Method for preparing propylene catalyst from methanol conversion

A technology for methanol conversion and catalyst, which can be used in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., and can solve problems such as low propylene yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

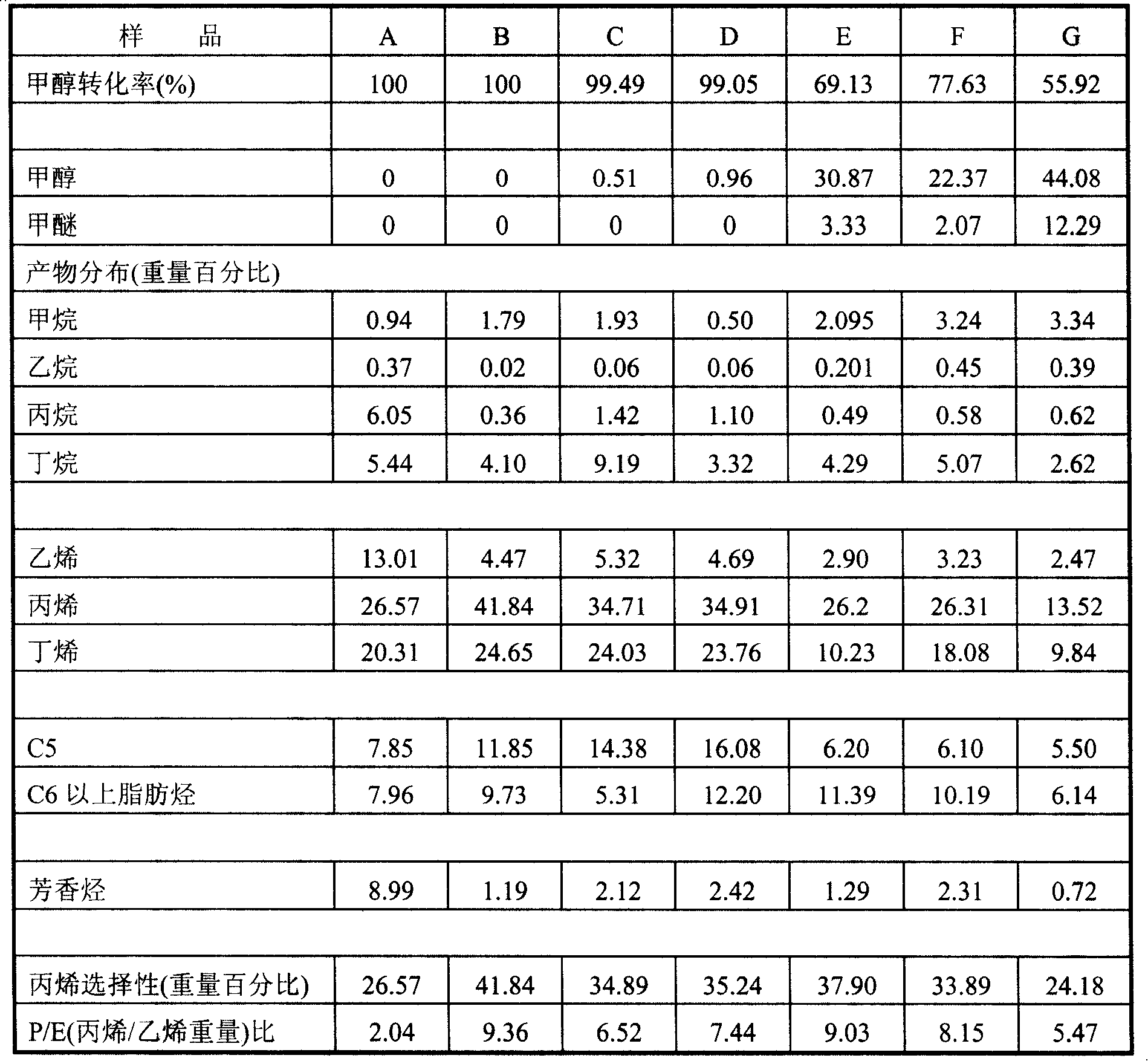

Embodiment 1

[0021] The ZSM-5 prepared by Comparative Example 1 was roasted at 500°C for 7 hours, and then exchanged with 1 mol / liter of hydrochloric acid solution. The exchange temperature was 90°C and the time was 5 hours. The sodium solution is subjected to alkali treatment, the treatment time is 16 hours, and the solid-to-liquid ratio is 1 / 10 (g / g). After washing and drying, it is exchanged twice with 1 mol / L hydrochloric acid solution at 90°C for two hours each time. Sample B was obtained by washing, drying and calcining at 550° C. for 5 hours. Under the same reaction conditions as in Example 1, its product distribution is shown in Table 1.

Embodiment 2

[0023]The ZSM-5 prepared by Comparative Example 1 was roasted at 450°C for 5 hours, and then exchanged with a 6 mol / liter hydrochloric acid solution. The exchange temperature was 90°C and the time was 5 hours. The sodium solution is subjected to alkali treatment, the treatment time is 8 hours, and the solid-to-liquid ratio is 1 / 20 (g / g). After washing and drying, it is exchanged twice with 1 mol / L hydrochloric acid solution at 90°C for two hours each time. Sample C was obtained by washing, drying and calcining at 500° C. for 6 hours. Under the same reaction conditions as in Example 1, its product distribution is shown in Table 1.

Embodiment 4

[0025] The ZSM-5 prepared by Comparative Example 1 was roasted at 300°C for 24 hours, and then exchanged with a 2 mol / liter phosphoric acid solution. The exchange temperature was 30°C and the time was 9 hours. The sodium solution is subjected to alkali treatment, the treatment time is 24 hours, and the solid-to-liquid ratio is 1 / 10 (g / g). After washing and drying, it is exchanged twice with 3 mol / L phosphoric acid solution at 90° C. for two hours each time. Sample D was obtained by washing, drying and calcining at 350° C. for 16 hours. Under the same reaction conditions as in Example 1, its product distribution is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com