Smoke and dust comprehensive processing technique, smoke and dust trapping device and combined dust remover for electric arc furnace

A comprehensive treatment, electric arc furnace technology, applied in chemical instruments and methods, lighting and heating equipment, dispersed particle separation, etc., can solve the problems of temperature uncertainty, poor stability, difficult control, etc. The effect of high resistance and high trap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

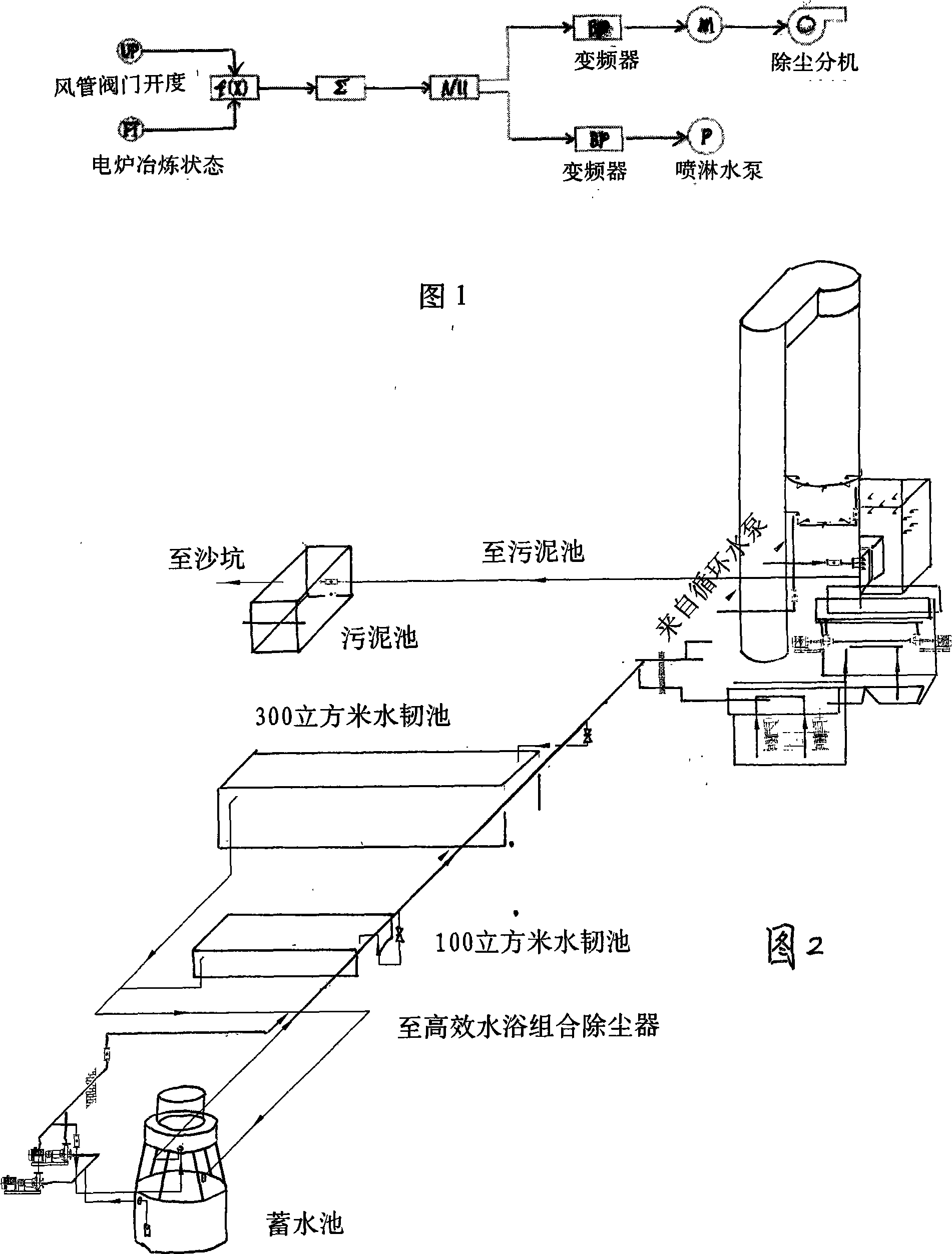

