Method for manufacturing rice-shaped precipitated calcium carbonate

A technology of precipitated calcium carbonate and manufacturing method, applied in the direction of calcium carbonate/strontium/barium, inorganic compound addition, pigmented coating, etc., can solve the problems of alkali discharge treatment and recovery, high cost of precipitated calcium carbonate, etc., to maintain printing quality, The effect of tight arrangement and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

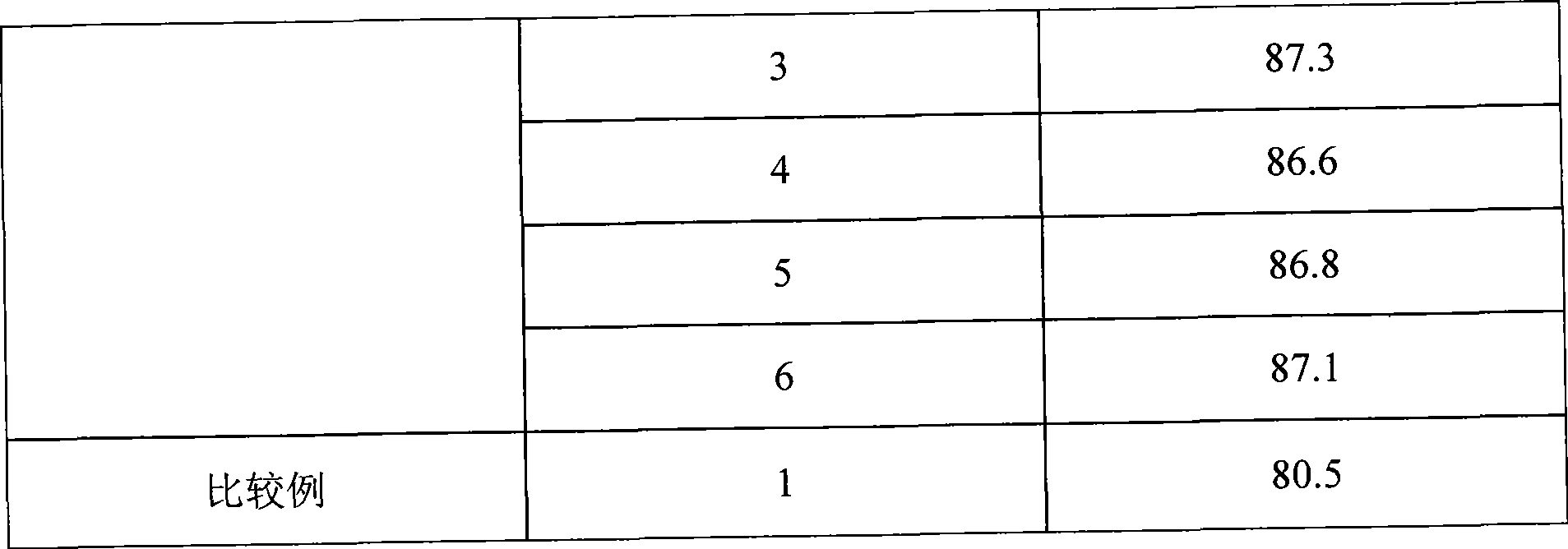

Embodiment 1

