Etching terminal checking device and method for plasma etching equipment

An etching equipment and endpoint detection technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of high cost of testing equipment, difficulty in software integration and development, CCD stability, Problems such as signal noise and insufficient sensitivity can ensure the normal silicon wafer processing process, ensure the quality of silicon wafer processing, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

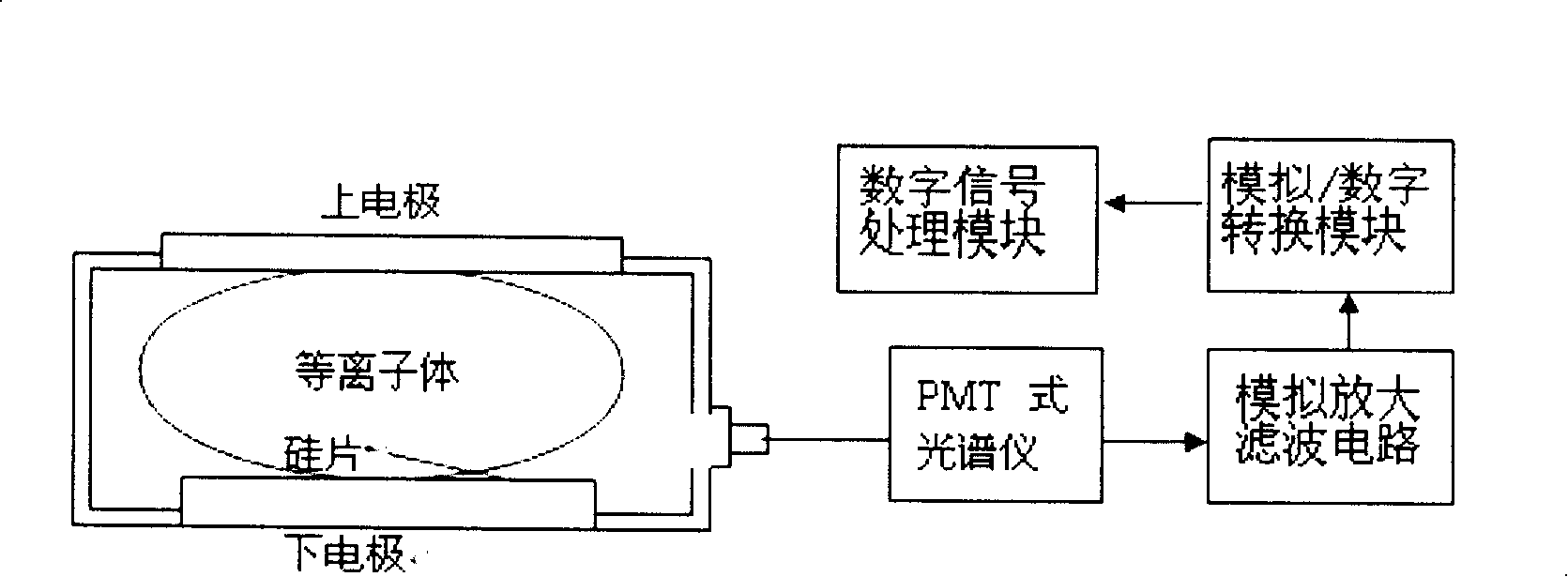

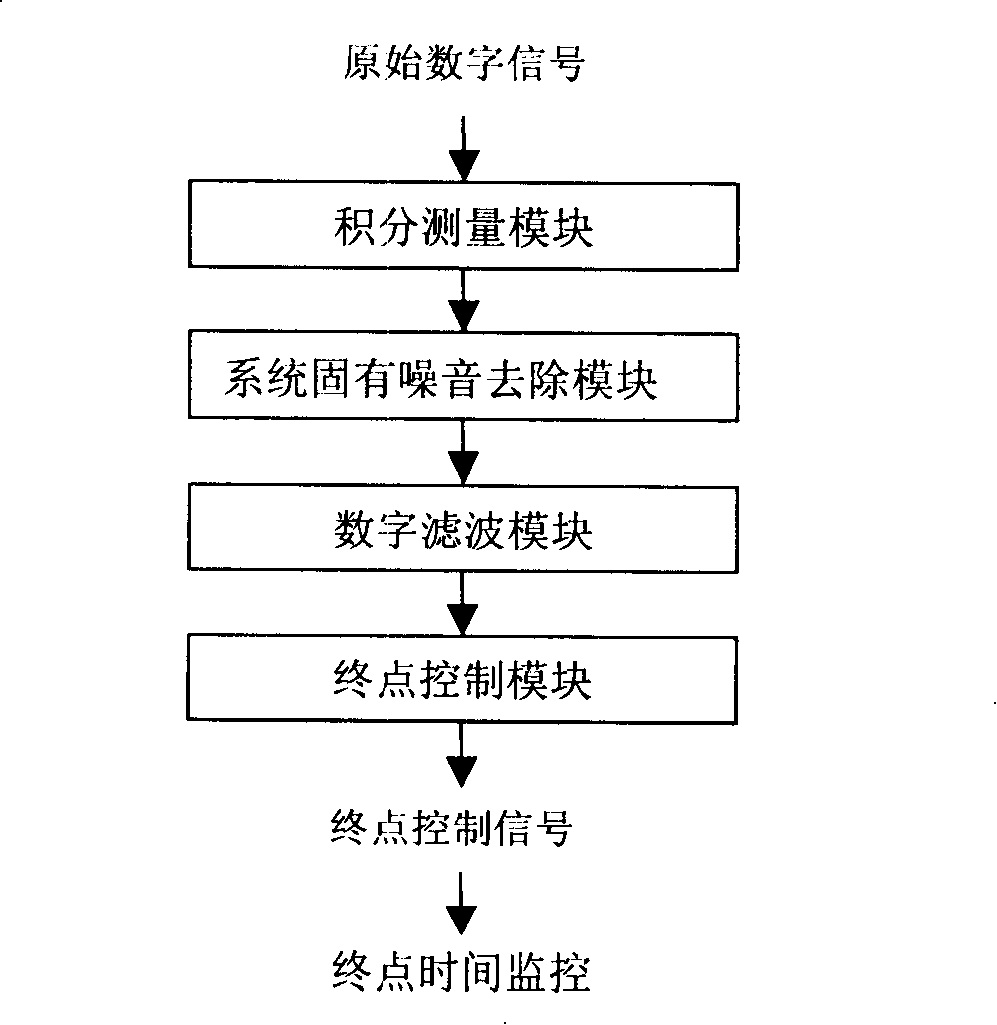

[0030] The etching terminal detection device of a plasma etching equipment according to the present invention, its specific implementation method is as follows figure 1 As shown, it includes a spectrometer, an analog amplification and filtering circuit, an analog / digital conversion module and a digital signal processing module, wherein,

