Steady flow distribution device for dual-roller thin band continuous casting

A twin-roll thin strip continuous casting and steady flow technology, which is applied in the field of steady flow distribution devices, can solve problems such as increased fluctuations in the molten pool liquid level, abnormal continuous casting process, and unstable molten steel flow, so as to avoid the impact of streams force, stable flow state, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

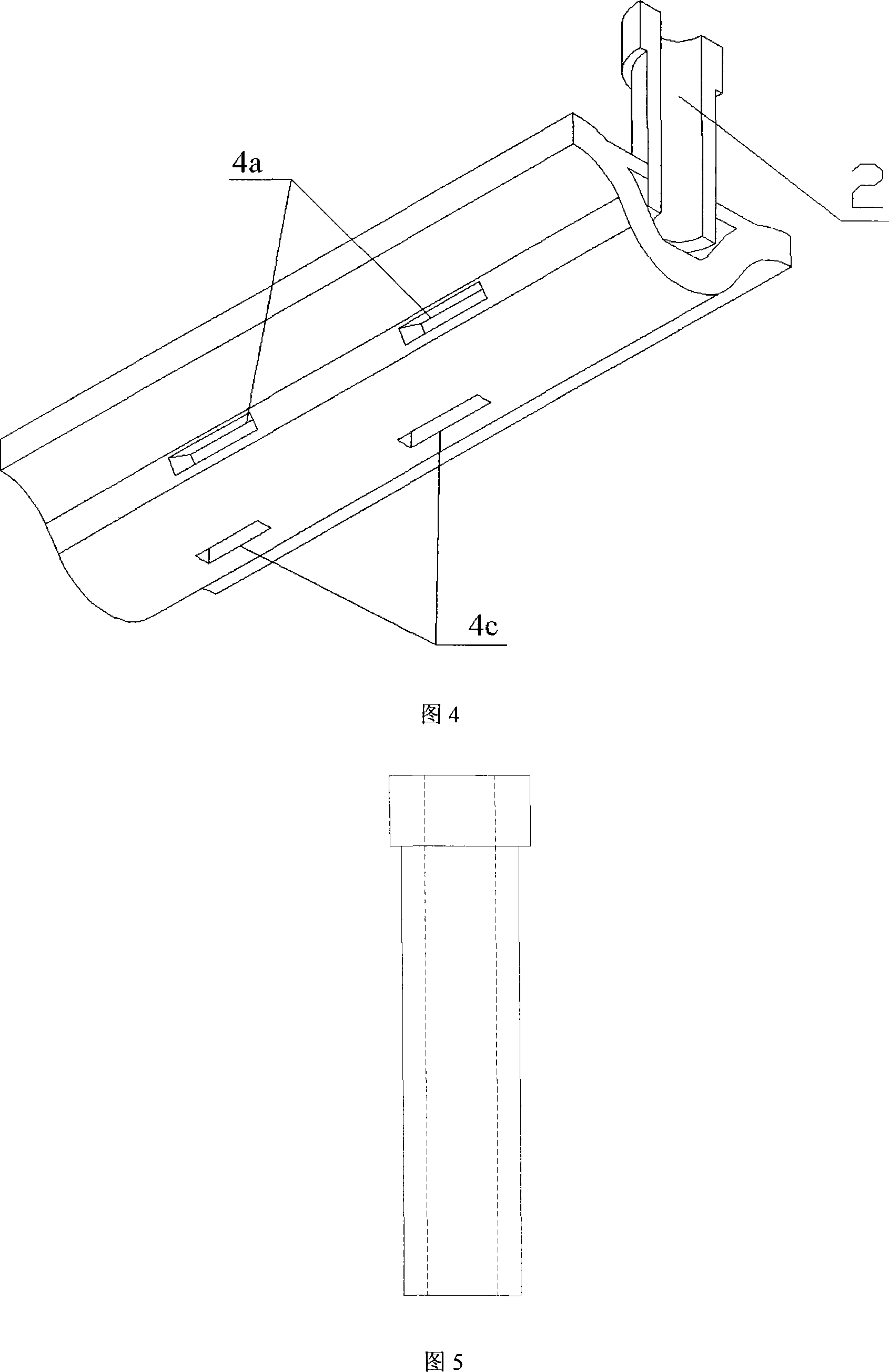

[0013] Embodiment 1: Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, the steady flow distribution device for twin-roll thin strip continuous casting in this embodiment mainly includes a flow distributor 1 provided with flow distribution holes 4 , Submerged nozzle 2, these parts devices are basically the same as those traditionally used in the past. In the present invention, the overall appearance of the flow distributor 1 is boat-shaped, which is immersed in the molten steel in the molten pool, and its cross-section is a "V" shape with a circular arc at the bottom. There are multiple flow distribution devices on the whole. The hole 4 includes a circular distribution hole 4b starting at both ends, a distribution hole 4a on the curved surface on both sides and a distribution hole 4c starting at the bottom; the inside of the distributor 1 is empty. The cavity is provided with a cover plate 8 on its top surface, and a rectangular opening slot 7 is opened on the cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com