Packaging material composition

A technology for packaging materials and compositions, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of expensive materials, insufficient protection of LED devices, and high volatility of antioxidants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Formula Table:

[0043]

[0044]

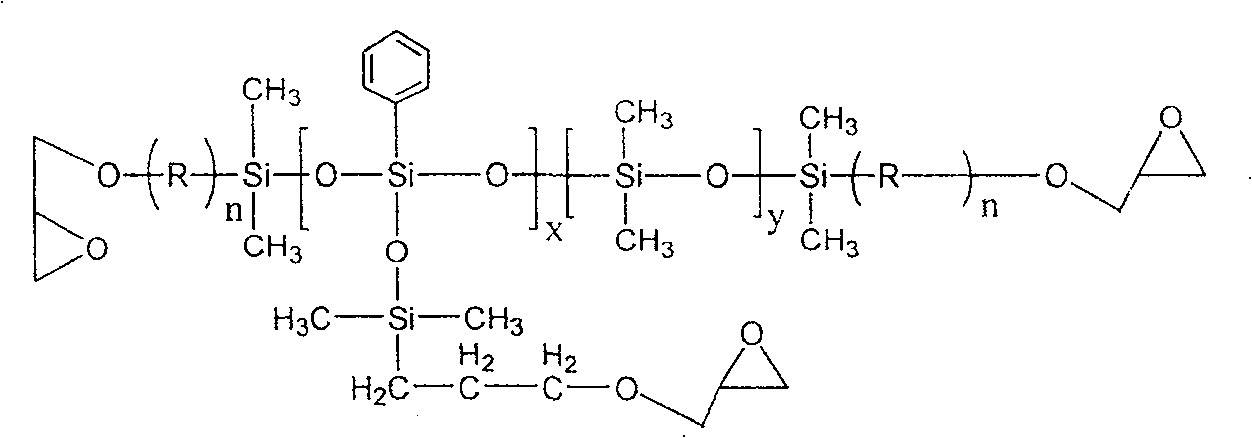

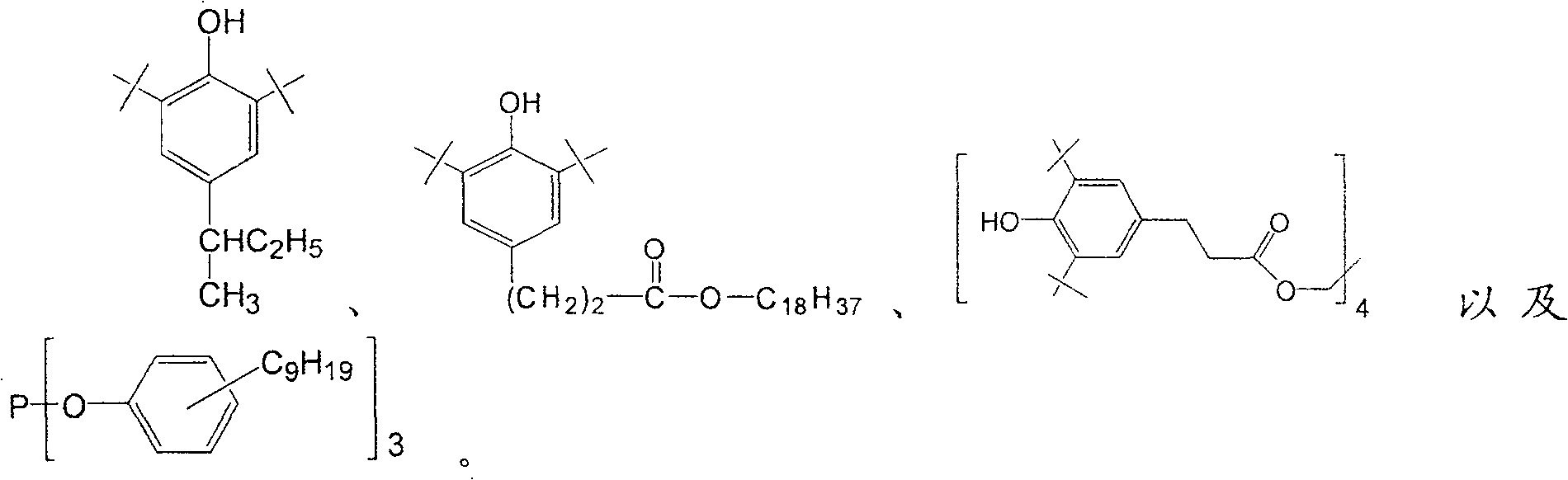

[0045] Wherein the epoxy resin of non-siloxane is bisphenol A diglycidyl ether (Diglycidyl ether of Bisphenol A) (EPON-828, purchased from Shell chemical company), and the siloxane epoxy resin is (phenylmethylsiloxane) alkane-co-dimethylsiloxane)-triglyceryl ether terminated resin (Phenylmethylsiloxna e-co-dimethylsiloxne)-triglycidyl ether terminated) (GT-1000, purchased from Guangke Chemical Company), the anhydride hardener is formazan Methylhexahydrophthalic anhydride (MHHPA), catalyst is quaternary Quaternary phosphonium bromide (U-cat 5003, purchased from San-apro limited. company).

