Self-cleaning sewage treating device

A sewage treatment device and self-cleaning technology, applied in water/sewage treatment, water/sludge/sewage treatment, gravity filter, etc., can solve the problems that metal filter nets are easy to be corroded, accelerated mesh channel blockage, corrosion, etc. , to achieve high sewage filtration efficiency, increase flow channel density, and increase working strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

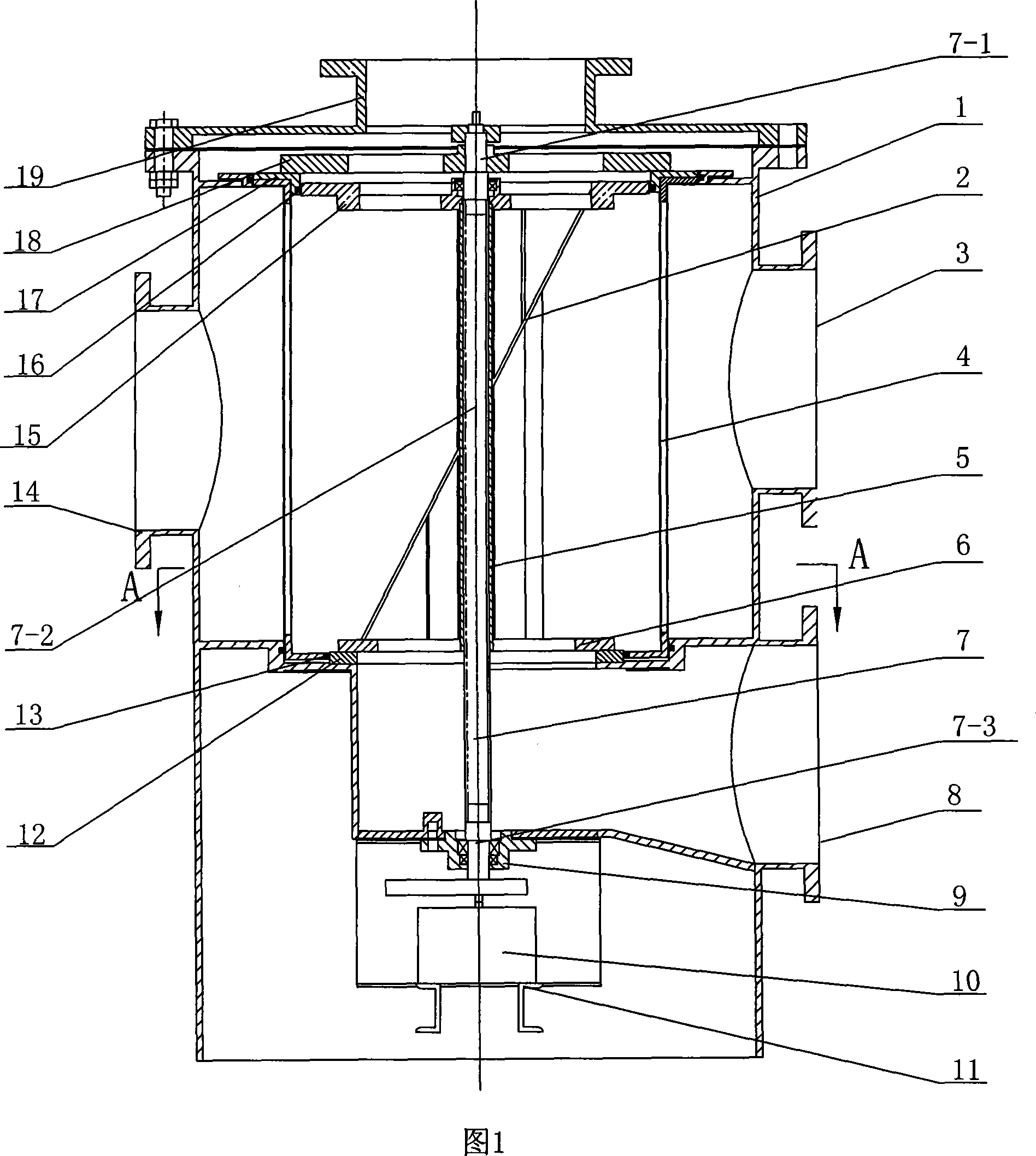

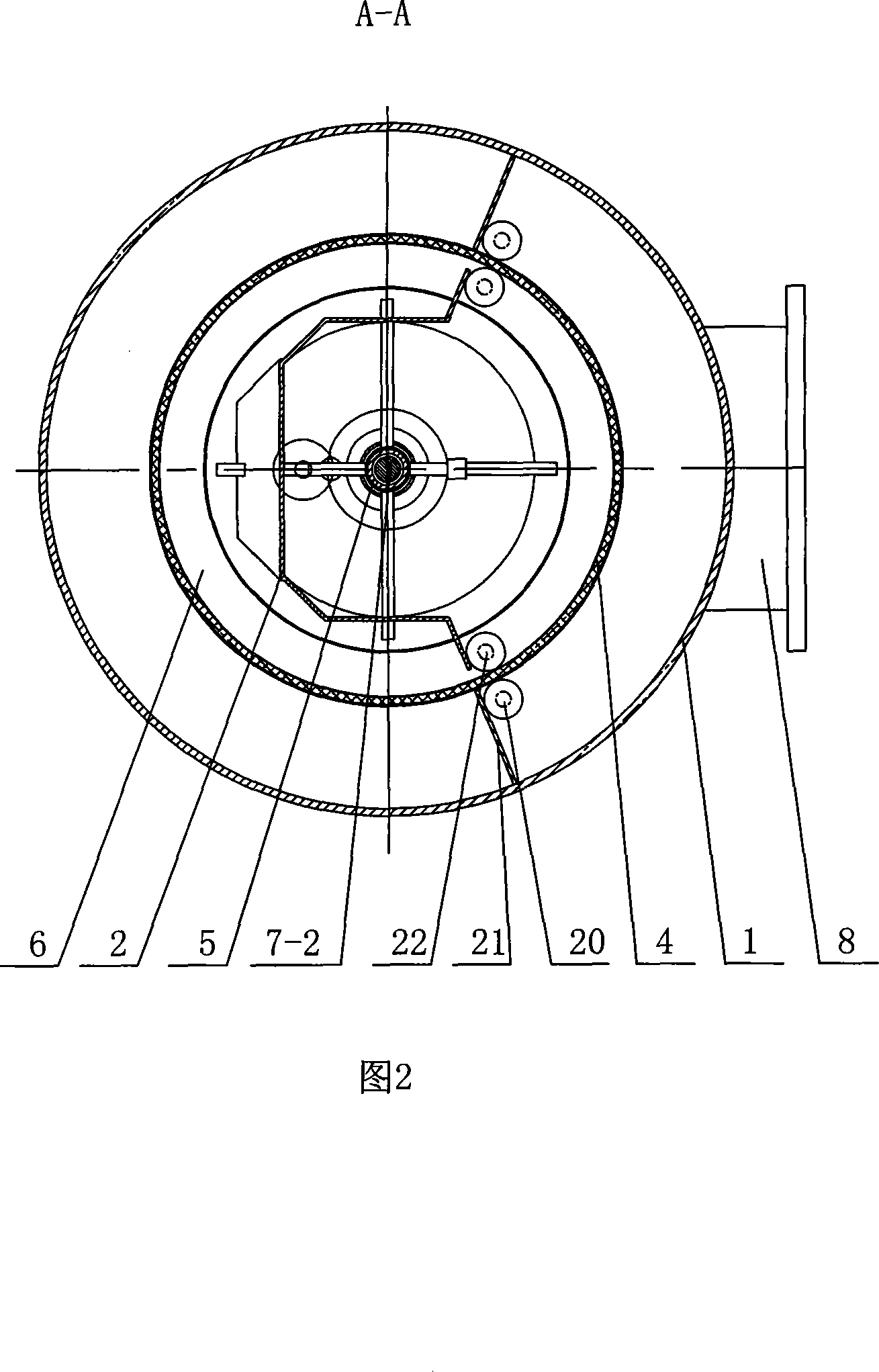

