Temperature self-compensation optical fiber/optical grating dynamic strain measurement method and system

A fiber grating and dynamic strain technology, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of unable to achieve kilohertz and above demodulation, high frequency, short duration, etc., and achieve small dynamic range and high temperature Stability, the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

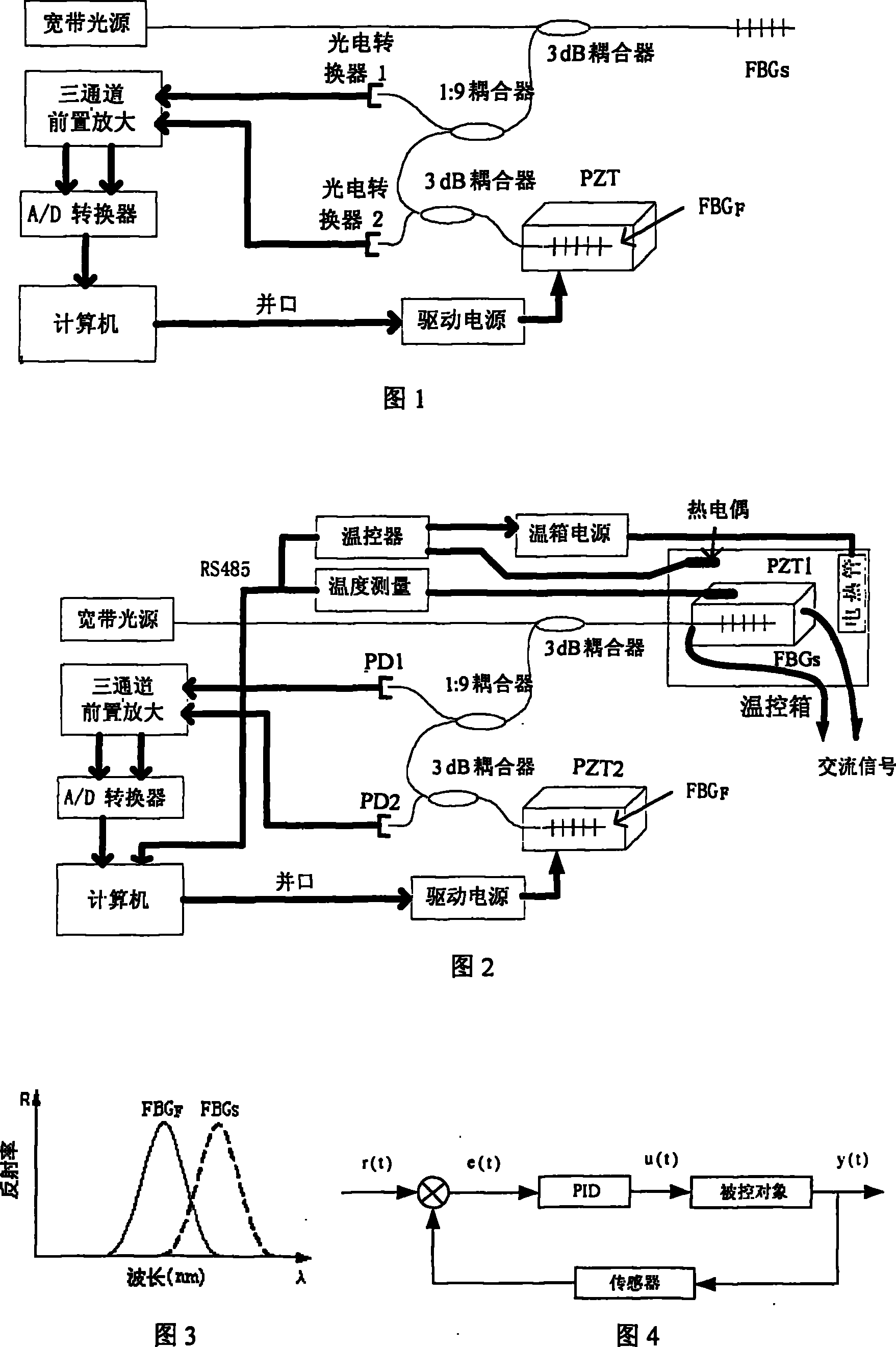

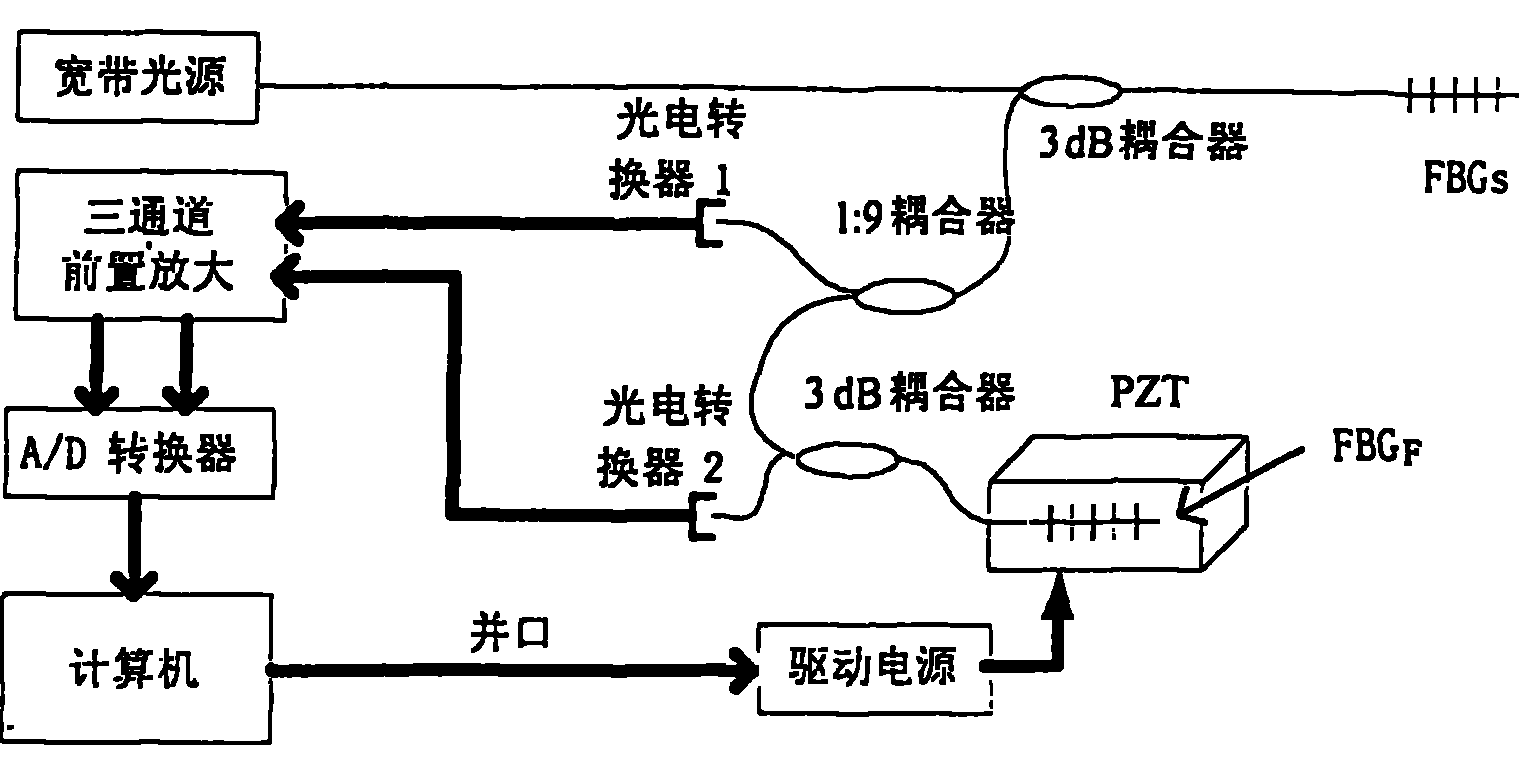

[0020] Referring to Figure 1, the system of the present invention is mainly composed of two parts: an optical sensor system and an electrical measurement system. Among them, the optical system includes broadband light source, coupler, sensing fiber Bragg grating (FBG S ) And filtered fiber Bragg grating (FBG F )composition. The electrical system mainly consists of photodiode (PD), preamplifier, A / D converter, computer, electrostrictive material (PZT) and electrostrictive material drive power supply. In the figure, the thin connecting lines represent optical fibers, and the thick connecting lines represent electrical signal connecting lines.

