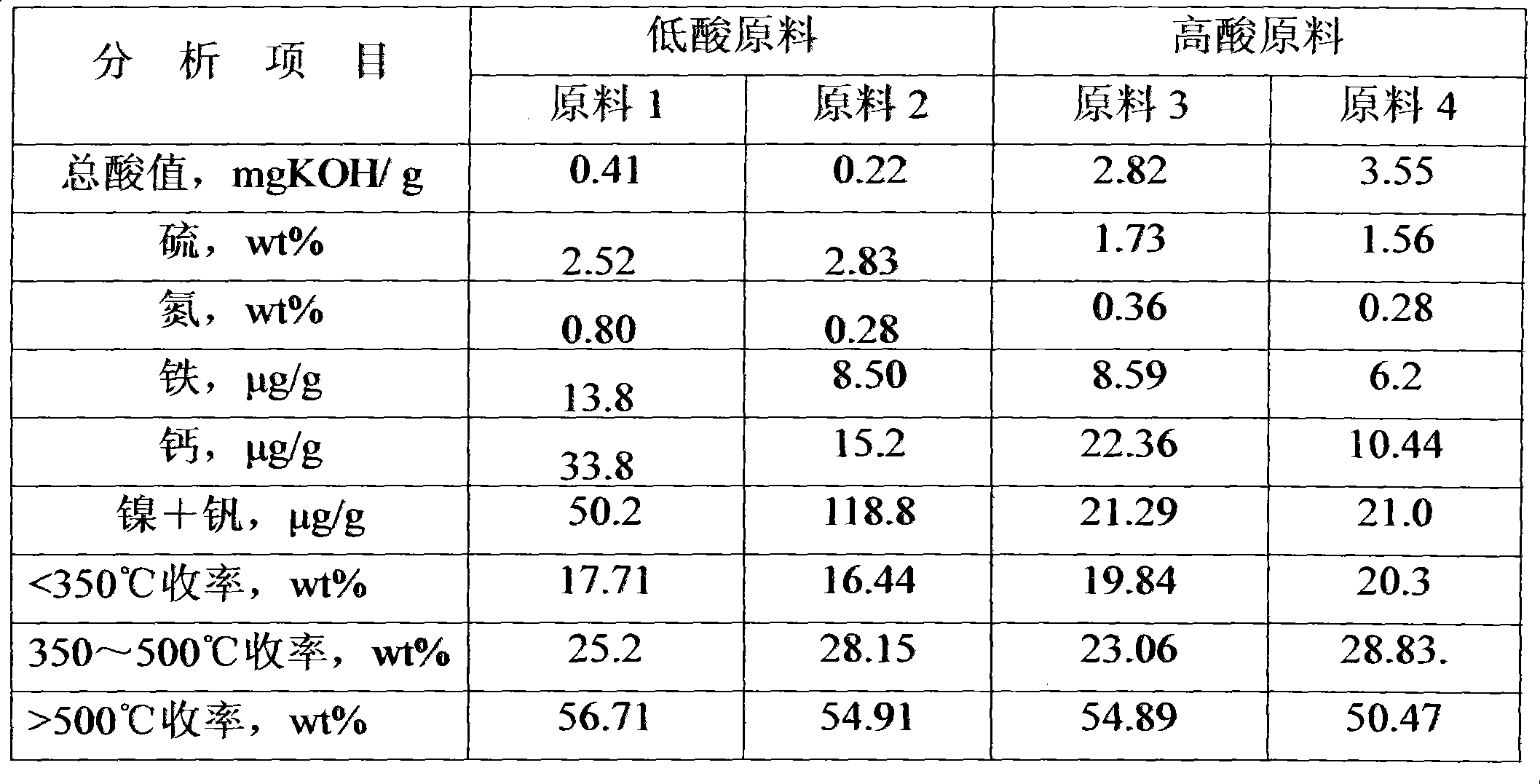

[0032] The low-acid raw material and the high-acid raw material are heated to the required temperature and then mixed into the fixed-bed hydrogenation reactor. In the presence of hydrogen, they are contacted with a hydrogenation catalyst for hydrogenation treatment. The raw material properties are shown in Table 1, the hydrogenation catalyst used is shown in Table 2 and Table 3, the operating conditions used in the examples are shown in Table 4, and the reaction results are shown in Table 5.

[0033] Table 1 Properties of Raw Materials

[0034]

[0035] The nature of the large-pore hydrogenation protection catalyst used in the embodiment of table 2

[0036]

Catalyst A

Catalyst B

metal composition

CoO, wt%

1.0

—

NiO, wt%

3.0

2.5

MoO 3 , wt%

2.0

5.0

WO 3 , wt%

—

0.5

nature

Specific surface, m 2 / g

136

150

Pore volume, ml / g

0.74

0.62

Pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com