High voltage MOS device

A MOS device, high-voltage technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of slow speed, increase breakdown voltage, and small safe working area, so that the speed of the device is not affected, the breakdown voltage is improved, The effect of a large safe working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

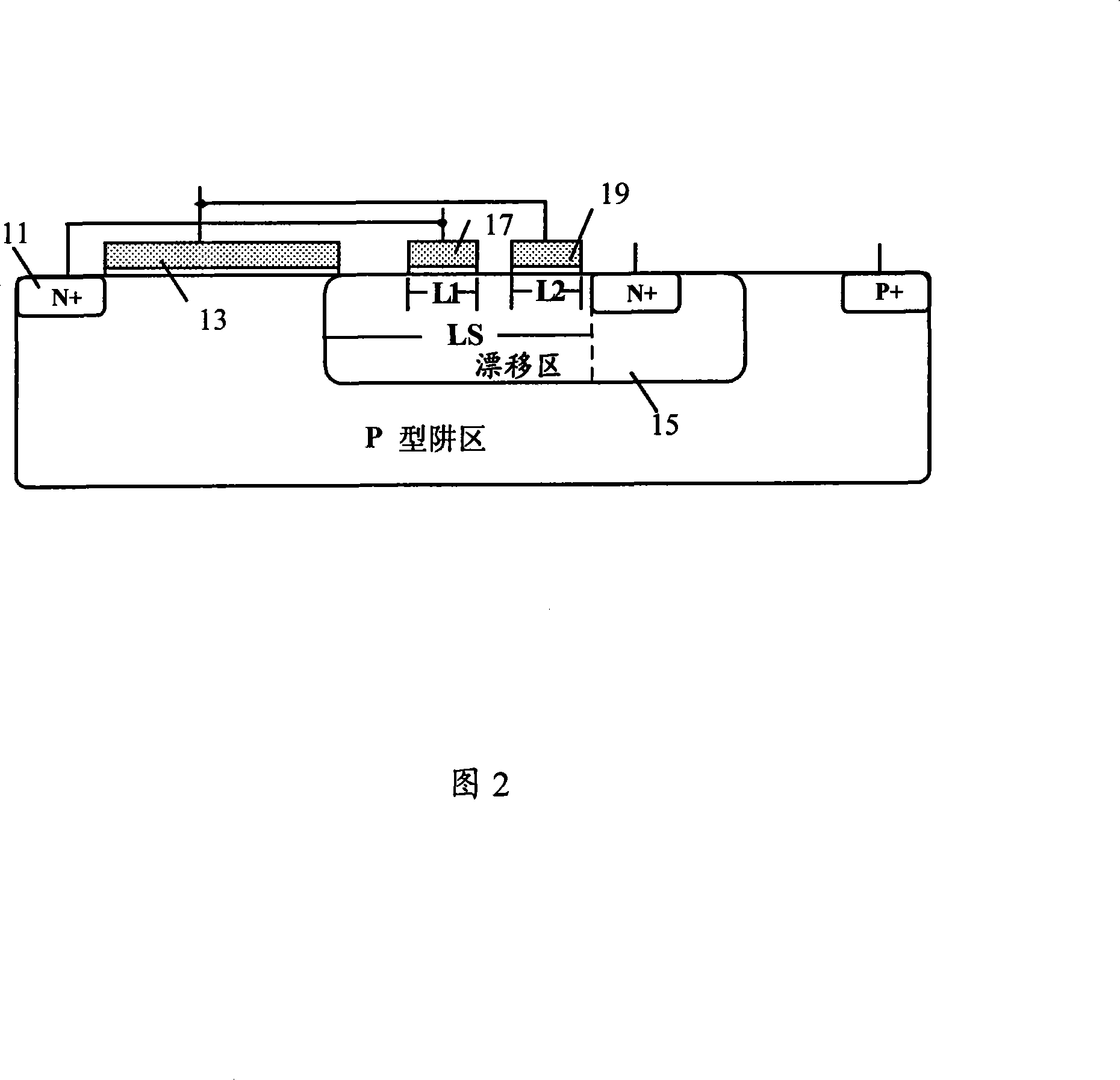

[0018] The present invention proposes a high-voltage MOS device, please refer to FIG. 2 , the device at least includes a source 11 , a gate 13 , a drift region 15 , a first field plate 17 and a second field plate 19 . Both the first field plate 17 and the second field plate 19 are made of a polysilicon layer with the same thickness as the polysilicon layer of the gate 13 , and are distributed on the upper surface of the drift region 15 at a distance from each other. Wherein, the first field plate 17 closest to the gate 13 is connected to the source 11 , and the second field plate 19 is connected to the gate 13 .

[0019] The lengths L1 and L2 of the two field plates 17 and 19 can be the same or different, and the lengths L1 and L2 range from the minimum value allowed by the process to about one-third of the length LS of the drift region 15, which can be determined according to different high-voltage MOS devices. Choose from different lengths ranging from 1 micron to 100 micron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com