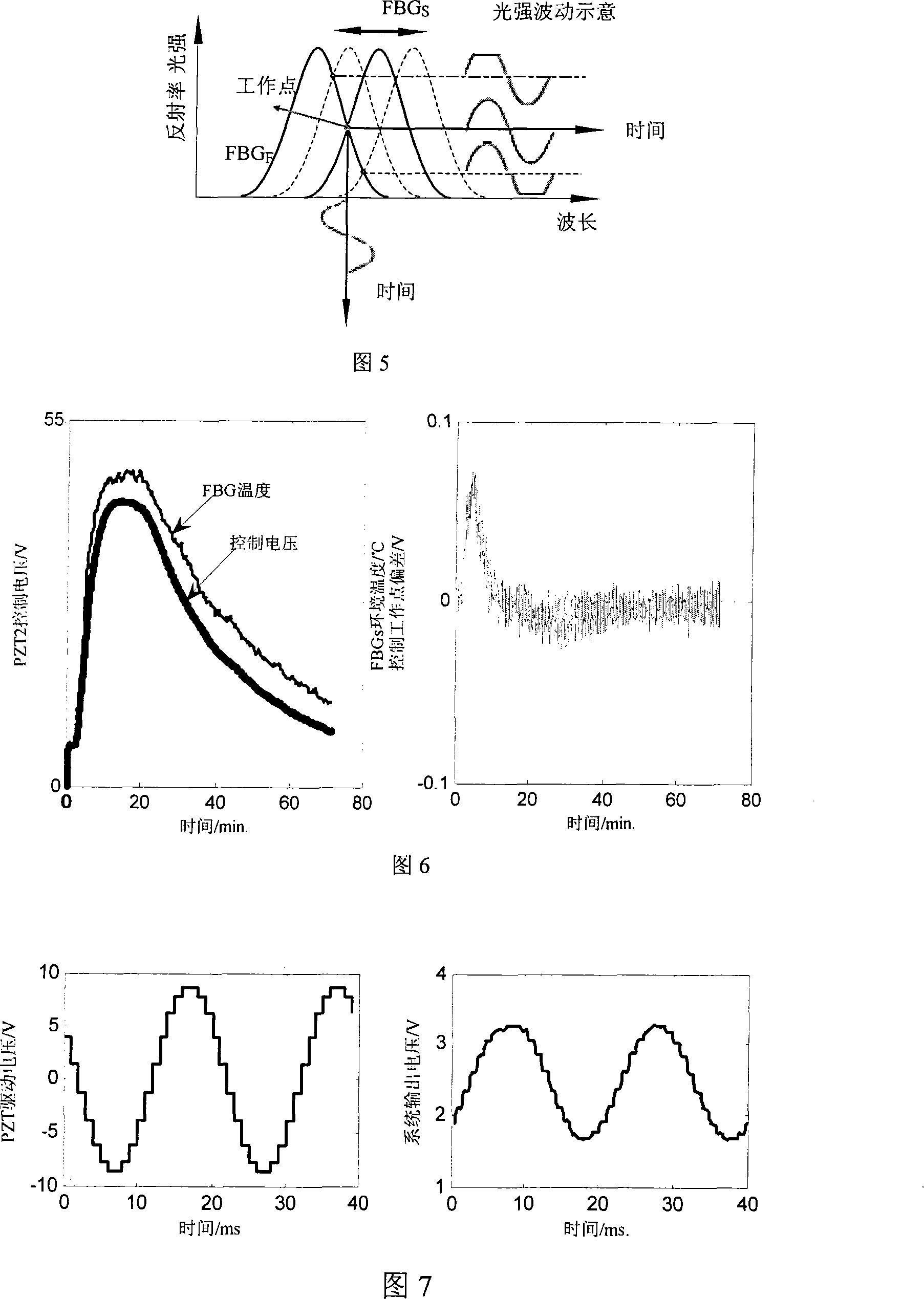

[0021] Referring to Figure 2, it is an experiment of the above-mentioned system of the present invention for temperature disturbance, which can monitor the temperature control box in real time. The temperature control system is mainly composed of a temperature control box, a temperature box power supply, a thermostat, a temperature measurin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com