Combination compensated type wound rotor asynchronous machine

A technology for asynchronous motors and wound rotors, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., and can solve the problems of complex starting devices and large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

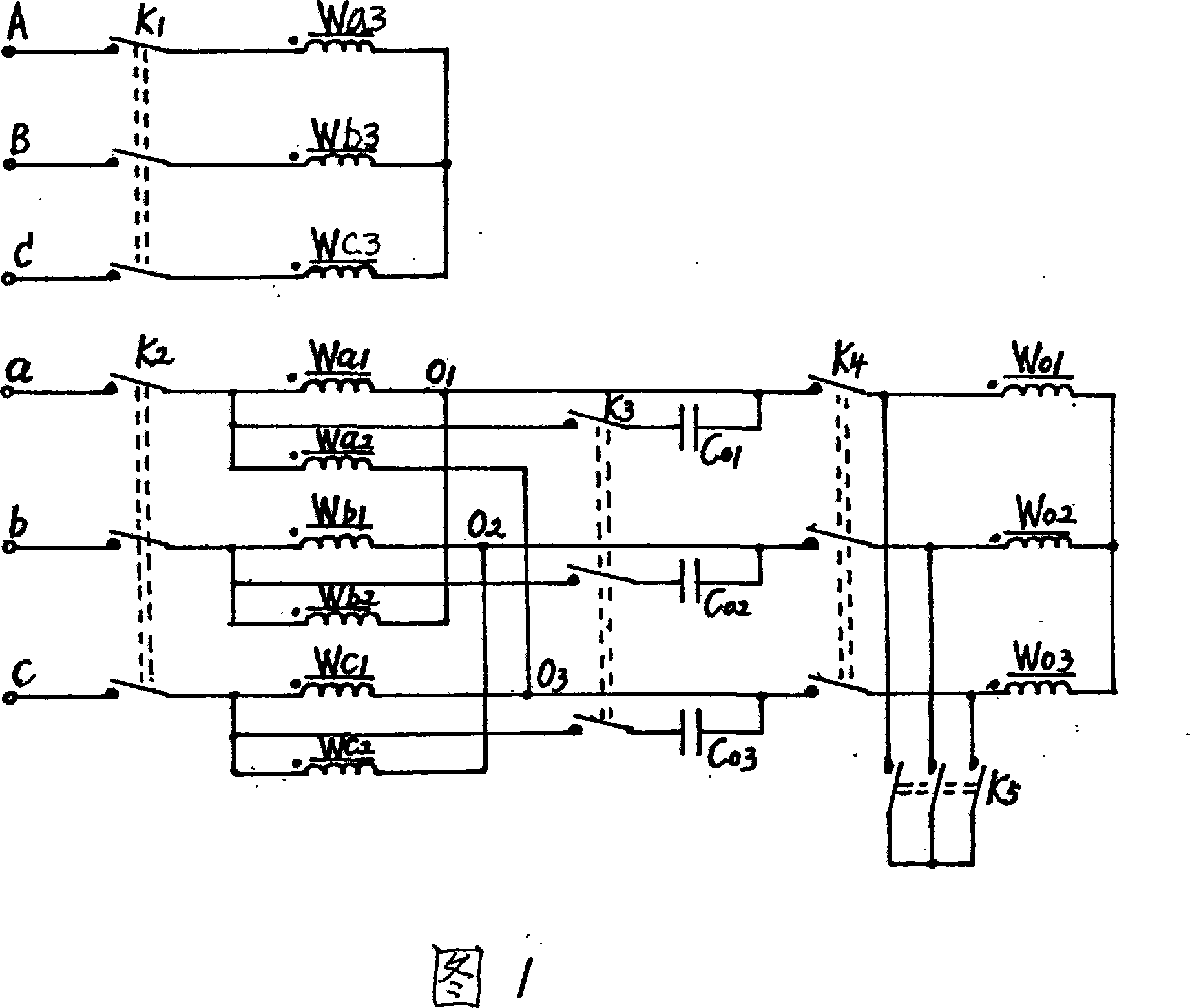

[0013] Example 1 (as shown in Figure 1)

[0014] Combined compensation type wound rotor asynchronous motor, including stator windings and rotor windings. The stator windings are connected into two or three groups of three-phase windings. At least two groups of three-phase windings are connected to have three compensation terminals whose potential value is close to zero. O 1 , O 2 , O 3 Combination wiring, its three compensation terminals O 1 , O 2 , O 3 Through switch K4 and the rotor winding W in star connection 01 -W 02 -W 03 The three wire ends are connected, and the rotor winding W 01 -W 02 -W 03 The three wire ends of is connected to a switch group K5 consisting of three switches in star connection. Switch K4 and switch group K5 adopt AC contactors.

[0015] In this embodiment, the stator windings are connected into three groups of three-phase windings Wa 1 -Wb 1 -Wc 1 , Wa 2 -Wb 2 -Wc 2 , Wa 3 -Wb 3 -Wc 3 , Two sets of three-phase winding Wa 1 -Wb 1 -Wc 1 , Wa 2 -Wb 2 -Wc 2 ...

