Swirl type compressor and its control method

A compressor and scroll technology, which is applied in the field of scroll compressors and their control, can solve the problem of reduced reliability and performance of scroll compressors, reduced reliability of scroll compressors, and leakage of compression chambers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

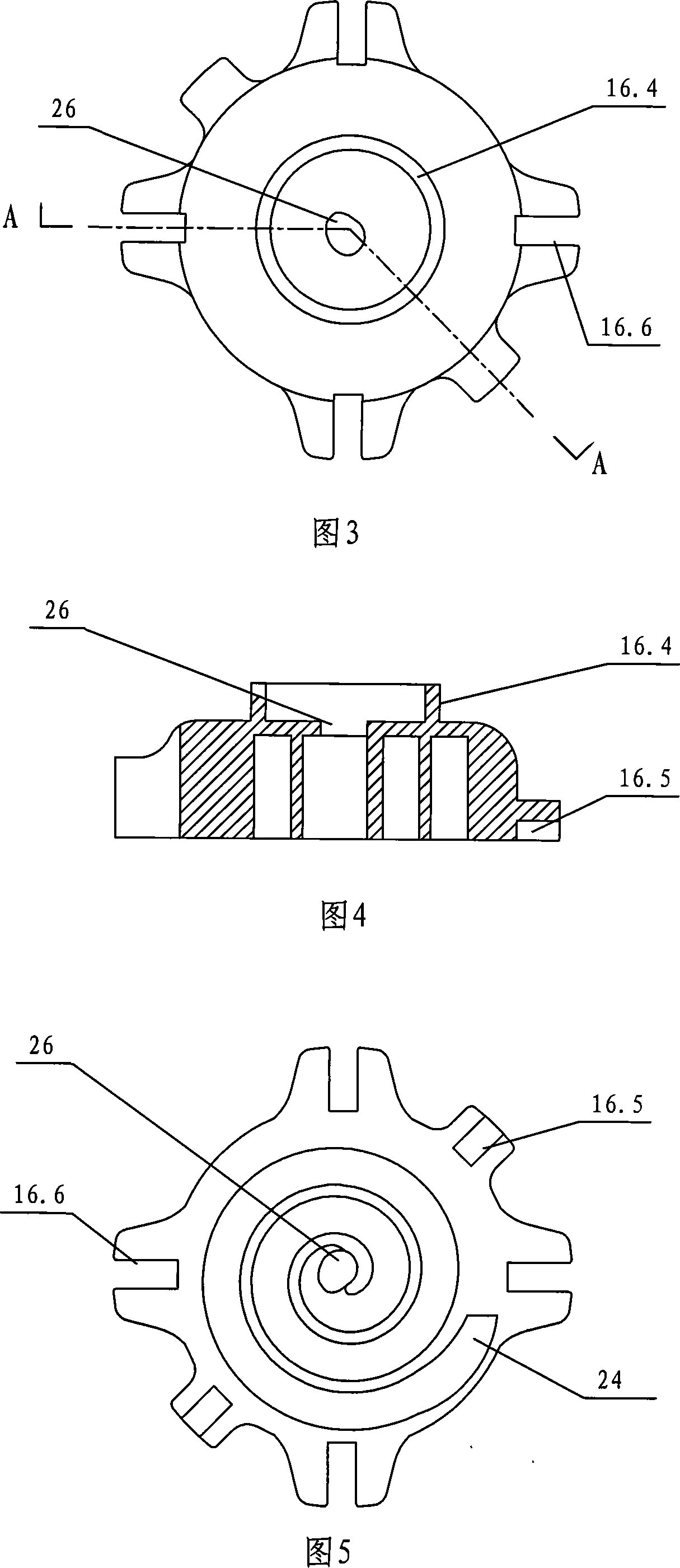

[0032]In the figure: 1 is the oiling through hole, 2 is the oiling blade, 3 is the oiling pipe, 4 is the lower bracket, 5 is the lower bearing assembly, 6 is the screw, 7 is the shell, 8 is the motor, 9 is the horizontal oil hole , 10 is the shaft, 11 is the frame, 11.1 is the supporting part, 11.2 is the assembly hole, 12 is the Oldham slip ring, 12.1 is the chute on the Oldham slip ring corresponding to the pair of keys of the rotating scroll, 12.2 is the chute with the static The key on the Oldham slip ring corresponding to the scroll chute, 13 is the rotating bearing, 14 is the oil supply hole of the compression chamber, 15 is the rotating scroll, 15.1 is the scroll, and 15.2 is the matching Oldham slip ring on the rotating scroll 15.3 is the protrusion on the back side of the orbiting scroll, 16 is the fixed scroll, 16.4 is the annular flange on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com