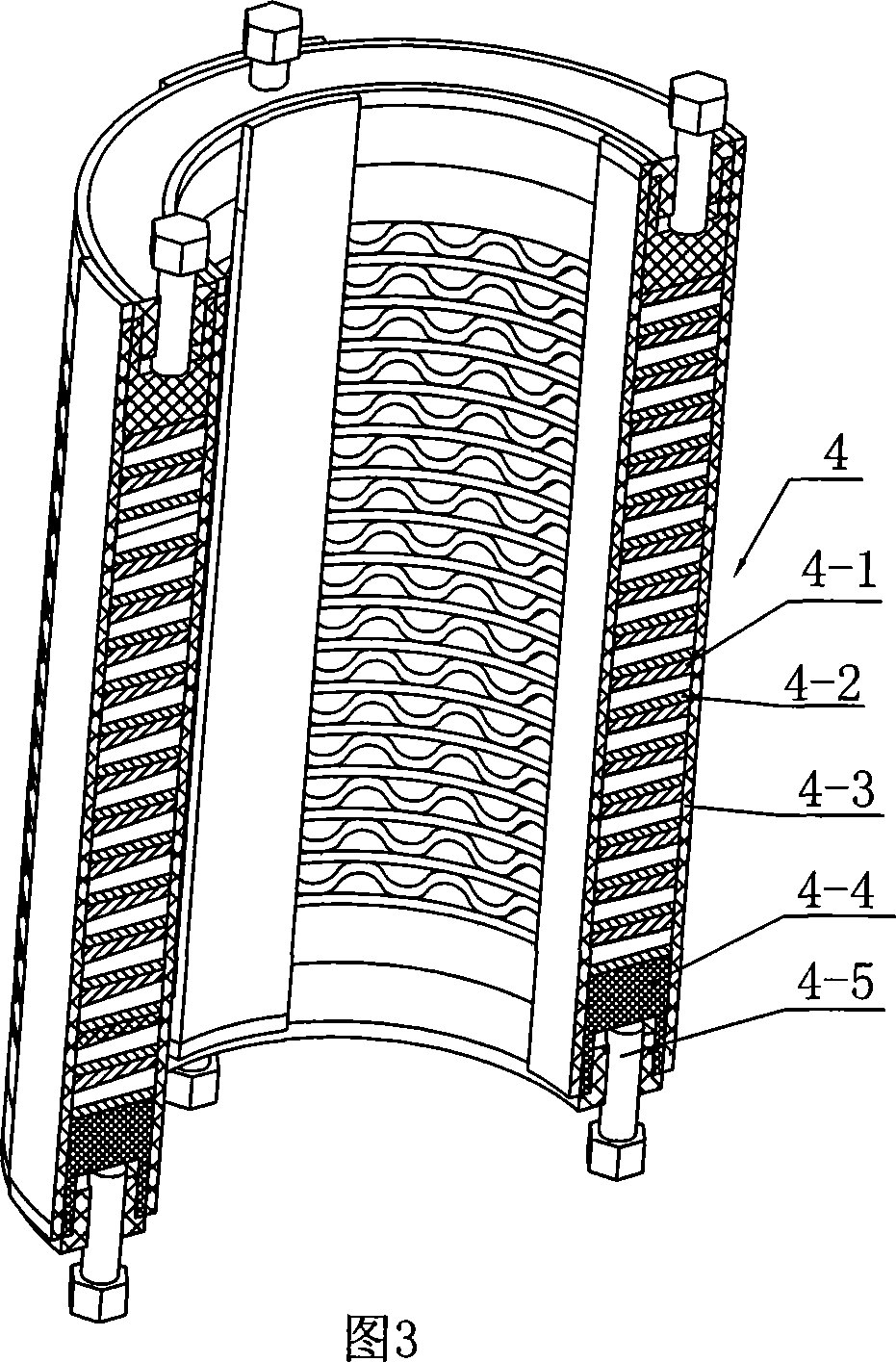

[0013] The self-cleaning sewage treatment device of the present invention shown in FIG. 1 includes a cylinder 1 , a grid filter 4 installed in the cylinder 1 and a motor 10 for driving the grid filter 4 to rotate. As shown in Figure 3, the grid filter screen 4 of the present invention is a cylindrical filter screen with a mesh flow channel length of more than or equal to 3mm, and the grid filter screen 4 is composed of more than ten hollow ring-shaped corrugated plates 4- 1 and respectively arranged on each corrugated plate at intervals, and the lower two sides are hollow ring-shaped partitions 4-2, and the gap between the corresponding two sides of the corrugated plate 4-1 and the partition 4-2 forms a mesh flow channel, To increase the mesh density in the unit area of the grid filter 4. As shown in Figure 3, the mesh flow channel is a variable cross-section flow channel that gradually converges along the liquid flow, that is, the mesh flow channel on the grid filter is a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com