Cryostat for transporting cooled equipment at a cryogenic temperature

A technology of cryostat and cooling equipment, which can be applied to machines, mechanical equipment, heat exchange equipment, etc. that use refrigerant evaporation, and can solve problems such as reducing vacuum quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

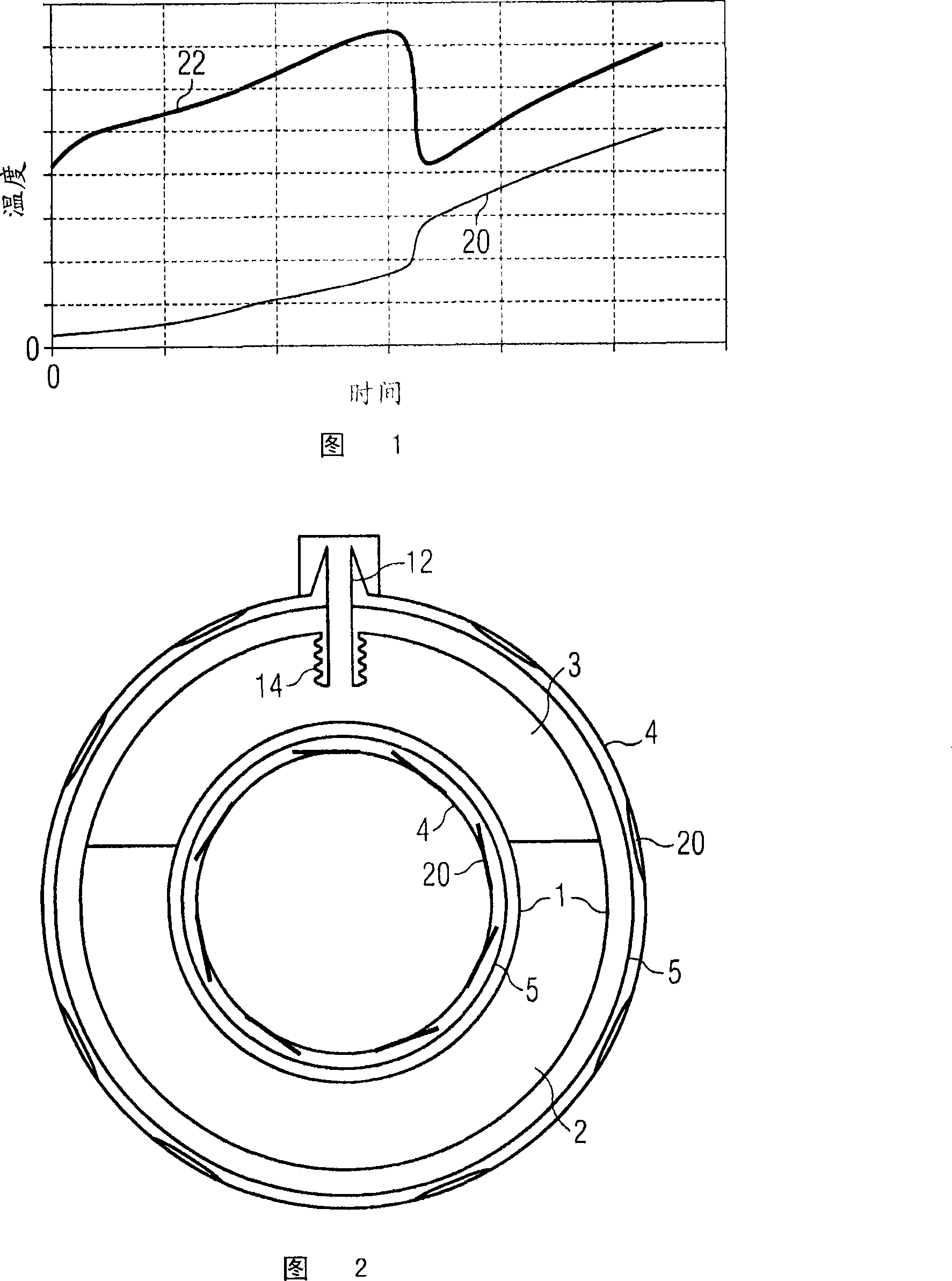

[0012] Although many known cryogenically cooled devices, such as the magnets used in magnetic resonance imaging (MRI) systems, operate at liquid helium temperatures (approximately 4K), delivering such systems at liquid helium temperatures would be difficult and expensive because Liquid helium is costly and has limited availability. Thus, the cooling device may only be provided with a limited amount of liquid helium for delivery, which may be exhausted before the cooling device reaches its destination. The cooling device may then become hot due to heat inflow, as described above.

[0013] As described above, the insulation effect of the vacuum insulation layer is reduced due to the presence of vacuum contaminants. Many of these contaminants are solid at the temperature of liquid helium, but evaporate when the device heats up. This in turn means that the heat influx into the cooling device increases rapidly at the boiling temperature of the vacuum contaminants. Typically, thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com