Dust collection method with filtering liquid and device using the method

A dust removal device and liquid filtration technology, applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of frequent cleaning and secondary pollution, and achieve simple structure, low manufacturing cost, and convenient installation and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

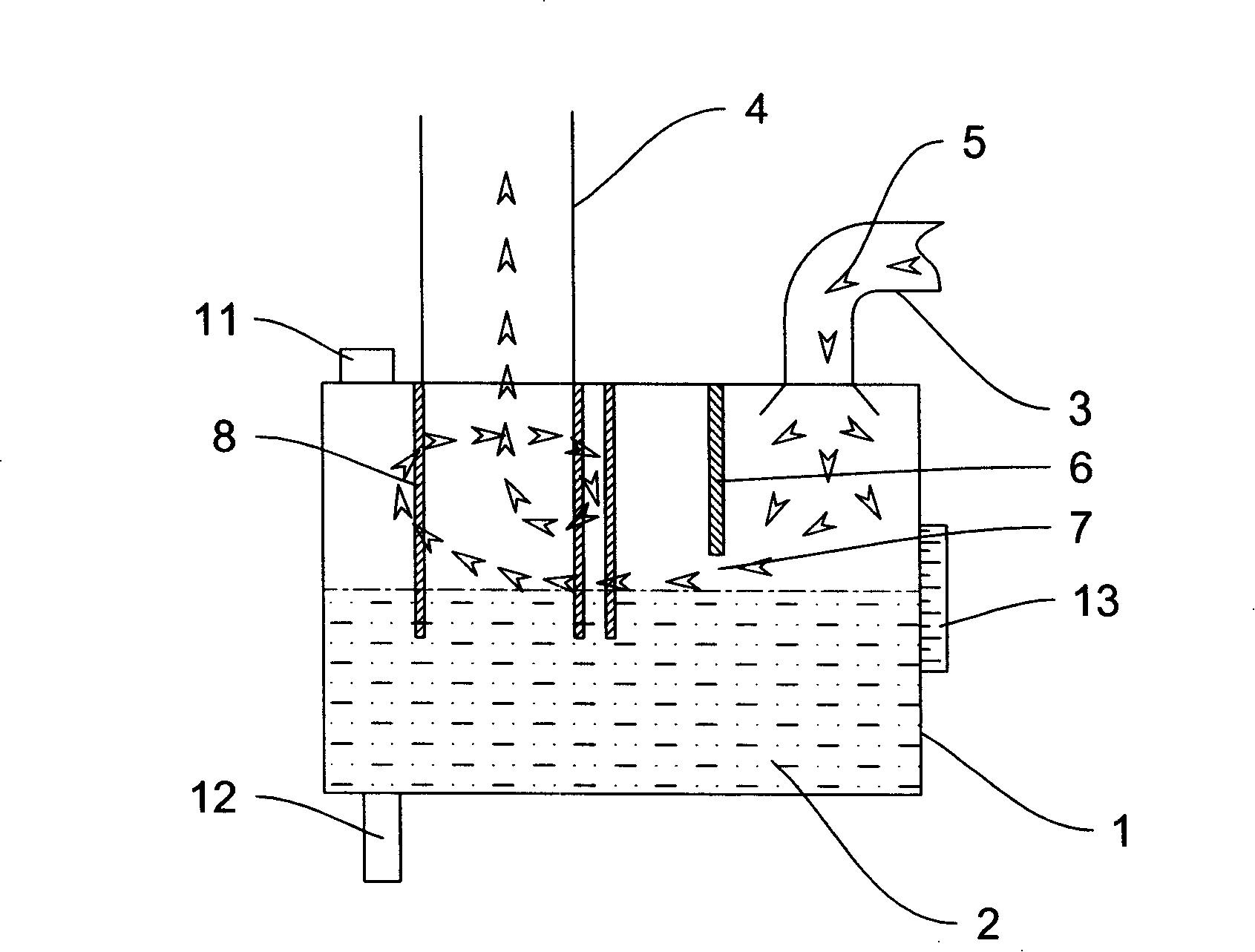

[0027] Such as figure 1 , 2 , 3, in the preferred embodiment of the liquid filter and dust removal device of the present invention, it includes a sealed liquid tank 1, which contains a liquid 2 of suitable depth. As mentioned above, the liquid 2 is preferably A liquid with a strong adsorption capacity for smoke and dust. The top of the liquid tank 1 is provided with an air inlet pipe 3 and an air outlet pipe 4, and the inside of the liquid tank 1 is also equipped with a slow wind device that can slow down the smoke 5 introduced from the air inlet pipe 3 and pass through it against the liquid surface. And the cyclone device that can make the flue gas 5 passing through the slow wind device rotate and then be discharged into the atmosphere by the air outlet pipe 4. A fan can be arranged at the outlet pipe 4 for drafting, so that the flue gas 5 can flow in the water tank. It is also possible to set the cross-sectional area of the air inlet pipe 3 to be smaller than the cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com