High-strength thick steel plate for large-scale petroleum storing tank and low-cost manufacturing method thereof

A technology of high-strength steel plates and oil storage tanks, which is applied in manufacturing tools, temperature control, furnace types, etc., can solve the problems of complex off-line quenching and tempering production process, poor performance stability of steel plates, and difficulty in ensuring delivery time, etc., to achieve good resistance Reheat Crack Sensitivity and Weldability, Improvement of Hardenability, Effect of Reducing Weld Crack Sensitivity Components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

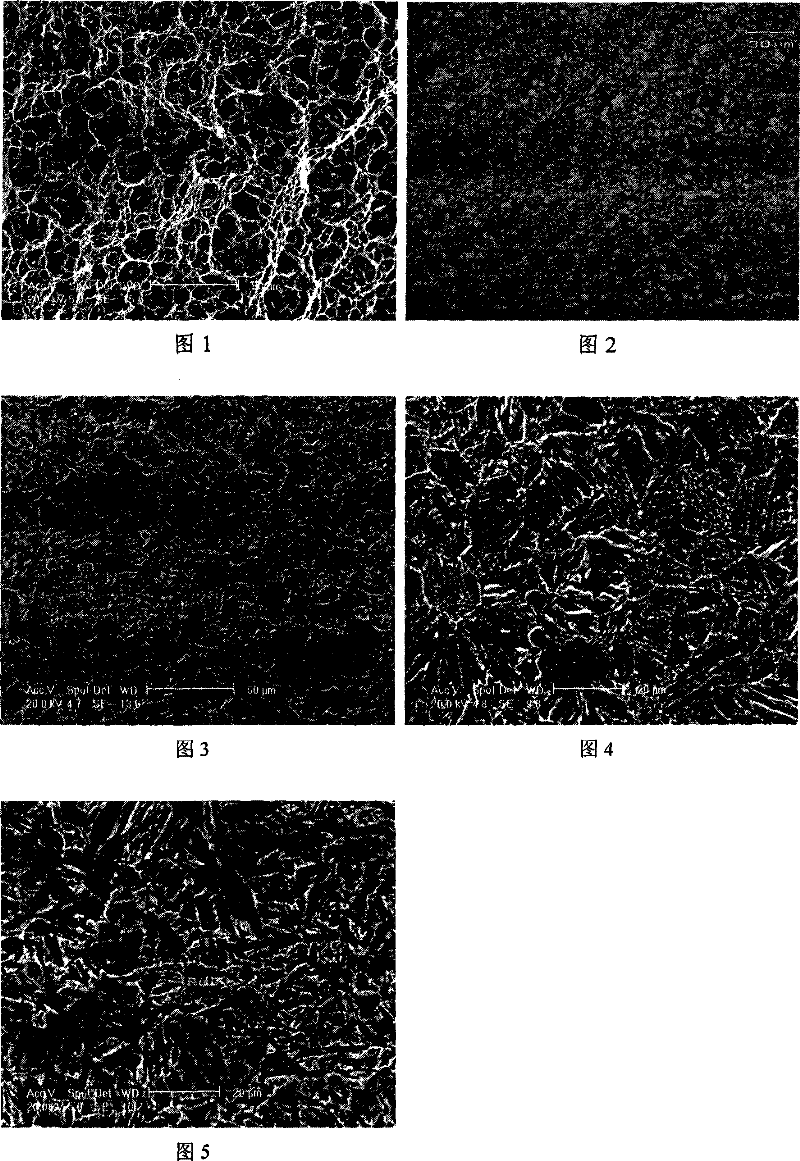

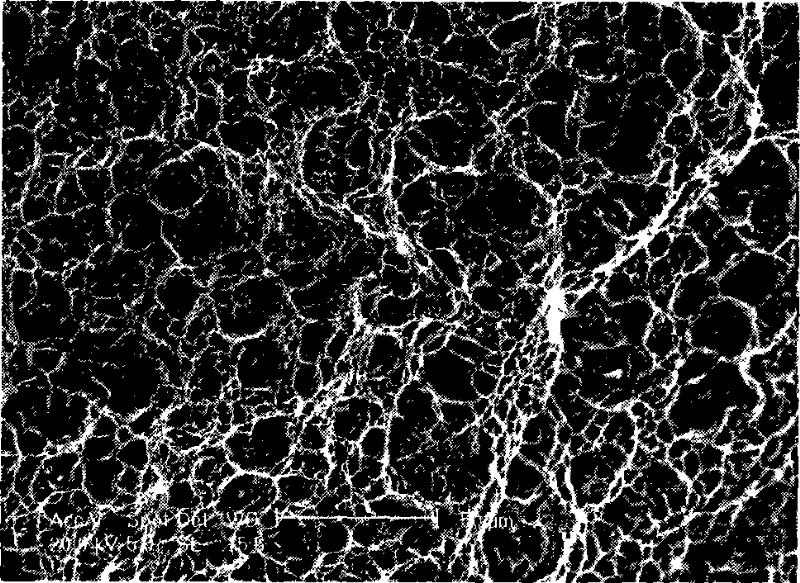

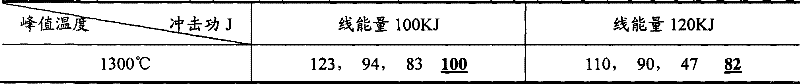

Image

Examples

Embodiment Construction

[0060] The steel of the present invention adopts an online quenching + tempering process to produce oil tank steel, and the process flow is as follows:

[0061] High-quality molten iron-KR hot metal pretreatment-120 tons top and bottom combined blowing converter-CAS station argon blowing treatment-LF furnace refining-VD vacuum degassing treatment-slab casting-walking heating furnace-high pressure water descaling-3200mm rolling mill rough Rolling-3500mm rolling mill finishing-online quenching-strong straightening-finishing-spray number marking-flaw detection-tempering-sampling inspection-storage-delivery.

[0062] Smelting process: using converter smelting, through top blowing or top-bottom combined blowing, for deep decarburization; using LF furnace and VD furnace vacuum treatment to reduce the content of harmful gases such as O, H, N and S; adding alloy elements to perform Microalloying; Ca treatment, feeding Si-Ca wire 1~6m / t, controlling the sulfide morphology, improving ductili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com