Polymerization reactor and method for producing polypropylene by employing the same

A polymerization reactor and polypropylene technology, which is applied in the field of propylene-ethylene-butene terpolymer random copolymer, can solve the problems of uneven particle size of polypropylene polymer, uneven residence time of catalyst, and backward shift of catalyst activity, etc. , to achieve the effects of reducing equipment imports, lowering the frame elevation, and prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

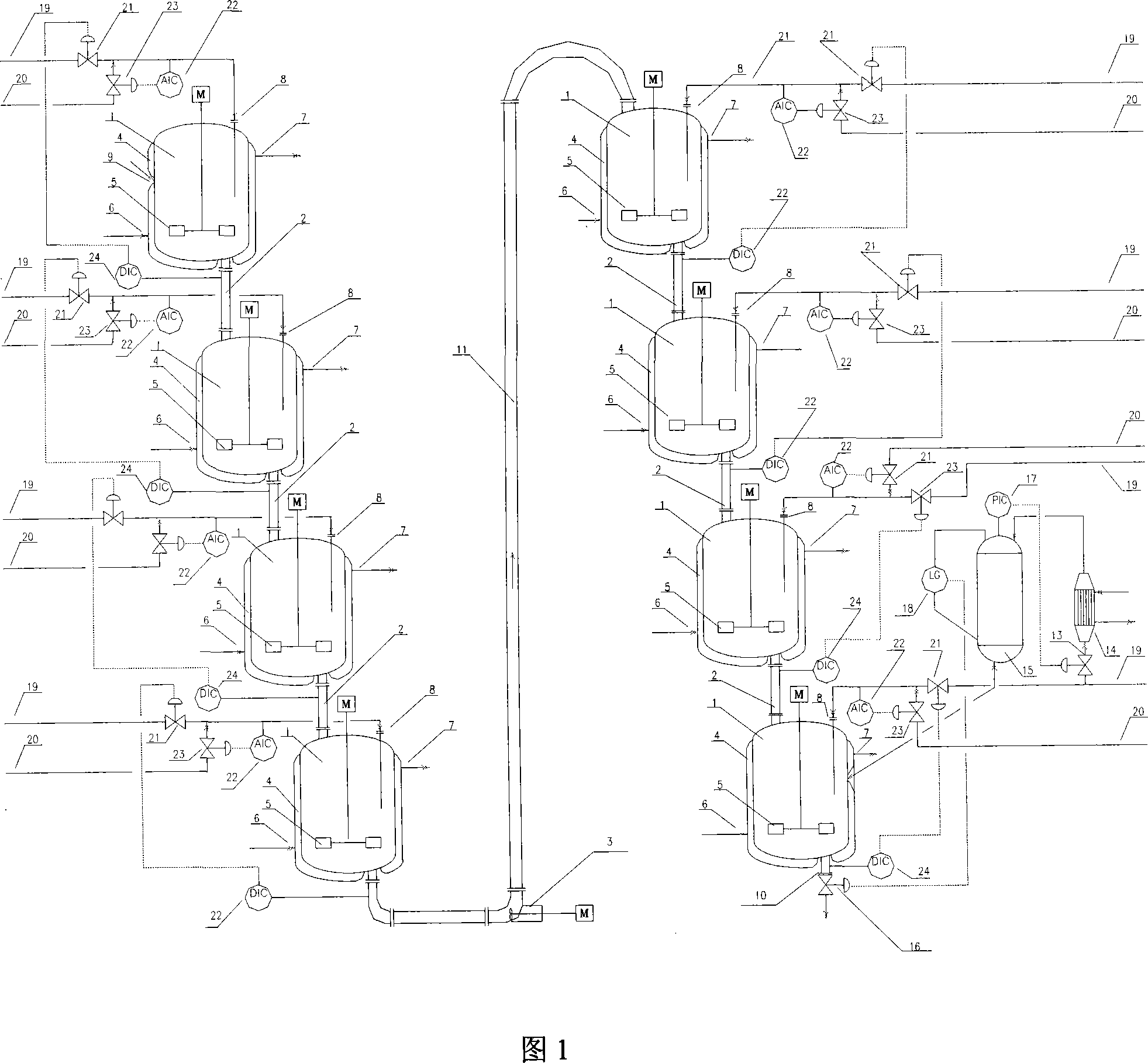

[0027] After the catalyst and cocatalyst are mixed in the pre-contact tank, they are added from the nozzle 9 of the first tank reactor, and at the same time, propylene 19 is added and hydrogen 20 or no hydrogen is added as required. In order to prevent the catalyst particles from being broken, a stirrer is used 5 Stir slowly, and control at a lower temperature, the propylene is polymerized on the particles of the catalyst, so that the catalyst is covered with a layer of polymer, providing preparation for the next step of polymerization.

[0028] The pre-polymerized catalyst enters the second tank reactor 1 by gravity flow, and polymer monomer propylene 19 is added in the reactor according to the production polymer ratio, and then hydrogen 20 is added according to the melt index of the produced product, and the hydrogen is used to adjust The molecular weight of the polymer. The catalyst continues to polymerize in the reactor. In order to uniformly remove the heat of reaction ge...

Embodiment 2

[0042] Only change the amount of hydrogen added to: control the hydrogen content of 660ppm.v in the propylene entering each reactor;

Embodiment 3

[0044] Change the amount of hydrogen added to: no addition to the first reactor, and the hydrogen content of the remaining reactors is 900ppm.v;

[0045] Except for the first reactor, for other reactors, ethylene is added to the propylene entering the reactor, and the content is controlled at about 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com