Method for preparing carbon nano-tube modified polyaniline nano fiber composite material

A carbon nanotube modification and nanofiber technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, can solve the problems of reduced electrochemical performance of composite materials, and achieve excellent electrochemical performance, high conductivity, large Surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Put a certain amount of multi-walled carbon nanotubes into 98% concentrated H 2 SO 4 and 63% concentrated HNO 3 (volume ratio: H 2 SO 4 : HNO 3 =3:1) in a mixed acid, heated at 60° C. for 6 hours, then repeatedly washed with deionized water until neutral, and dried to obtain acid-treated multi-walled carbon nanotubes. Weigh 0.14g of acid-treated multi-walled carbon nanotubes and add them to 100mL of 1.5mol / L perchloric acid aqueous solution, ultrasonically disperse for 2 hours; then add 4.47g (48mmol) of aniline monomer into the above mixing system, stir and mix for 0.5 Hour. Then weigh 2.75g (12mmol) ammonium persulfate and dissolve it in 50mL of 1.5mol / L perchloric acid aqueous solution, slowly add the ammonium persulfate solution dropwise to the above solution, and stir and react at room temperature for 24 hours. The product is filtered, washed and dried to obtain a doped polyaniline / multi-walled carbon nanotube composite material. The above-mentioned doped st...

Embodiment 2

[0032]The process of Example 1 was repeated to prepare acid-treated multi-walled carbon nanotubes. Weigh 0.75g of acid-treated multi-walled carbon nanotubes into 50mL of 1mol / L perchloric acid aqueous solution, and ultrasonically disperse for 4 hours; then add 4.47g (48mmol) of aniline monomer into the above mixing system, and stir and mix for 1 hour . Then weigh 5.5g (24mmol) of ammonium persulfate and dissolve it in 50mL of 1mol / L perchloric acid solution, slowly add the ammonium persulfate solution dropwise to the above solution, and stir and react at room temperature for 12 hours. The product is filtered, washed and dried to obtain a doped polyaniline / multi-walled carbon nanotube composite material. The above-mentioned doped state polymerization product was dispersed in 10 wt% ammonia water and stirred for 24 hours to obtain a dedoped multi-walled carbon nanotube-modified polyaniline composite material.

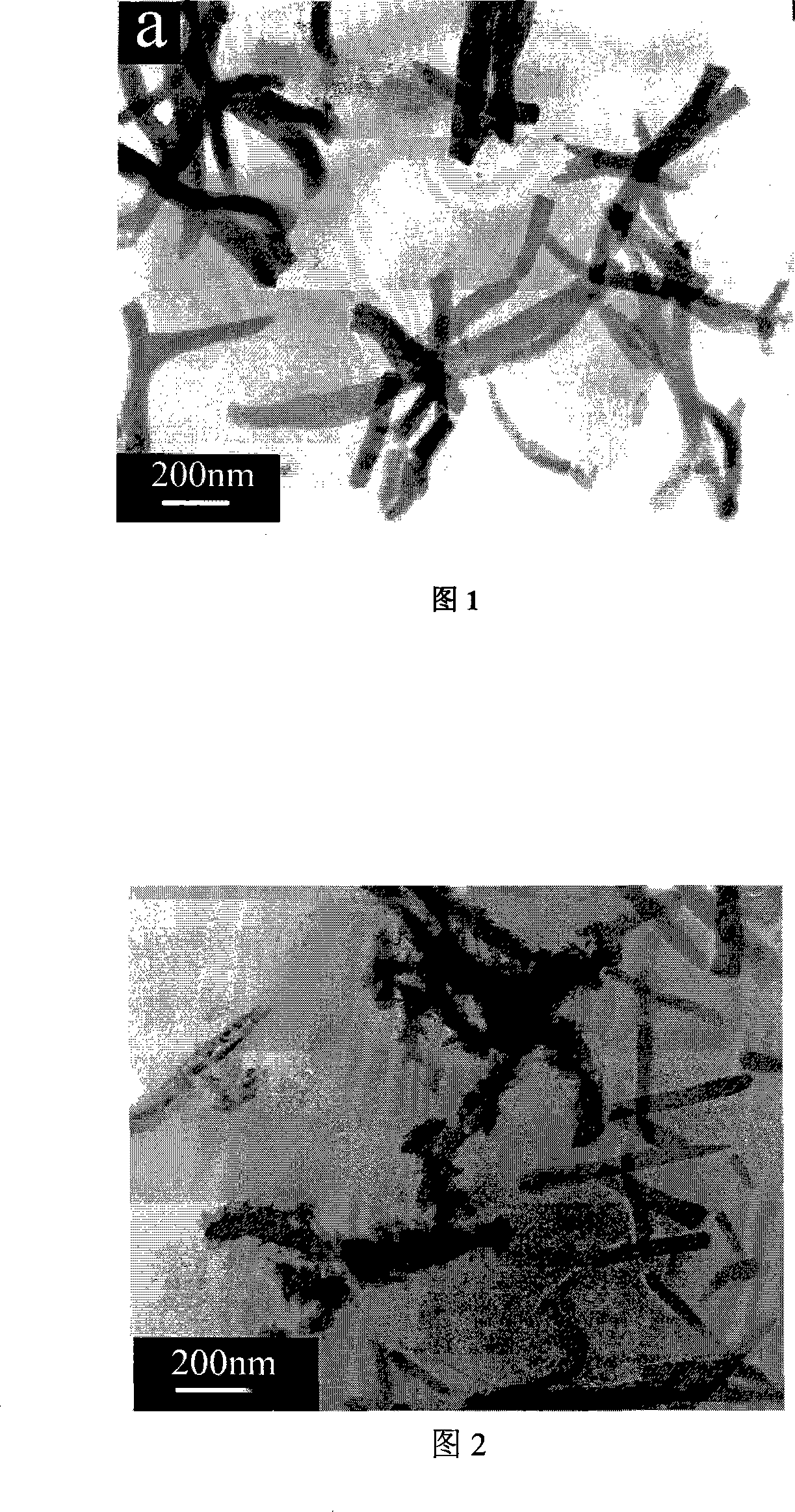

[0033] Transmission electron micrographs show that the polyaniline...