Embodiment 2

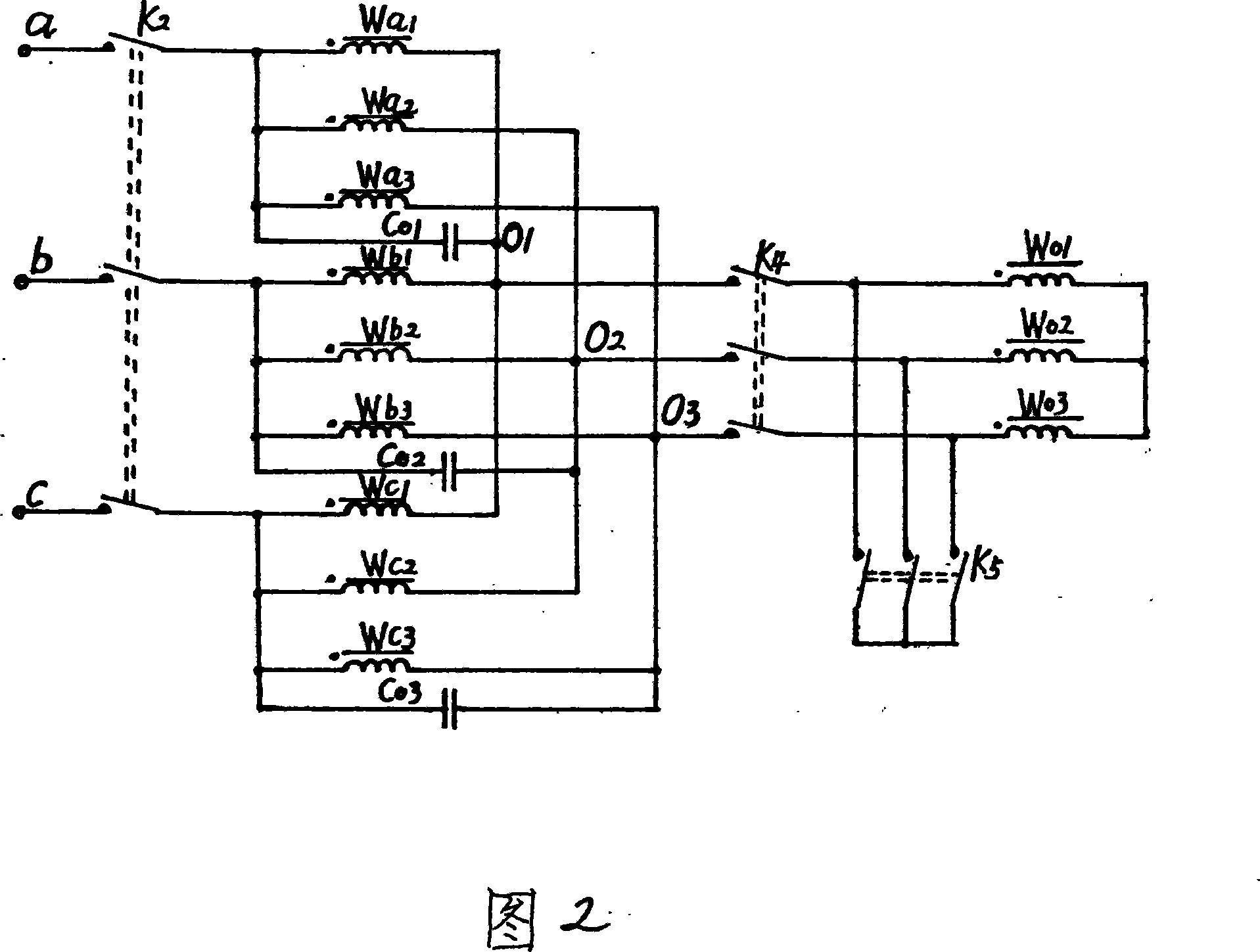

[0020] Example 2 (as shown in Figure 2)

[0021] Combined compensation type wound rotor asynchronous motor, including stator windings and rotor windings. The stator windings are connected into two or three groups of three-phase windings. At least two groups of three-phase windings are connected to have three compensation terminals whose potential value is close to zero. O 1 , O 2 , O 3 Combination wiring, its three compensation terminals O 1 , O 2 , O 3 Through switch K4 and the rotor winding W in star connection 01 -W 02 -W 03 The three wire ends are connected, and the rotor winding W 01 -W 02 -W 03 The three wire ends of is connected to a switch group K5 consisting of three switches in star connection. Switch K4 and switch group K5 adopt AC contactors.

[0022] In this embodiment, the stator windings are connected into three groups of three-phase windings Wa 1 -Wb 1 -Wc 1 , Wa 2 -Wb 2 -Wc 2 , Wa 3 -Wb 3 -Wc 3 , Three groups of three-phase winding Wa 1 -Wb 1 -Wc 1 , Wa 2 -Wb 2 -W...

Embodiment 3

[0025] Combined compensation type wound rotor asynchronous motor, including stator windings and rotor windings. The stator windings are connected into two or three groups of three-phase windings. At least two groups of three-phase windings are connected to have three compensation terminals whose potential value is close to zero. O 1 , O 2 , O 3 Combination wiring, its three compensation terminals O 1 , O 2 , O 3 Through switch K4 and the rotor winding W in star connection 01 -W 02 -W 03 The three wire ends are connected, and the rotor winding W 01 -W 02 -W 03 The three wire ends of is connected to a switch group K5 consisting of three switches in star connection. Switch K4 and switch group K5 adopt AC contactors.

[0026] In this embodiment, the stator windings are connected into two groups of three-phase windings Wa 1 -Wb 1 -Wc 1 , Wa 2 -Wb 2 -Wc 2 , Two sets of three-phase winding Wa 1 -Wb 1 -Wc 1 , Wa 2 -Wb 2 -Wc 2 Connected to have three compensation terminals O whose potentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com