Air-floating type multidimensional force sensor and multidimensional force measuring method

A multi-dimensional force sensor and air-floating technology, applied in the measurement of hydraulic/pneumatic force, simultaneous measurement of multiple hydraulic valves, measurement devices, etc., can solve problems such as inability to achieve decoupling and complex decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

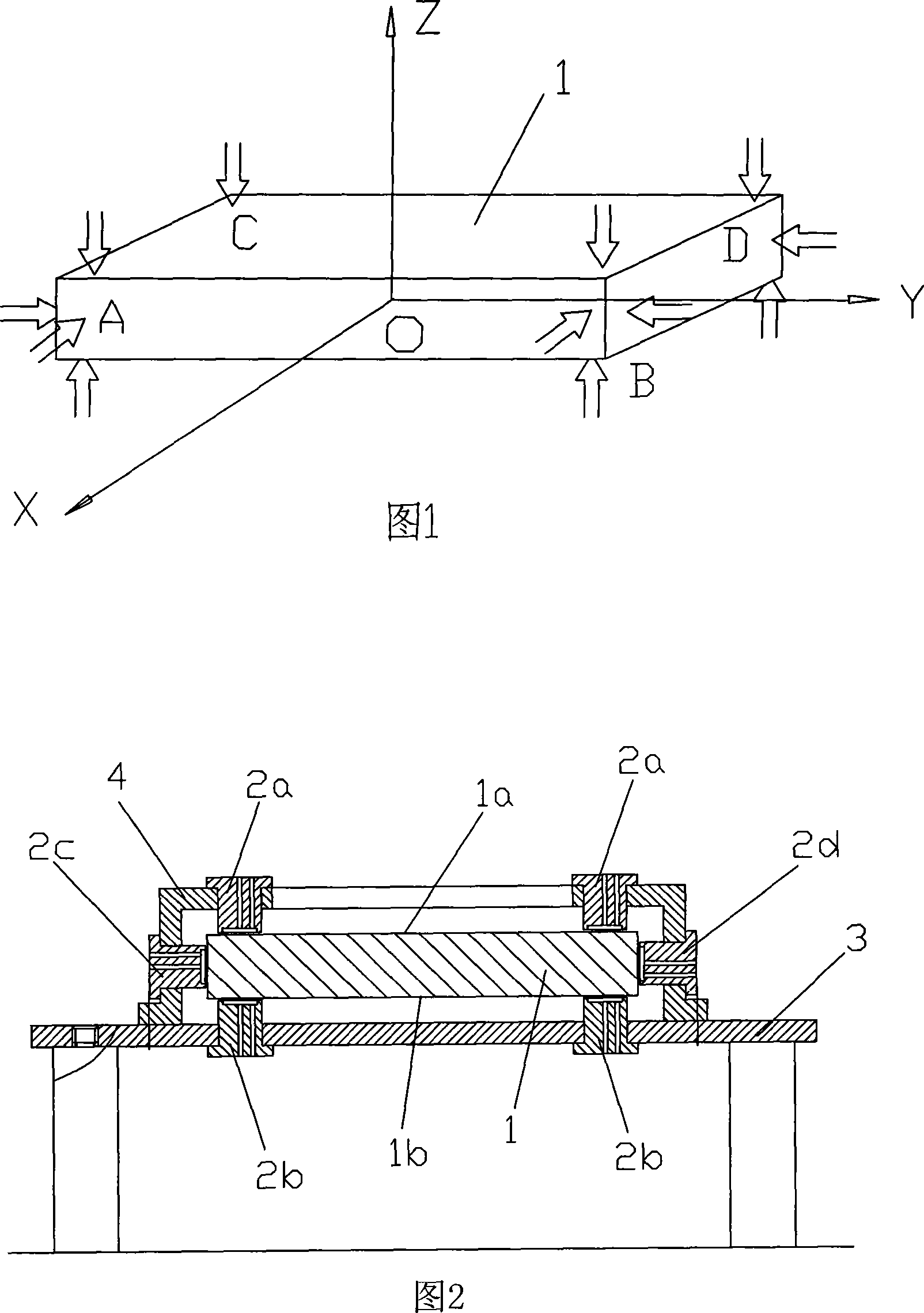

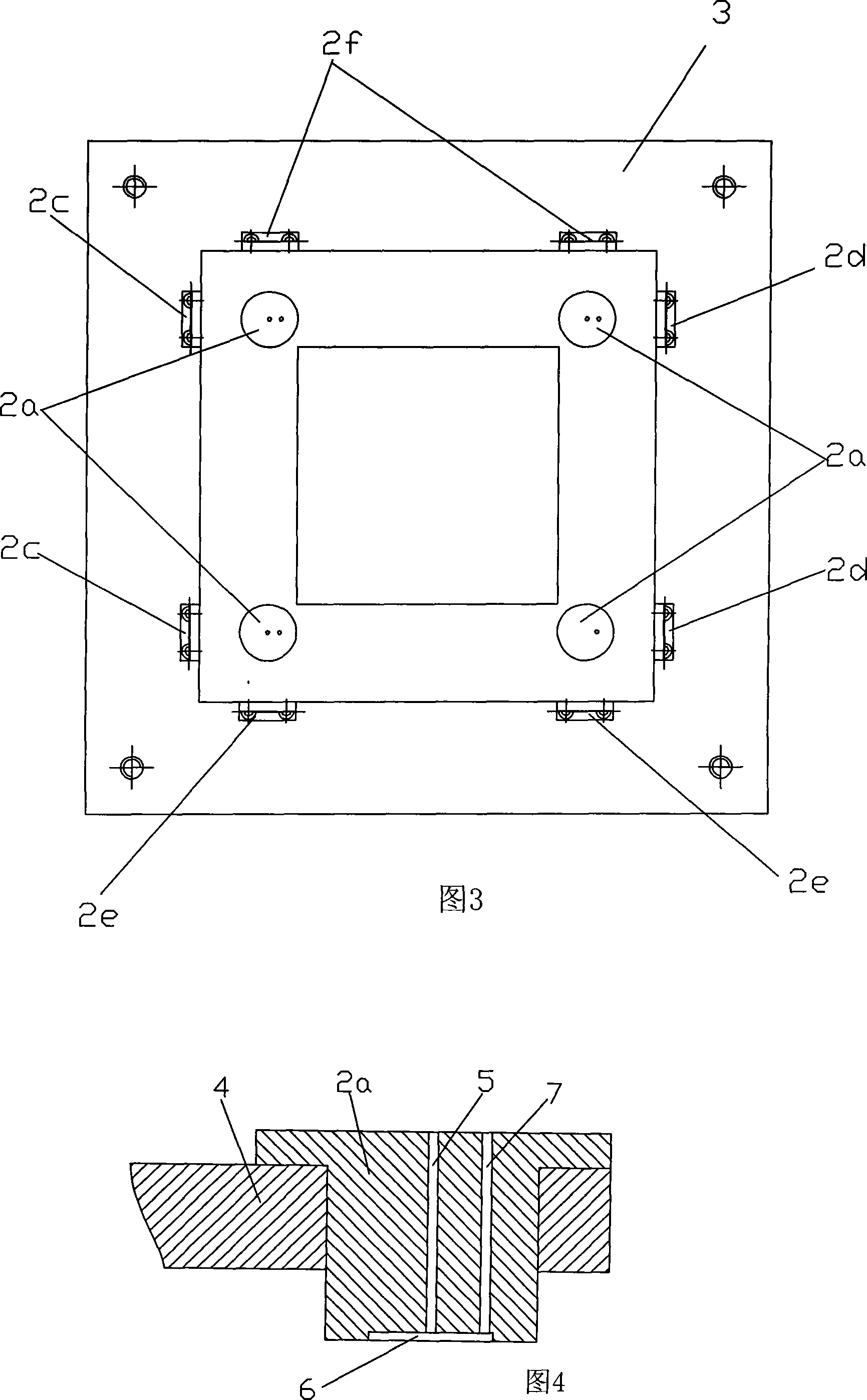

[0017] Labels in the figure: 1 floating plate, 1a floating plate top surface, 1b floating plate bottom surface, 1c floating plate left side, 1d floating plate right side, 1e floating plate front side, 1f floating plate rear side, 2a top surface nozzle, 2b bottom surface nozzle, 2c Left nozzle, 2d right nozzle, 2e front nozzle, 2f rear nozzle, 3 working table, 4 nozzle bracket, 5 air inlet, 6 pressure chamber, 7 pressure measuring port.

[0018] Referring to Fig. 1, in order to realize the measurement of the six-dimensional force, a rectangular hexahedron floating plate 1 is set in this embodiment, corresponding to each surface of the floating plate 1, nozzles are respectively provided, and the nozzle baffle is formed by the surface corresponding to each nozzle and the floating plate A plate-type pressure sensor, and the floating plate 1 as a baffle is completely suspended under the action of the air pressure of each nozzle, and the air cavity pressure signal of each nozzle is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com