Battery electrolyte filling method

A battery and liquid injection technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problem of low liquid injection volume, and achieve the effects of high discharge capacity, improved cycle performance, and increased injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This example is used to prepare a battery without electrolyte.

[0022] (1) Preparation of positive electrode

[0023] 100 g of the positive active ingredient LiCoO 2 , 3 grams of polyvinylidene fluoride and 4 grams of conductive agent acetylene black were added to 50 grams of N-methyl-2-pyrrolidone, and then stirred in a mixer to form a uniform positive electrode slurry.

[0024] The slurry was evenly coated on aluminum foil, then dried at 150°C, rolled, and cut to obtain a positive electrode sheet with a size of 400×43.5 mm, which contained 5.8 grams of active ingredient LiCoO 2 .

[0025] (2) Preparation of negative electrode

[0026] 100 grams of graphite, 3.5 grams of polytetrafluoroethylene, 0.5 grams of sodium carboxymethylcellulose, and 4 grams of conductive agent acetylene black were added to 120 grams of water, and then stirred in a mixer to form a uniform negative electrode slurry.

[0027] The slurry is evenly coated on the copper foil, then dried at 90°...

Embodiment 2

[0031] This example illustrates the injection method of the electrolyte solution of the battery provided by the present invention.

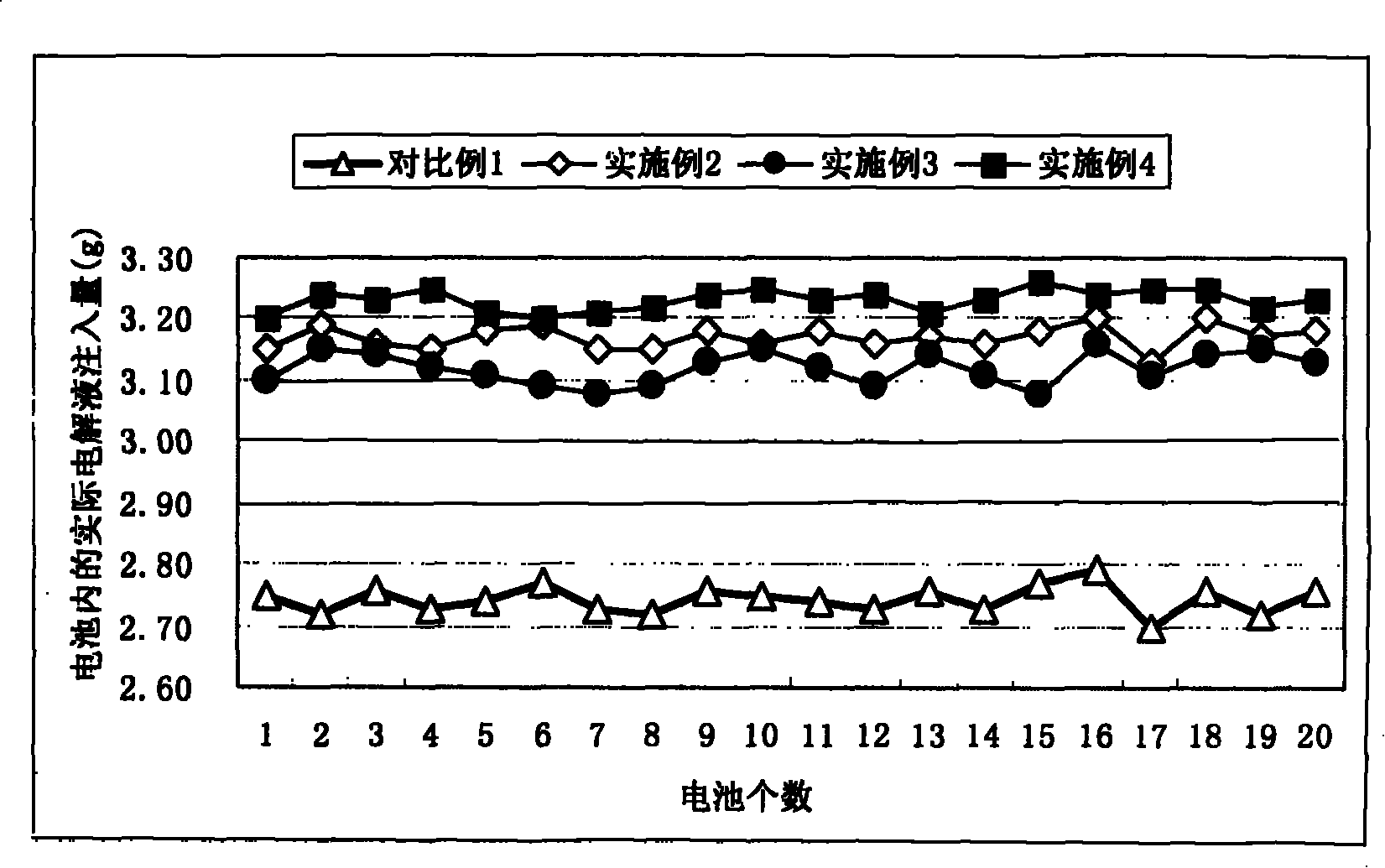

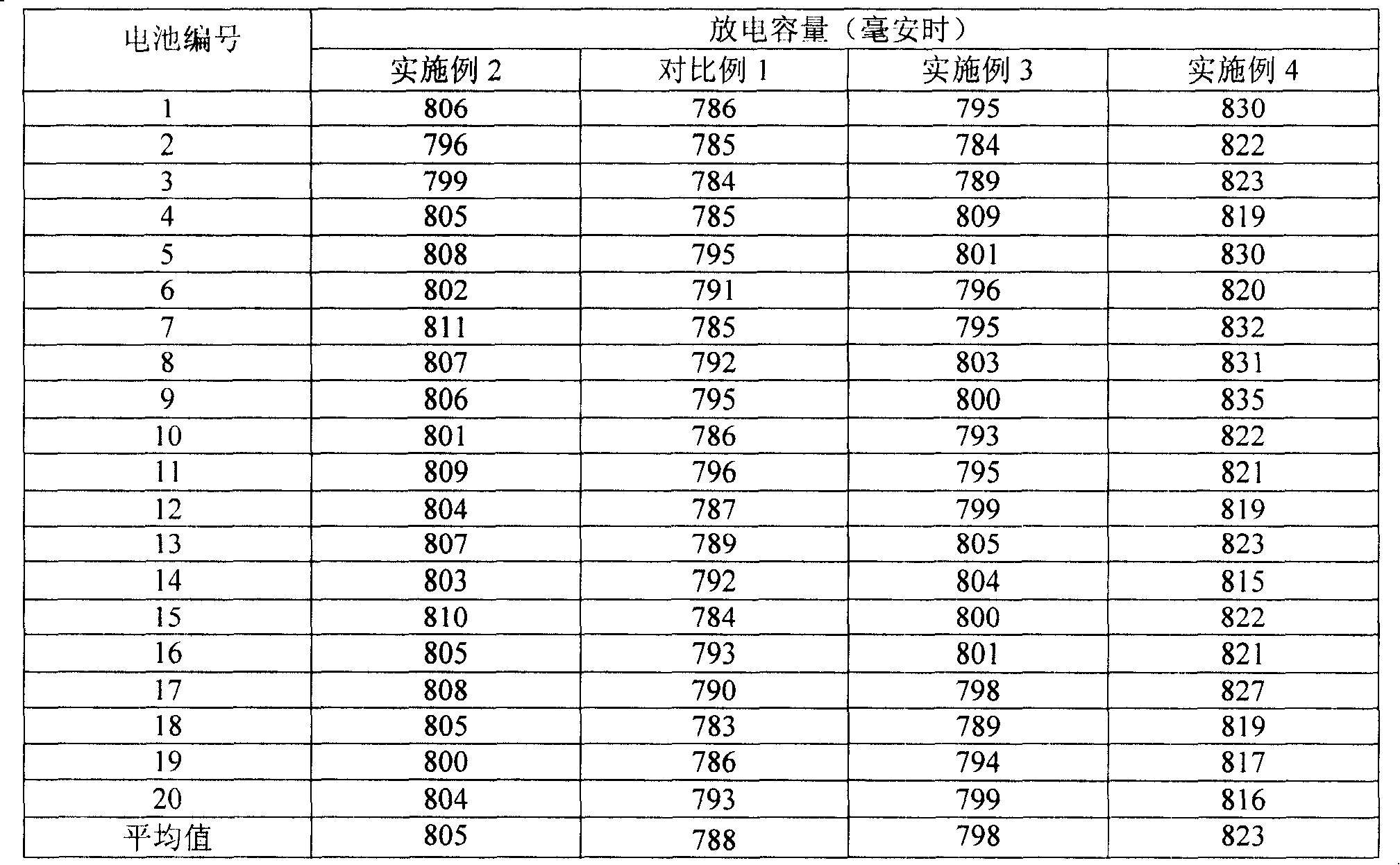

