Axial fan for cooling electronic component

A technology of electronic components and axial flow fans, applied to pump components, components of pumping devices for elastic fluids, instruments, etc., can solve problems such as limited cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

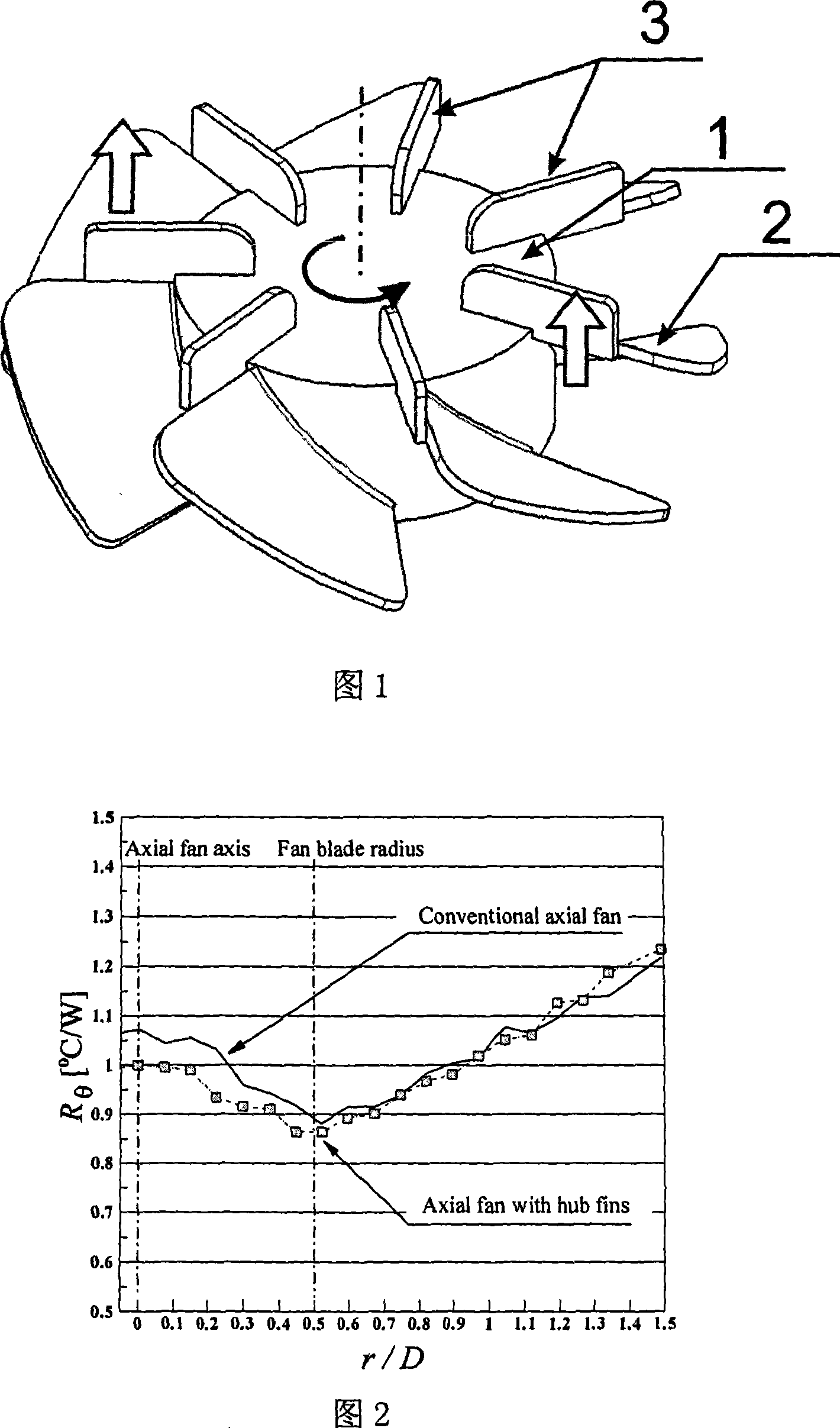

[0009] Referring to Fig. 1, the present invention includes a hub 1 located at the center of the fan main body and a main blade 2 fixed on the outside of the hub 1, and a square attachment blade 3 is also arranged on the hub 1, the attachment blade 3 is 16 mm long, 6 mm wide, and thick. 1.6mm. Except for the edges attached to both sides of the hub 1 and the trailing edge of the main blade 2, the other sides of the attached blade 3 are trimmed to be as smooth as possible. The length of the attached blade 3 with a total length of 16 mm on the central hub 1 is 10 mm, and the length on the trailing edge of the main blade 3 is 6 mm. Since the attached blades 3 are arranged on the central hub 1, the weight of the present invention is increased by 15%. Since the DC voltage driving the axial fan remains unchanged (12DCV), the speed of the fan is correspondingly redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com