Cooling type packaging member production method and its applied cooling structure

A heat dissipation structure and packaging technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of warpage of heat sinks, small space, waste of process materials, etc., and achieve the effect of avoiding warpage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

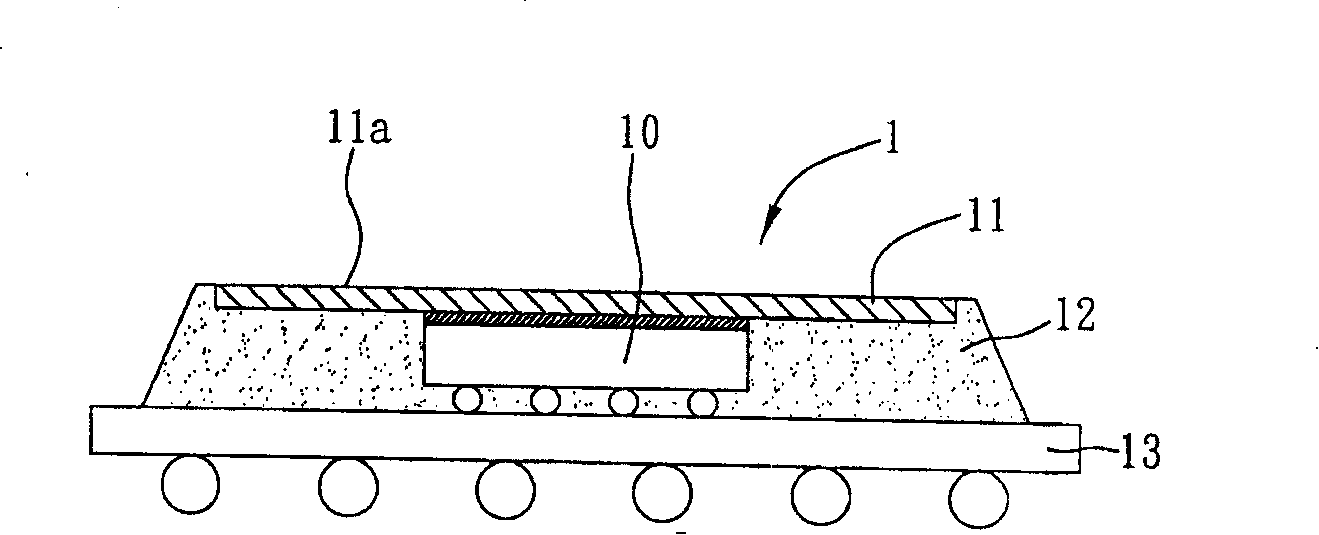

[0069] see Figure 4A to Figure 4F , is a schematic diagram of the first embodiment of the manufacturing method of the heat dissipation package of the present invention. The manufacturing method of the heat-dissipating package of the present invention can be used on a single chip carrier or batch-wise to process on a module chip with multiple chip carriers according to requirements.

[0070] Such as Figure 4A and Figure 4B shown, where the Figure 4B for corresponding to Figure 4A In the top view, firstly, the semiconductor chip is connected and electrically connected to the chip carrier 43 , and a heat dissipation structure 41 is connected to the semiconductor chip 40 .

[0071] The heat dissipation structure 41 includes a body 410 having a first surface 41a and a second surface 41b opposite to the first surface 41a, and a propping portion 411 protruding from the edge of the body 410 toward the first surface 41a, and on the first surface of the heat dissipation structu...