[0032] The electrolyte lithium salt LiPF 6 It is dissolved in a non-aqueous solvent at a concentration of 1 mole / liter to form a non-aqueous electrolyte, and the non-aqueous solvent is a mixed solvent of ethylene carbonate and dimethyl carbonate with a volume ratio of 1:1. Use a vacuum liquid injection machine (produced by Guangzhou Lange Electric Equipment Co., Ltd., model LDZ-20) to the battery W without electrolyte obtained in Example 1 (the battery W was weighed before the liquid injection, and the weight was 14.65 grams. ) for vacuum liquid injection, first use the vacuum liquid injection machine to evacuate the battery until the pressure in the battery case is 500-1000 Pa, then inject 3.0 grams of the above-mentioned electrolyte solution, and wipe off the leaked electrolyte solution. The battery was weighed, and the weight was 17.25 grams,...

Embodiment 3

[0038] This example illustrates the injection method of the electrolyte solution of the battery provided by the present invention.

[0039] The electrolyte lithium salt LiPF 6 It is dissolved in a non-aqueous solvent at a concentration of 1 mole / liter to form a non-aqueous electrolyte, and the non-aqueous solvent is a mixed solvent of ethylene carbonate and dimethyl carbonate with a volume ratio of 1:1. Use a vacuum liquid injection machine to carry out vacuum liquid injection to the battery W without electrolyte obtained in Example 1 (the battery W is weighed before the liquid injection, and the weight is 14.64 grams). The battery is evacuated until the pressure inside the battery shell is 10-500 Pa, and then 2.3 grams of the electrolyte prepared above is injected into the battery without leakage. The battery is weighed, and the weight is 16.94 grams, and sealed with adhesive tape. The battery was then placed in a centrifuge and centrifuged at a speed of 1500 rpm for 8 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com