Red reactive dyestuffs and preparation method thereof

A technology of reactive dyes and red, applied in the field of red reactive dyes and its preparation, to achieve the effects of bright and beautiful shades, promotion of environmental protection, high exhaustion rate and color fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

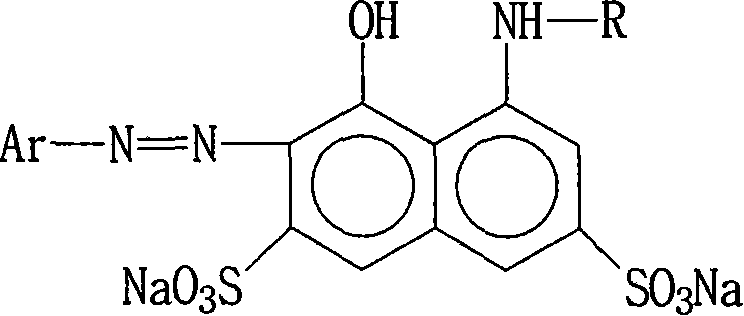

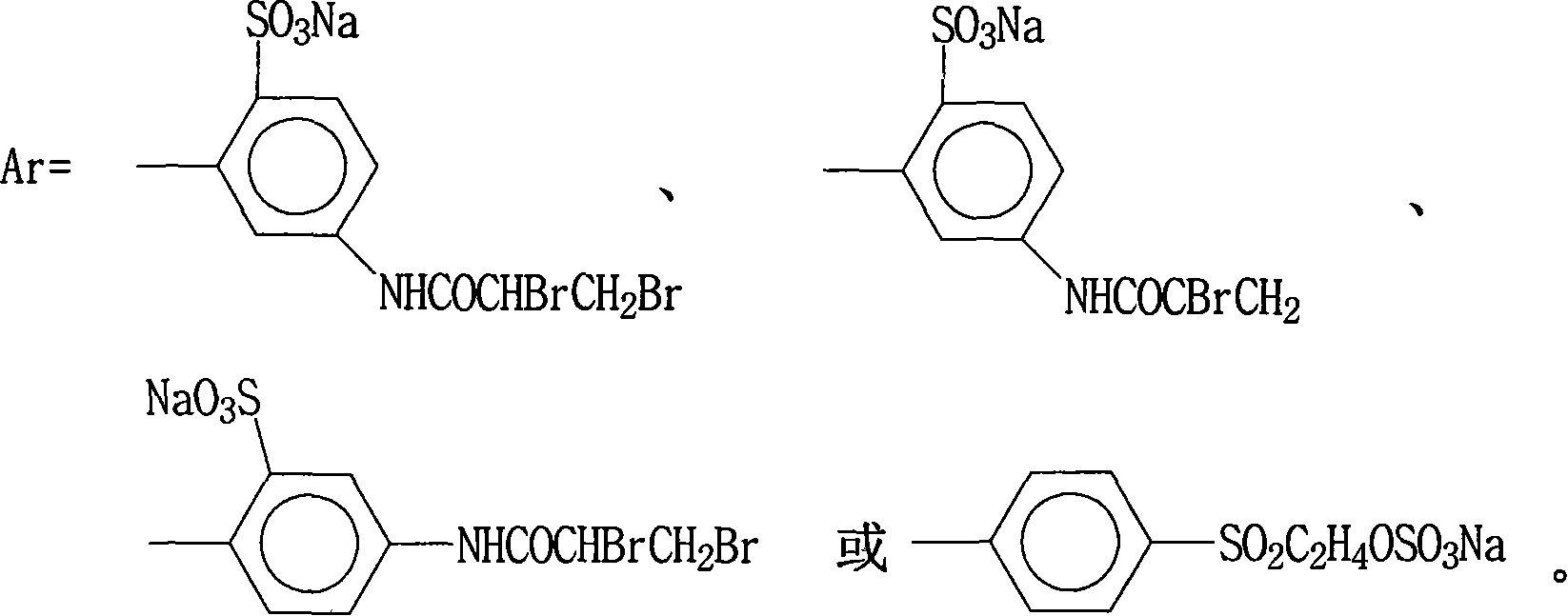

Method used

Image

Examples

preparation example Construction

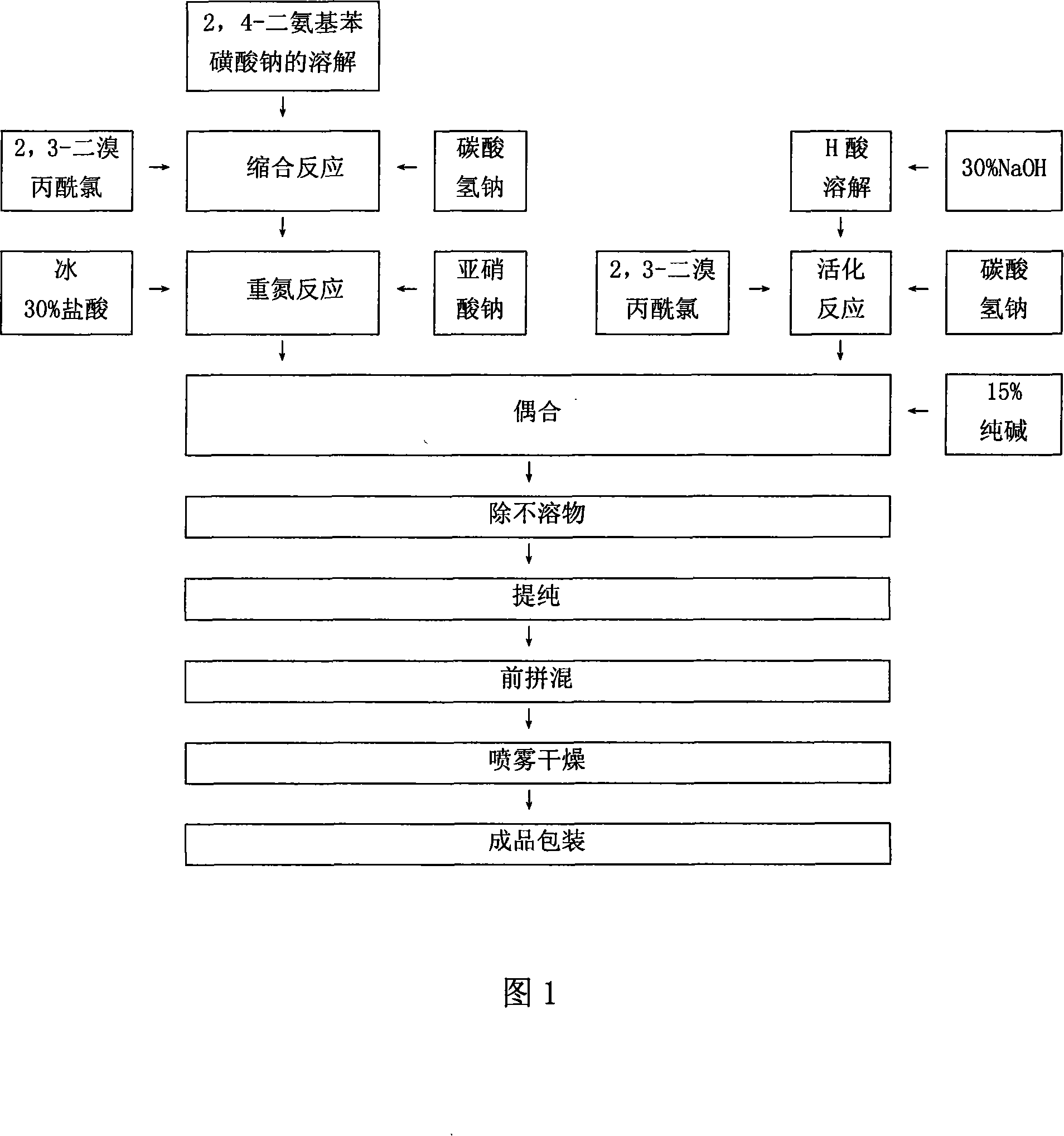

[0036] A preparation method for red reactive dyes, comprising the steps of:

[0037] a. 2.4-sodium diaminobenzenesulfonate is subjected to condensation reaction and diazotization reaction to prepare m-diactivator diazonium solution;

[0038] b. Activation reaction: add H acid in water, under stirring, add acid-binding agent, adjust pH=6.5-7, dissolve the material, clarify, the mass percentage concentration of the solution is 15-16%, directly add ice to cool down, adjust the volume, Make the mass percent concentration of the solution 10%, adjust the temperature to 5-7°C, add halopropionyl chloride dropwise, and react at pH=6-6.5;

[0039] c. Coupling reaction: use sulfamic acid to eliminate the excess nitrous acid in step a, then add the solution to step b along with the acid-binding agent, control the pH of the solution to 7, maintain the temperature at 15-20°C, and maintain the pH to 7 -7.5, the reaction time is 2.5-3 hours;

[0040] d. Remove insoluble matter: adjust the r...

Embodiment 1

[0050] 1. Ingredients list:

[0051] raw material name

[0052] 2, dyestuff preparation technology of the present invention operates as follows:

[0053] a. Dissolution of sodium 2,4-diaminobenzenesulfonate

