Blower fan integral wheel and method of manufacture

A technology of integral impeller and manufacturing method, which is applied in the direction of manufacturing tools, mechanical equipment, casting and molding equipment, etc., can solve problems such as installation angle measurement error, fan fan strength decrease, and inability to process integral impeller, so as to achieve rated efficiency improvement and operating efficiency Improvement and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the utility model is further described.

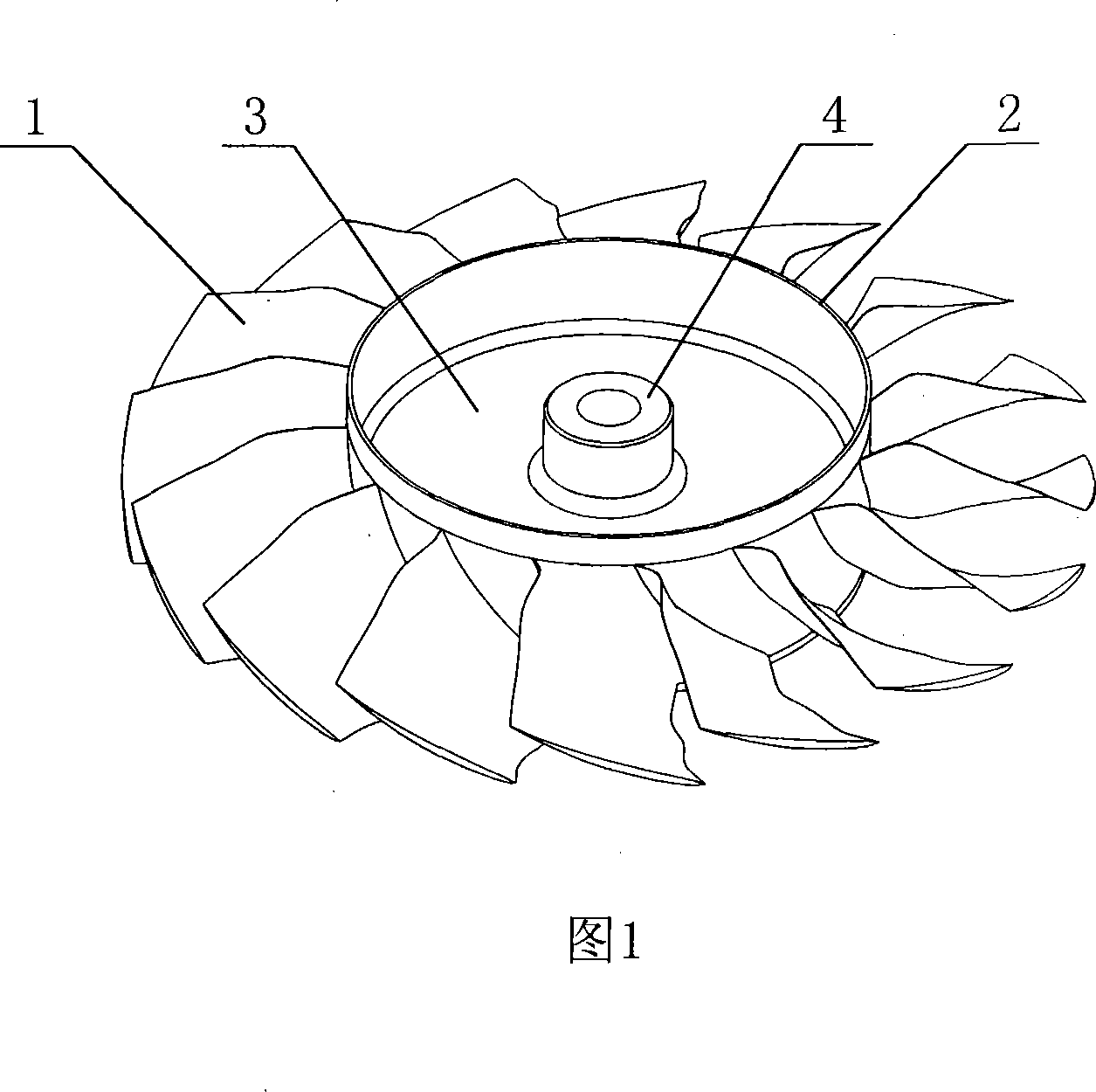

[0025] Referring to Fig. 1 , a fan integral impeller includes blade 1, hub 2, spoke 3, and bearing sleeve 4, and the blade 1, hub 2, spoke 3, and bearing sleeve 4 are integrally formed by one-time casting. Any one of the blades of the impeller and its adjacent blades have overlapping projections along the axial direction of the impeller. The blade 1 is a combination of curved and swept orthogonal three-dimensional twisted blades. .

[0026] The manufacturing method of the integral impeller of the above-mentioned blower fan, its steps are as follows:

[0027] (1) Make a mould, the cavity shape of which is a curved and swept combination orthogonal three-dimensional twisted integral impeller;

[0028] (2) Inject wax into the cavity through the gate of the mold;

[0029] (3) After the wax in the mold cavity is solidified, demoulding is carried out. The specific method is to lift whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com