[0046] Put the catalyst (U-cat 5003) and hardener (MHHPA) in the formula table into the reactor, stir at room temperature for 1 hour; after the catalyst is dissolved, add epoxy resin (EPON-828>-1000) to the reaction In the container, stir at room temperature for 1 to 2 hours; then vacuum degas the uniformly mixed resin material for half an h...

Embodiment 2

[0049] Formula Table:

[0050]

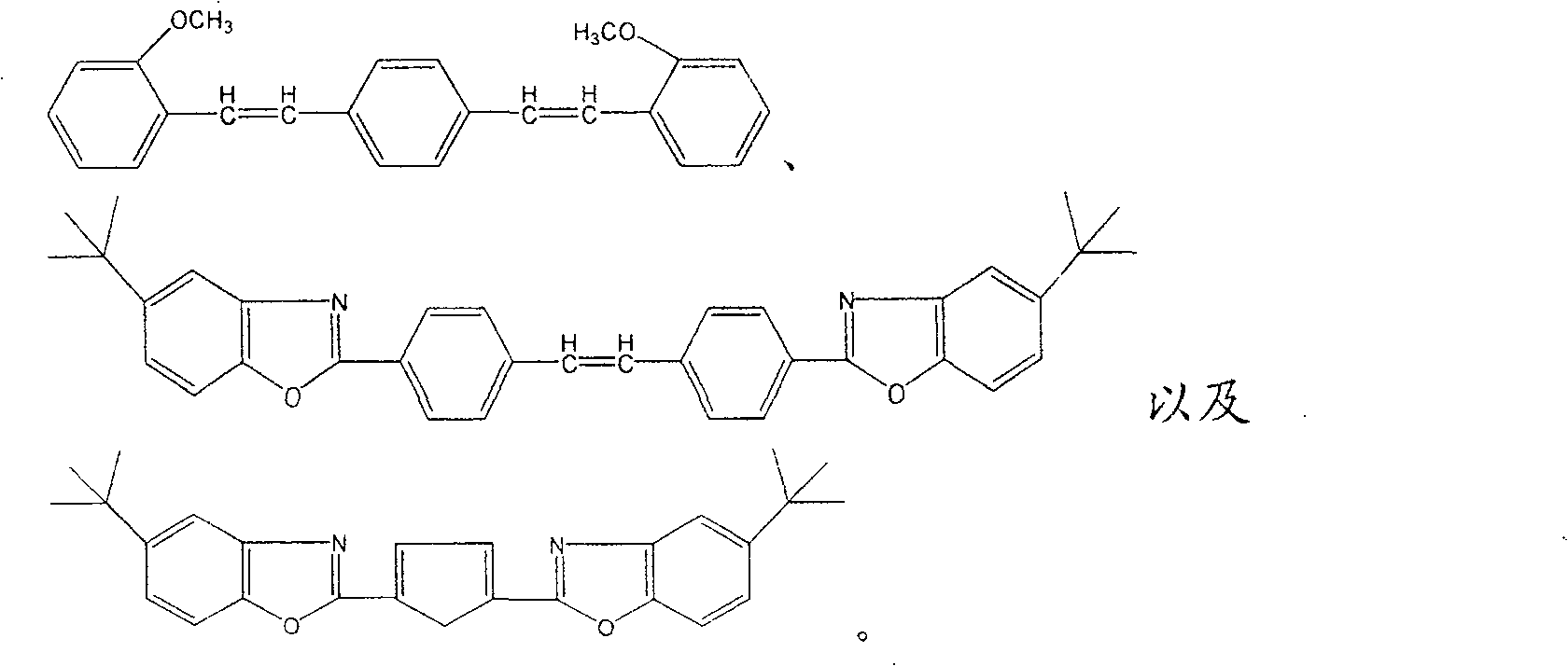

[0051] The preparation method of the encapsulation material of embodiment 2 is the same as embodiment 1, and its difference is to add fluorescent whitening agent Chitex 127 (purchased from Double bond chemical company) in its formula, molecular structural formula is as follows:

[0052]

[0053] It is placed in a reactor together with the catalyst and the hardener, and after stirring for 1 hour at normal temperature, the subsequent steps are carried out.

[0054] The encapsulation material sample prepared in Example 2 was measured in the same manner as in Example 1, and the obtained yellowing coefficient changes are listed in Table 1.

Embodiment 3

[0056] Formula Table:

[0057]

[0058] The manufacturing method of the encapsulation material of embodiment 3 is the same as embodiment 2, and its difference is that the epoxy resin of non-siloxane used in its formula is cycloaliphatic epoxy resin (Cycloaliphatic epoxy) (4221EL, purchased from Dow chemical. company), and the siloxane epoxy resin it uses is also different from Example 2, which is GT-1250 (purchased from Guangke Chemical Company), which has the same chemical structure as GT-1000, but the difference is that its average ring The oxygen equivalent weight is 1150-1650g / equivalent.

[0059] The encapsulation material sample prepared in Example 3 was measured in the same manner as in Example 1, and the obtained yellowing coefficient changes are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com