[0054] Put 2400 liters of bottom water in the reaction tank, add 288.75 kg of sodium 2,4-diaminobenzenesulfonate, heat up to 22°C, stir and dissolve, so that the materials are completely dissolved and clarified. Adjust the pH to 6-6.5 with dilute hydrochloric acid. The volume is 2625 liters, and C%=11 in the solution (referring to mass percent concentration, the same below).

[0055] b. Condensation reaction

[0056]Use direct ice and jacketed circulating cold water to adjust the temperature of solution a to 0-5°C, adjust the C% in the solution to 10, add 2,3-dibromopropionyl chloride within 1.5-2 hours, and maintain it with sodium bicarbonate at the same time pH=6~6.5, stirred and reacted for 2 hours. The reaction temperature is 0-5°C, and the reaction pH...

Embodiment 2

[0086] a. Dissolution of sodium 2,4-diaminobenzenesulfonate

[0087] Put 2400 liters of bottom water in the reaction tank, add 288.75 kg of sodium 2,4-diaminobenzenesulfonate, heat up to 22°C, stir and dissolve, so that the materials are completely dissolved and clarified. Adjust the pH to 6-6.5 with dilute hydrochloric acid. The volume is 2625 liters, C%=11 in the solution.

[0088] b. Condensation reaction

[0089] Use direct ice and jacketed circulating cold water to adjust the temperature of solution a to 0-5°C, adjust the C% in the solution to 10, add 2,3-dibromopropionyl chloride within 1.5-2 hours, and maintain it with sodium bicarbonate at the same time pH=6~6.5, stirred and reacted for 2 hours. The reaction temperature is 0-5°C, and the reaction pH is 6-6.5. Finally, the end point was detected by TLC aluminum-based silica gel thin-layer plate.

[0090] c, diazotization reaction

[0091] Quantitative 30% hydrochloric acid solution was added to the condensation li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com