Method for producing nano-fibre film with macromolecular solution electrostatic filature and implementing equipment

A nanofiber membrane and electrospinning technology, which is applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problem of limited viscosity range of electrospinning liquid, difficulty in electrospinning of solution, and non-rigid storage tank of electrospinning liquid. issues of closure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

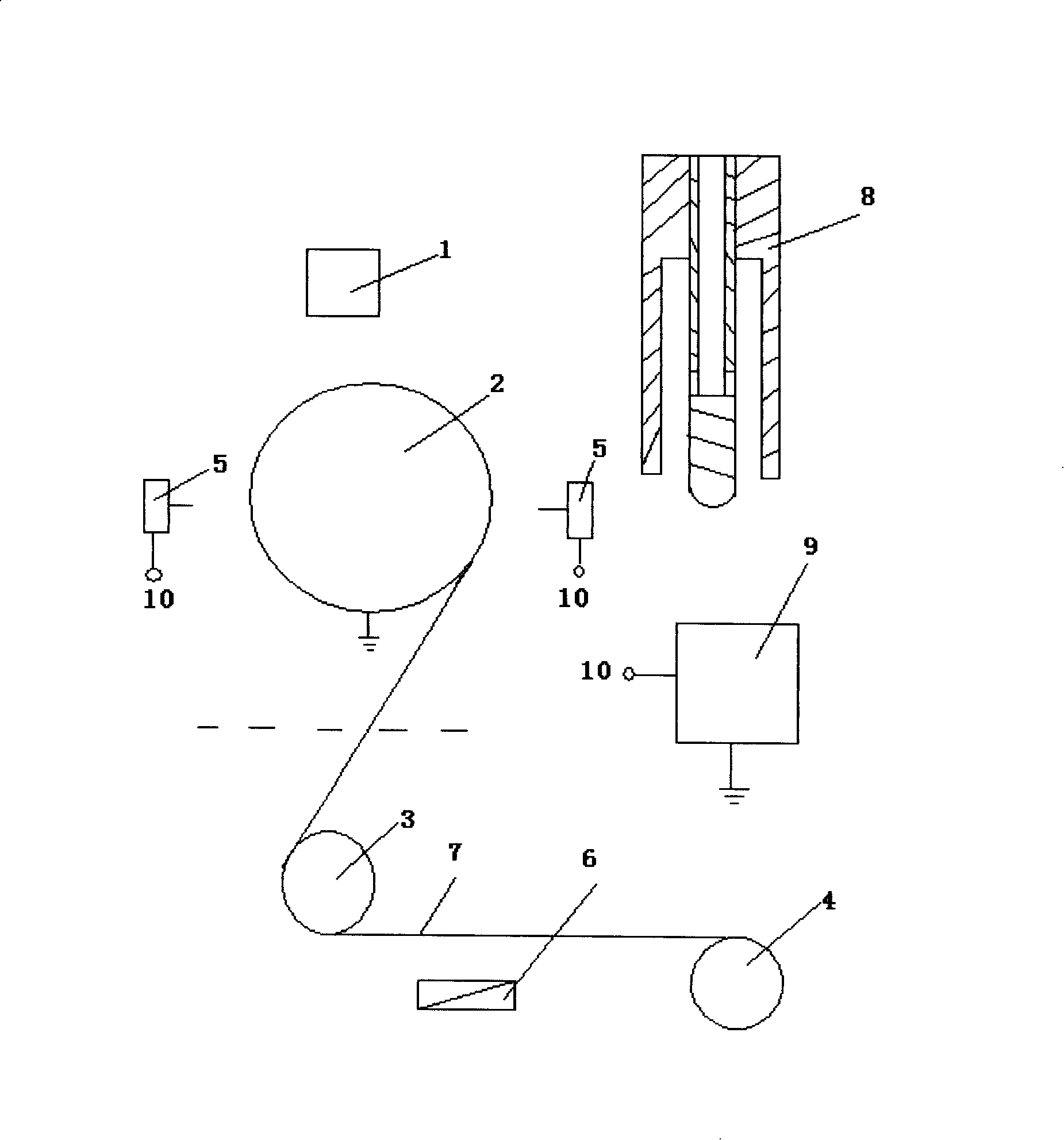

[0009] Example 1. Polyvinylidene fluoride (PVDF) was used as the electrospun material, the molecular weight Mw=800,000, dimethylformamide (DMF) was used as the solvent, and acetone was used as the regulator. An electrospinning solution with a PVDF content of 8% was prepared with a mixed solvent of DMF:acetone=8:2 (V / V), and its viscosity was 300 centipoise. The nanofiber membrane is prepared by using the electrospinning membrane forming device of the present invention. The electrospinning liquid is transported to the liquid storage tank 1 by an automatic infusion pump, and then flows into the liquid storage tank of the nozzle group 5 . Then the electrospinning solution passes through the inner small cylinder of the double-layer structure cylinder nozzle, and flows out from the top of the outer cylinder. The high-voltage end of the DC high-voltage power supply is connected to the nozzle group 5, and the other end is grounded, and the wire connecting cylinder is also connected ...

example 2

[0010] Example 2. Polyacrylonitrile (PNA) was used as the electrospun material, the molecular weight Mw=65,000, and dimethylformamide (DMF) was used as the solvent. A solution with a PNA content of 10% was prepared with a viscosity of 280 centipoise. The nanofiber membrane is prepared by using the electrospinning membrane forming device of the present invention. Control the electrospinning voltage to 23,000 volts, the temperature to 30°C, and the distance between the nozzle and the wire-connecting cylinder to be 180mm. A nanofibrous membrane with a thickness of 25 μm and a porosity of 75% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com