Long guide roller outlet table for tube rolling machine

A technology of long guide rollers and guide rollers, which is used in guiding/positioning/aligning devices, metal rolling, metal rolling, etc., can solve the problems of large weight and motor power of export table equipment and the difficulty of rolling large-diameter high-strength steel pipes , the diameter of the waste pipe should not be too large, etc., to achieve the effect of expanding the motor power and reducer volume, compact structure, and improving the quality of the waste pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

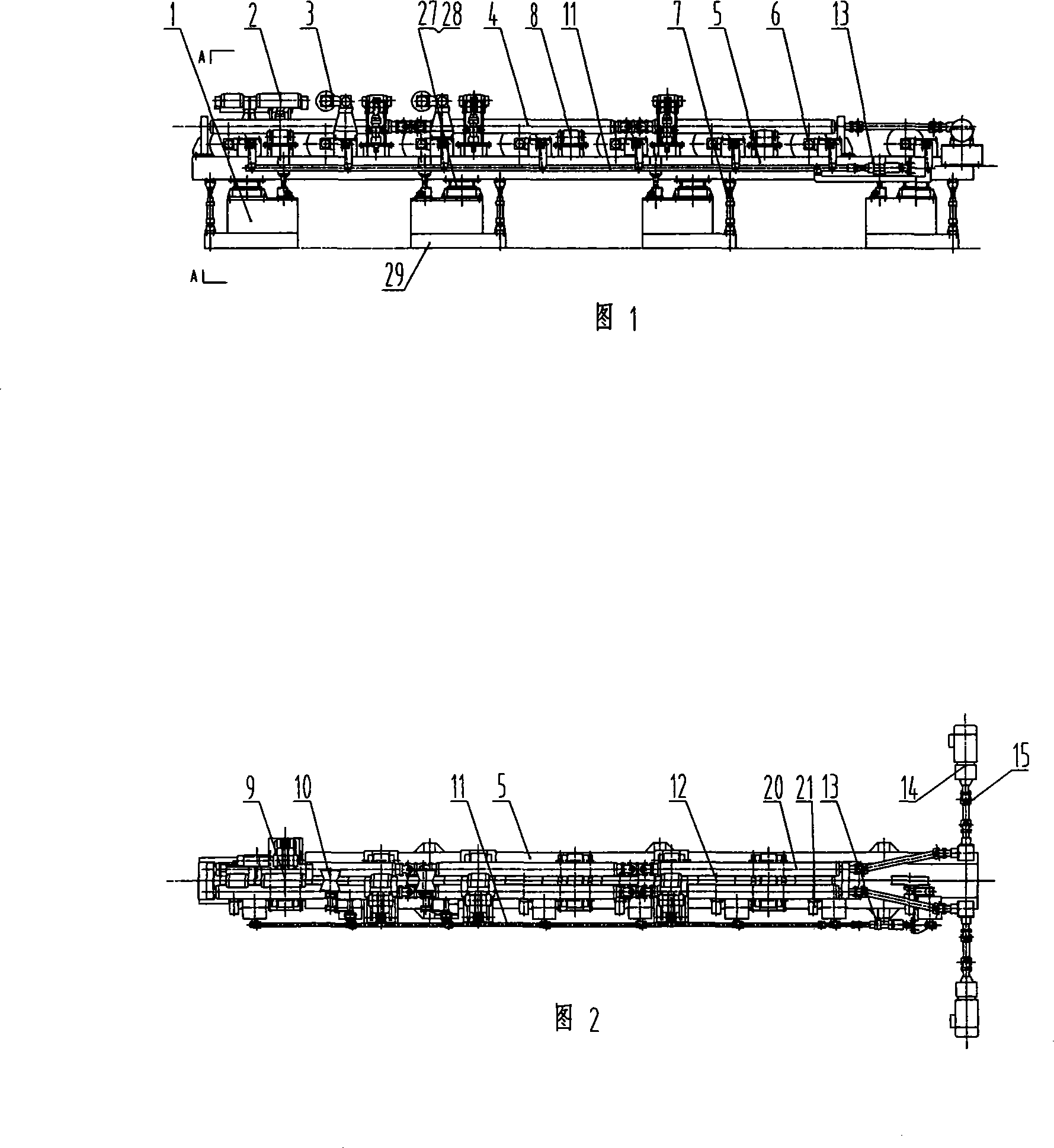

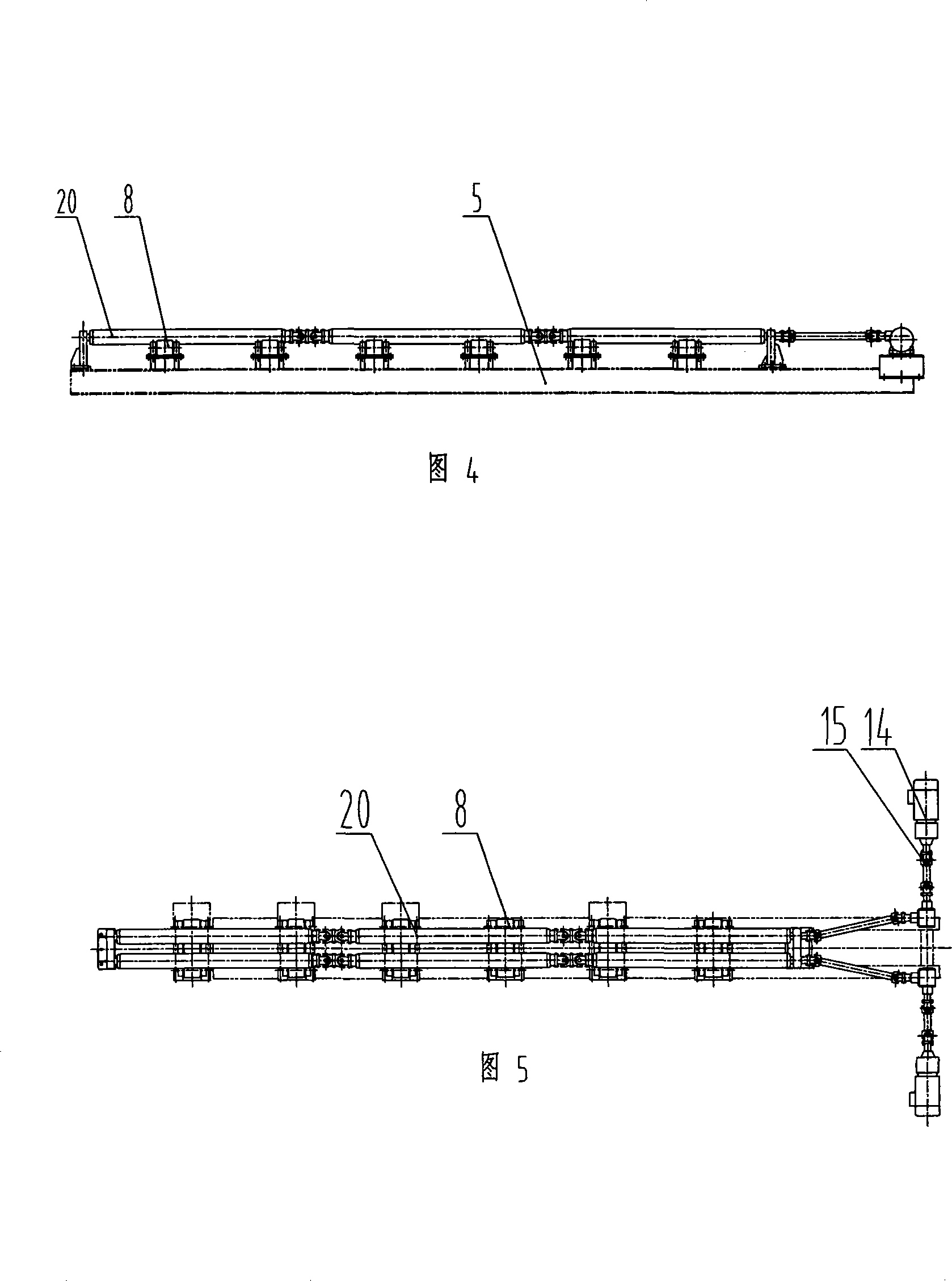

[0019] As shown in Figures 1, 2, 3, 4, and 5, a long guide roll exit table for a pipe mill is composed of a lifting base device 1, an upper pressing roll device 2, a V-shaped pressing roll device 3, two The long guide roller device 4 of the group belt transmission, the elevating beam 5, and the elevating transmission roller table device 6 are formed. The lower part of the lifting beam 5 is equipped with a lifting base device 1, and the upper part is equipped with a long guide roller device 4 driven by a transmission motor 14 with a support roller 8, an upper pressure roller device 2 and a V-shaped pressure roller device 3, two long guide rollers In the middle of 20, there is a lifting transmission roller table device 6.

[0020] Lifting base device 1 is equipped with on its base 29 upper sliding seat 27, lower seat 28, locking hydraulic cylinder 7, and the screw jack 17 driven by lifting motor 16. Two transmission motors 14 respectively drive two long guide rollers 20 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com