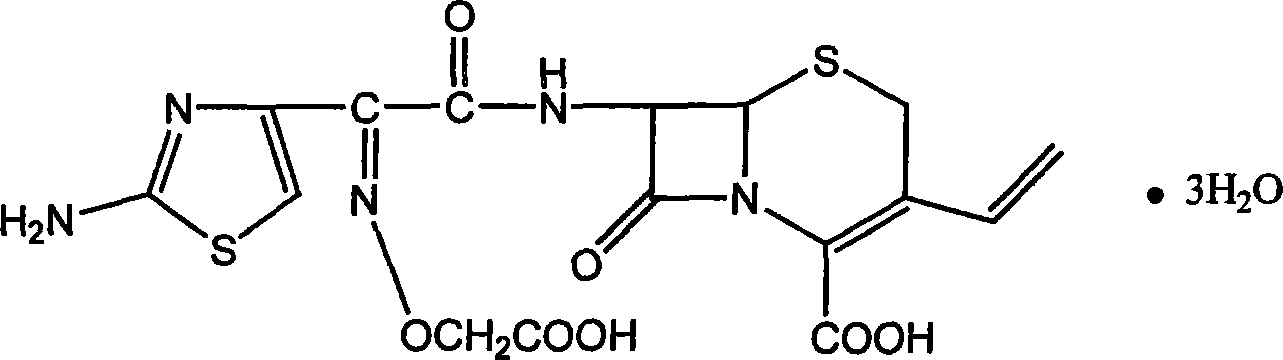

Preparation of cefixime cephalosporin and fine purification method

A technology of cefixime and a refining method, applied in the field of oral cephalosporins, can solve the problems of low reaction process stability, uneven product quality, inconvenient industrialized production, etc., and achieve considerable economic benefits, good product quality and convenience The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