no. 2 example

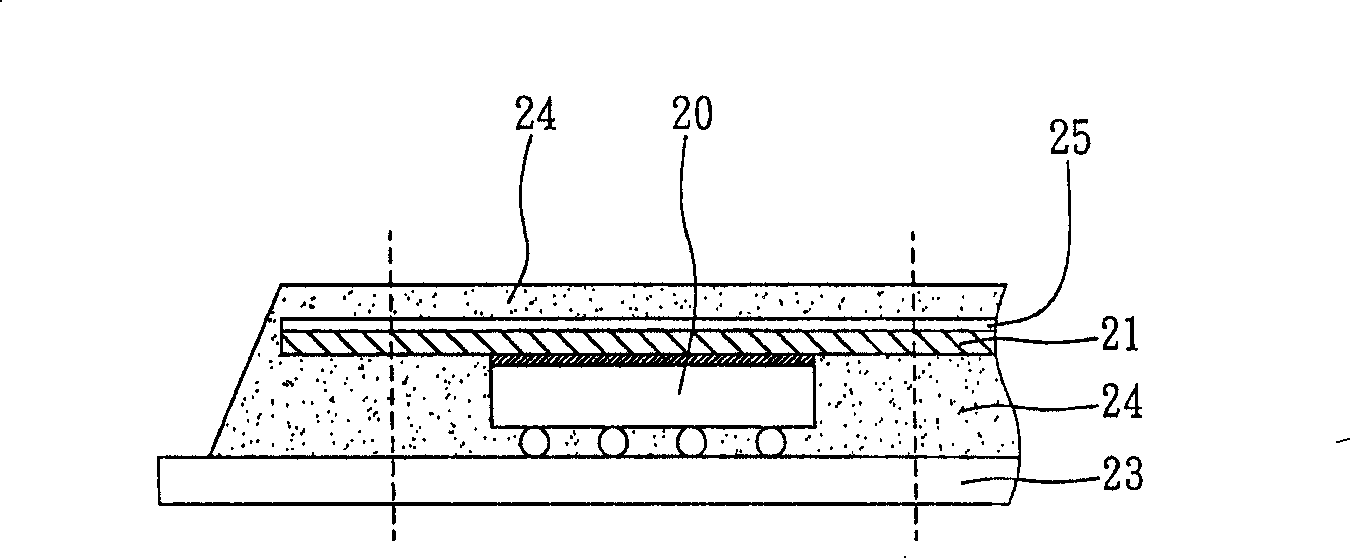

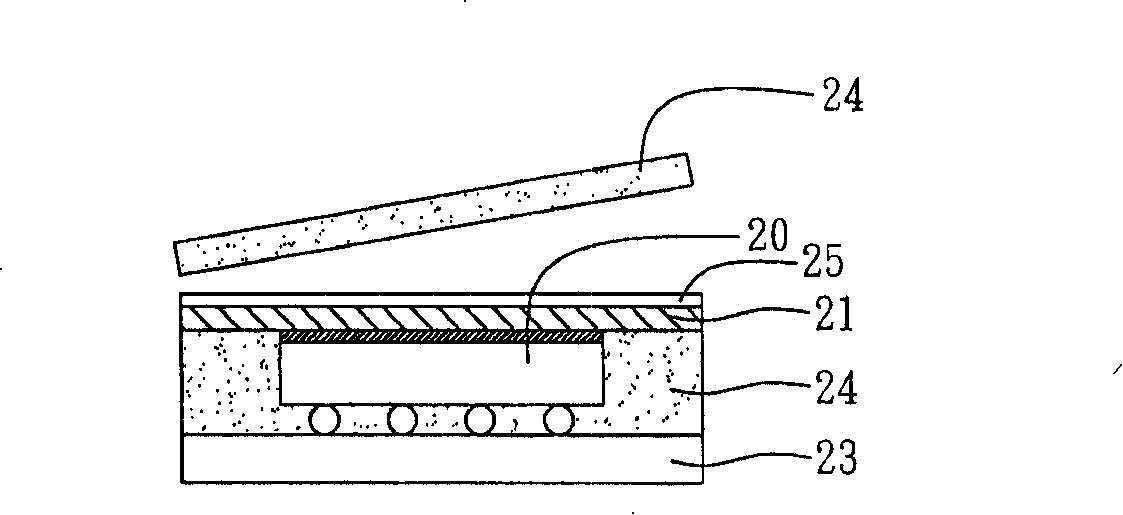

[0081] see Figure 6 , is a schematic diagram of the second embodiment of the manufacturing method of the heat dissipation package of the present invention. The manufacturing method of the heat-dissipating package of this embodiment is substantially the same as that of the previous embodiment, the main difference being that the material of the covering layer 65 formed on the heat-dissipating structure 61 is, for example, film, epoxy resin (epoxy), or wax (wax). The organic layer, its bonding force with the encapsulant 64 is greater than its bonding force with the heat dissipation structure 61, so during the removal operation, the covering layer 65 and the encapsulating compound 64 on the covering layer 65 will be removed at the same time, so as to The upper surface of the heat dissipating structure 61 is directly exposed, and then the heat of the semiconductor chip 60 is led out.

no. 3 example

[0083] see Figure 7 , is a schematic diagram of the third embodiment of the manufacturing method of the heat dissipation package of the present invention. As shown in the figure, the manufacturing method of the heat-dissipating package in this embodiment is substantially the same as that of the previous embodiments, the main difference is that a wire-bonded semiconductor chip 70 is placed on a chip carrier 73, and a plurality of bonding wires 700 is electrically connected to the chip carrier 73, and a spacer layer 78 such as a waste chip or a heat sink can be placed on the semiconductor chip 70, so that the heat dissipation structure 71 is connected to the semiconductor chip through the spacer layer 78 70 , preventing the heat dissipation structure 71 from touching the bonding wire 700 .

[0084] Therefore, the manufacturing method of the heat-dissipating package and the heat-dissipating structure used in the present invention are mainly to connect a heat-dissipating structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com