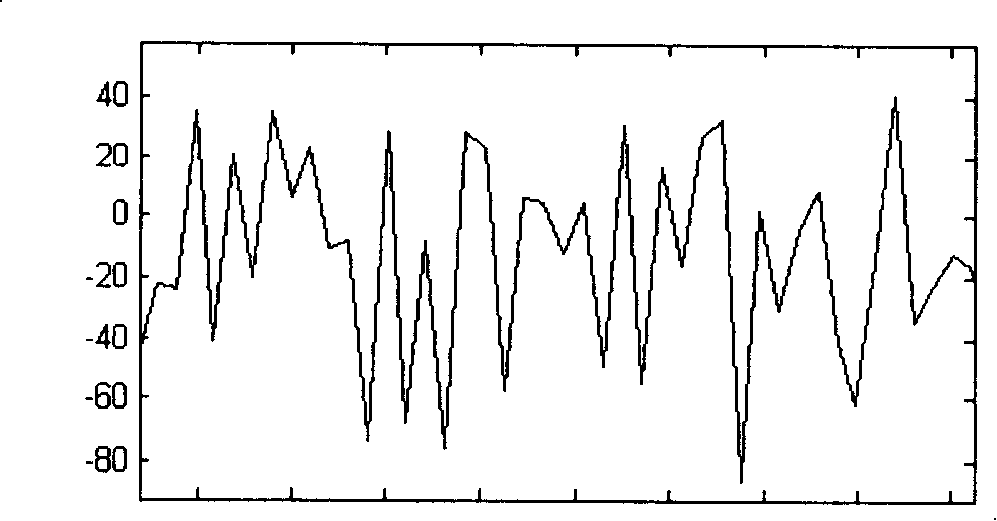

[0031] The spectrometer converts the detected optical signal inside the plasma etching equipment into an analog electrical signal output; the spectrometer is a photomultiplier tube PMT spectrometer, and the PMT receives the spectrum emitted by the plasma in the plasma etching equipment and converts the light The signal is converted into an analog electrical signal. Specifically, during the etching process, the spectrum emitted by the plasma in the reaction chamber of the plasma etching equipment is received by the photomultiplier tube of the PMT spectrometer, and the light intensity change of the spectral signal in the reaction chamber is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com