Embodiment 3

[0036] Repeat the process of Example 1, with 69% concentrated HNO 3 Instead of 63% concentrated HNO 3 , the treatment time is 24h, and acid-treated multi-walled carbon nanotubes are prepared. Weigh 0.28g of acid-treated multi-walled carbon nanotubes into 100mL of 3mol / L perchloric acid aqueous solution, and ultrasonically disperse for 1 hour; then add 4.47g (48mmol) of aniline monomer into the above mixing system, and stir and mix for 1 hour . Then weigh 1.38g (6mmol) ammonium persulfate and dissolve it in 30mL of 3mol / L perchloric acid solution, slowly add the ammonium persulfate solution dropwise to the above solution, and stir and react at room temperature for 48 hours. Finally, the product is filtered, washed and dried to obtain the doped multi-walled carbon nanotube modified polyaniline composite material.

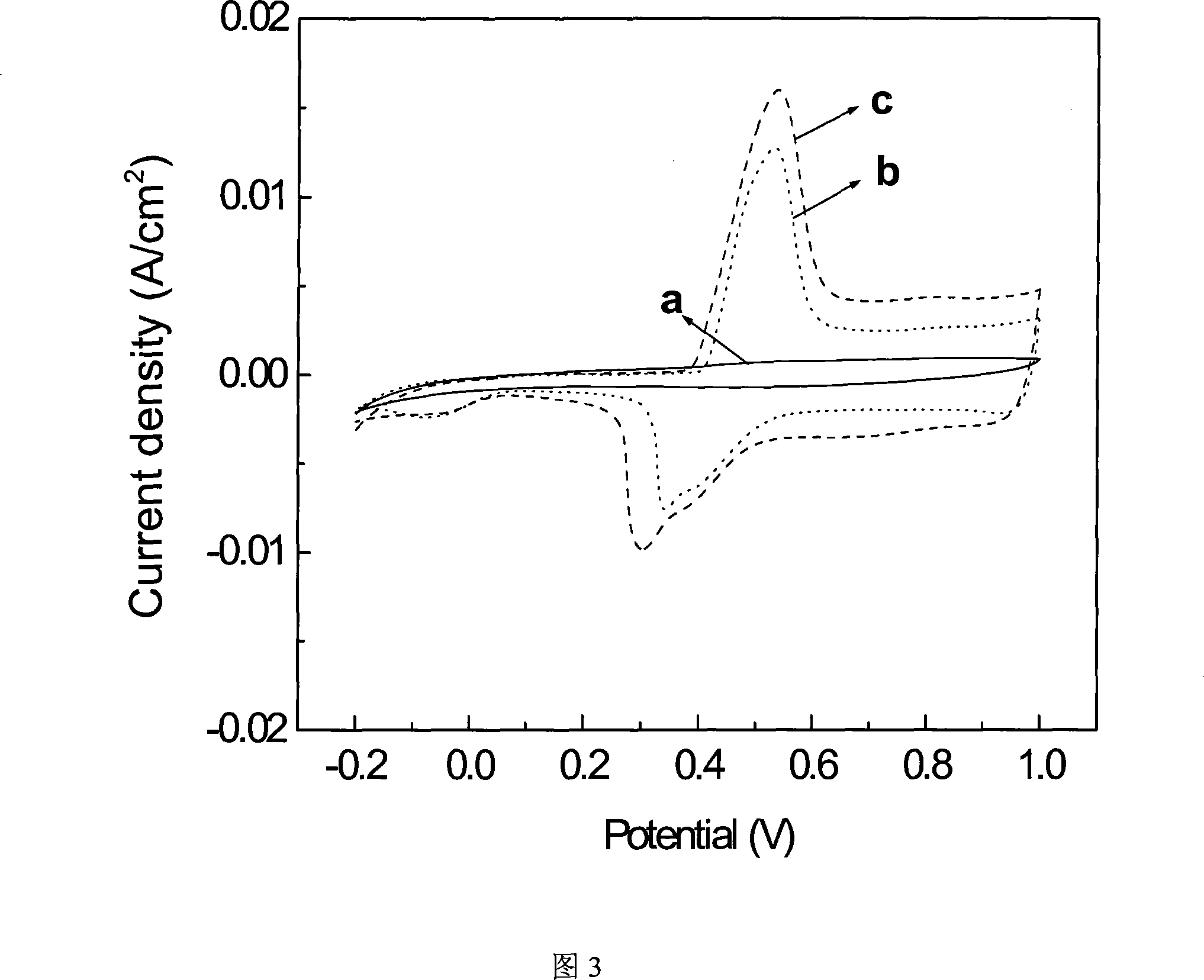

[0037] Transmission electron micrographs show that the polyaniline composite material modified by multi-walled carbon nanotubes presents a structure in which polya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com