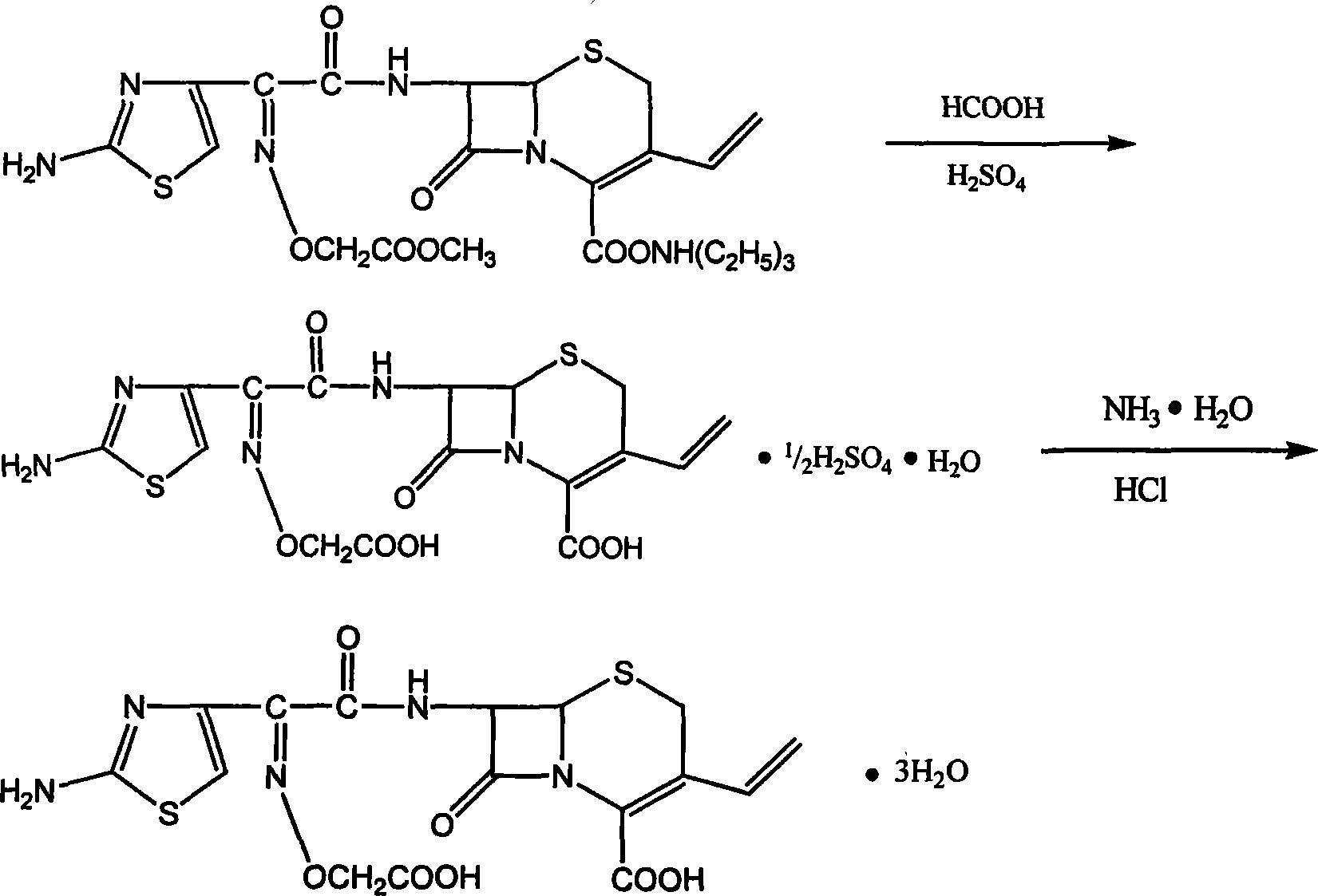

Method used

Image

Examples

Embodiment 1

[0020] In a 500ml dry three-necked flask, add 150ml of ethanol, lower the temperature to below 0°C, add 20g of cefixime methyl triethylamine salt under stirring, add 20ml of anhydrous formic acid, stir for 2 hours, and drop 98% of Sulfuric acid 8ml, stirred for 3 hours, filtered, washed with ethanol, and dried in vacuum at 50°C to obtain cefixime monohydrate monosulfate 13.6g. (Yield: 82%)

[0021] In a 1000ml three-necked flask, add 150ml of deionized water, lower the temperature to below 0°C, add 13.6g of cefixime monosulfate monohydrate under constant stirring, adjust the pH value to 5.5 with ammonia water, add 1g of activated carbon, decolorize and filter, and add 1g of activated carbon to the filtrate Add 100ml of ethanol, use 4mol / L hydrochloric acid to adjust the pH value to 4, raise the temperature to 25°C, then use 4mol / L hydrochloric acid to adjust the pH value to 2.5, stir for 30 minutes and then drop to below 0°C, stir for 2 hours, filter, Washed with ice water an...

Embodiment 2

[0023] In a 500ml dry three-necked flask, add 150ml of acetone, lower the temperature to below 0°C, add 20g of cefixime methyl triethylamine salt under stirring, add 20ml of anhydrous formic acid, stir for 2 hours, and drop 98% of Sulfuric acid 8ml was stirred for 3 hours, filtered, washed with acetone, and dried in vacuum at 50°C to obtain cefixime monohydrate monosulfate 13.1g. (Yield: 79%)

[0024] In a 1000ml three-neck flask, add 150ml of deionized water, lower the temperature to below 0°C, add 13.1g of cefixime monohydrate monosulfate under constant stirring, adjust the pH value to 7.5 with ammonia water, add 1g of activated carbon, decolorize and filter, and add to the filtrate Add 100ml of ethanol, use 4mol / L hydrochloric acid to adjust the pH value to 4, raise the temperature to 25°C, then use 4mol / L hydrochloric acid to adjust the pH value to 2.62, stir for 30 minutes, then drop to below 0°C, stir for 2 hours, filter, Washed with ice water and dried under vacuum at ...

Embodiment 3

[0026] In a 500ml dry three-necked flask, add 150ml of methanol, lower the temperature to below 0°C, add 20g of cefixime methyl triethylamine salt under stirring, add 20ml of anhydrous formic acid, stir for 2 hours, and drop 98% of Sulfuric acid 8ml, stirred for 3 hours, filtered, washed with methanol, and vacuum-dried at 50°C to obtain cefixime monohydrate monosulfate 12.8g. (Yield: 77.2%)

[0027] In a 1000ml three-neck flask, add 150ml of deionized water, lower the temperature to below 0°C, add 12.8g of cefixime monohydrate monosulfate under constant stirring, adjust the pH value to 5.9 with ammonia water, add 1g of activated carbon, decolorize and filter, and add to the filtrate Add 100ml of ethanol, use 4mol / L hydrochloric acid to adjust the pH value to 4, raise the temperature to 25°C, then use 4mol / L hydrochloric acid to adjust the pH value to 2.5, stir for 30 minutes and then drop to below 0°C, stir for 2 hours, filter, Washed with ice water and dried under vacuum at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com