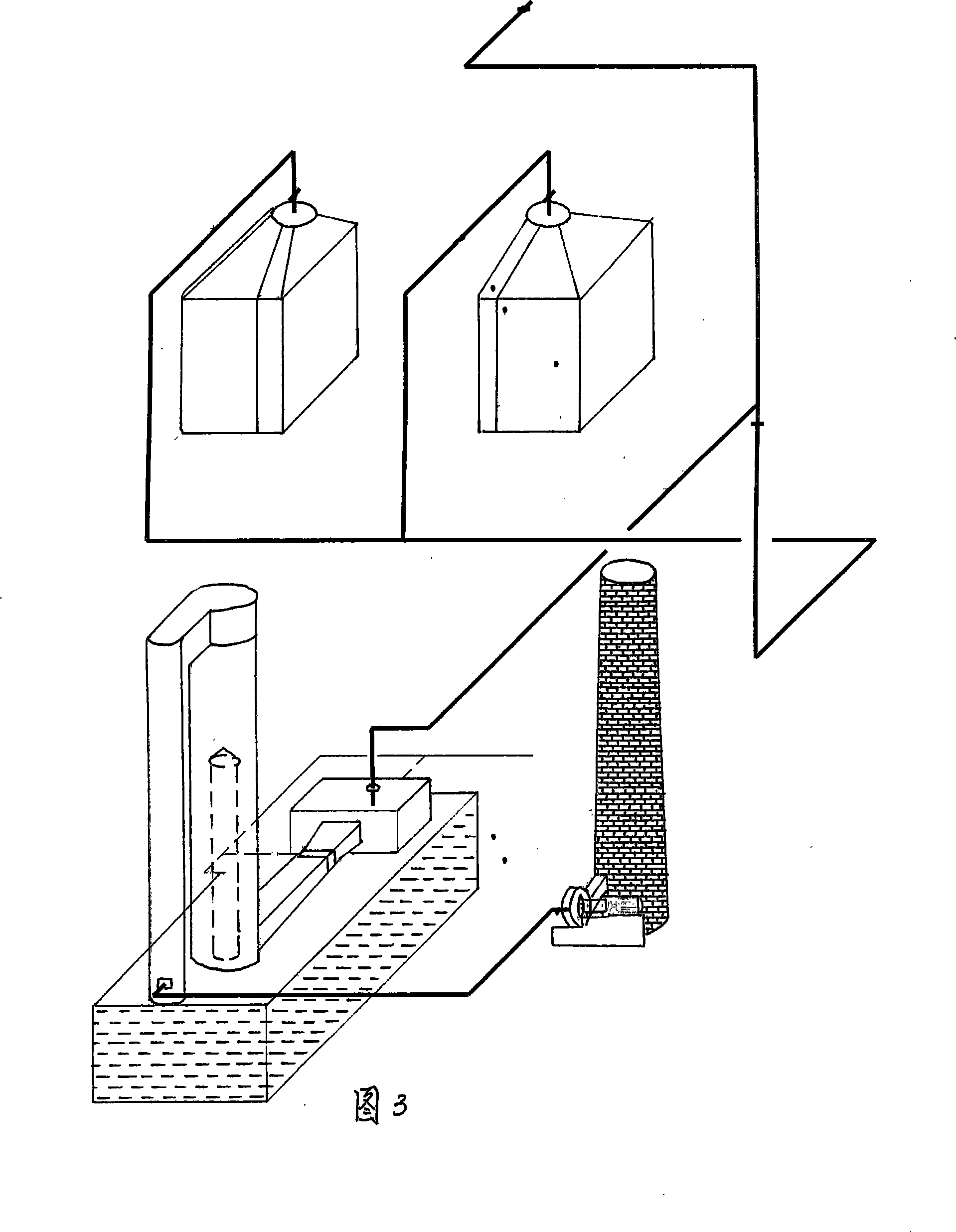

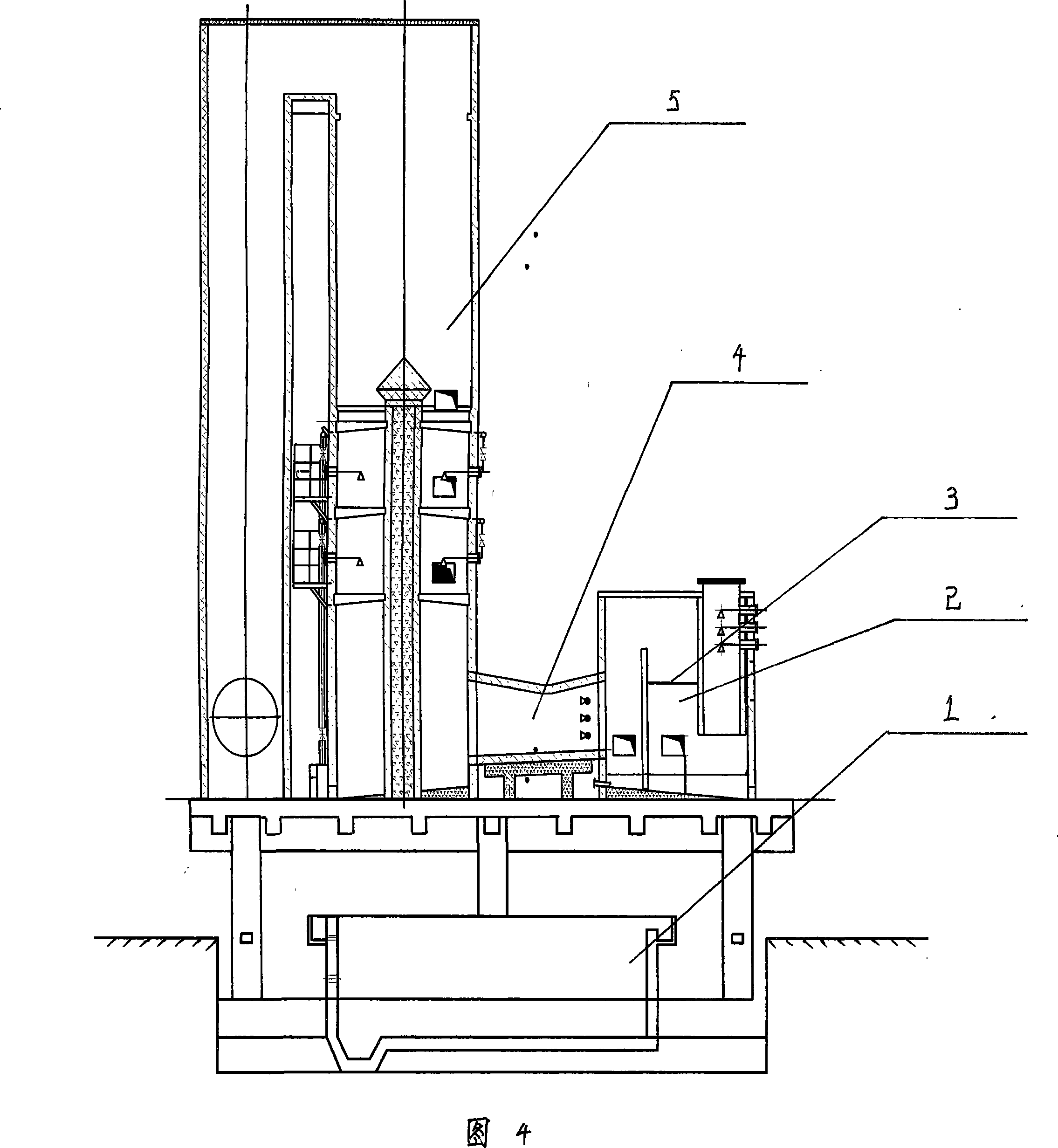

[0041] As shown in the accompanying drawings, the system composition of the present invention includes:

[0042] Dust removal system: The water bath comprehensive treatment is to use circulating water to fully contact with the flue gas, absorb the smoke and dust in the flue gas in the circulating water, and achieve the purpose of dust removal. Using water bath, Venturi, and stone dust collectors, the flue gas is absorbed into the circulating water through static pressure dust cleaning, dynamic pressure dust suction, centrifugation and density dust collection, and then separated by sedimentation.

[0043] Dust collection system: The electric arc furnace is an open flue gas discharge structure. The flue gas is discharged in an unorganized manner. The collection of the flue gas is the key. The mobile open and close semi-closed cover can be used to solve the problem systematically. The problems of feeding, shaking the furnace, and tapping Fume collection for start-up and smelting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com