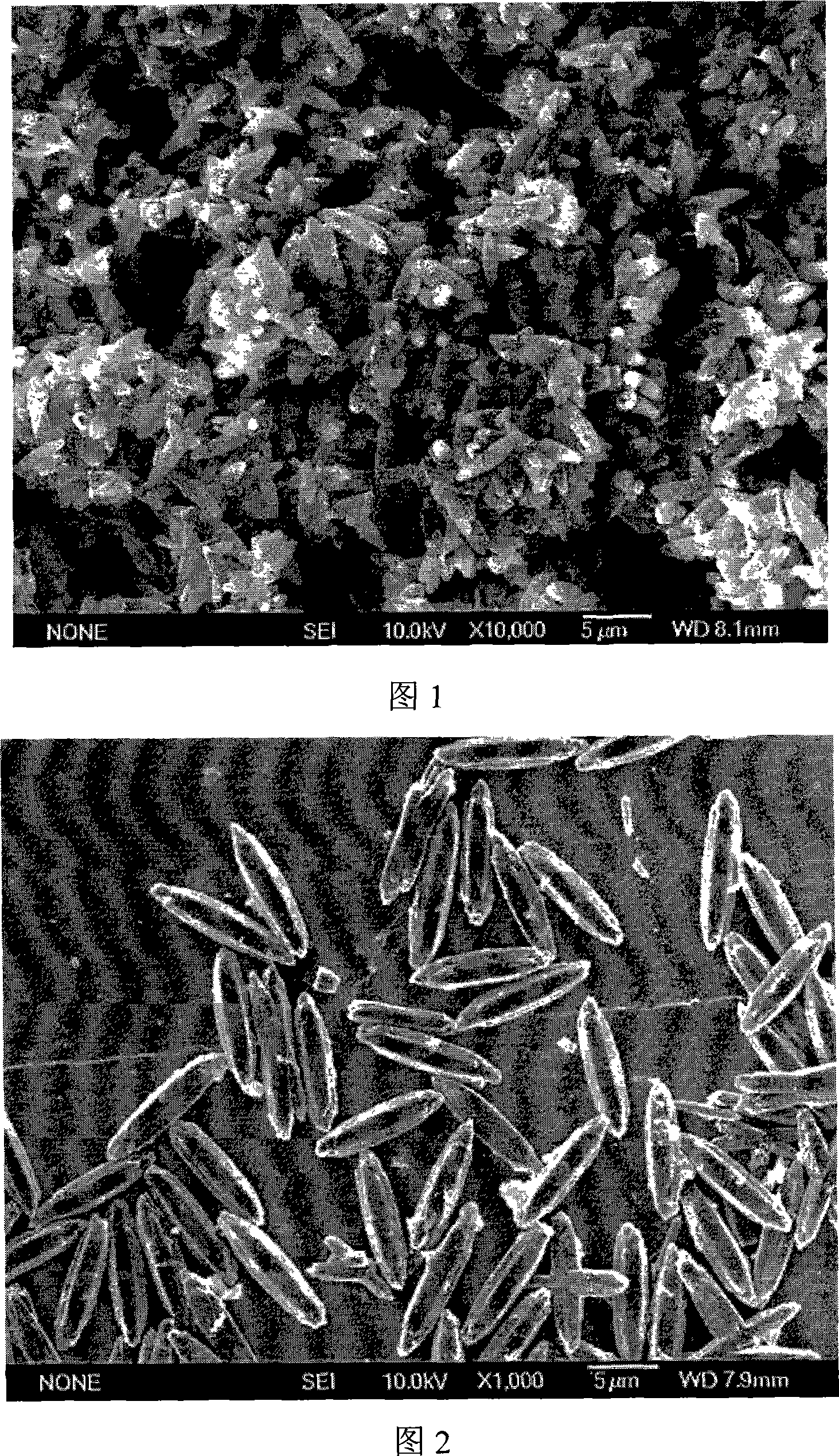

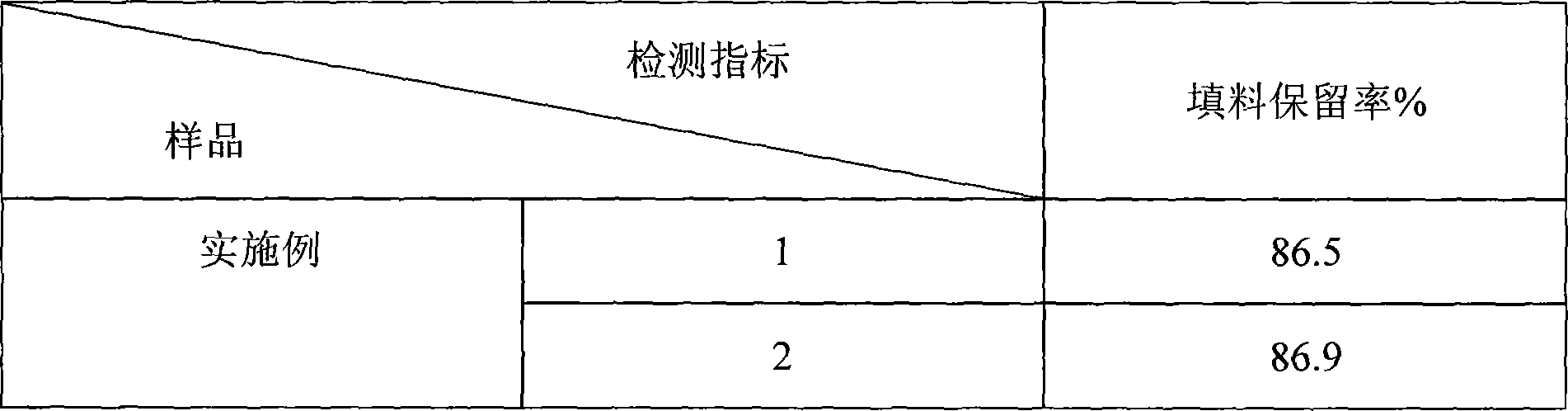

[0019] In a 2500ml beaker, add 1600g of lime emulsion with a concentration of 10wt%, then continue to add 1.6g of 1% sodium carbonate, stir and mix, then heat up to 15°C to start carbonization, with a stirring speed of 200rpm, react until the pH of the solution reaches 7.5, and then filter to obtain Cake 520g, measured average particle size 3.2 μm after drying (JL-1155 type laser particle size distribution tester of Chengdu Jingxin Powder Testing Equipment Co., Ltd.), crystal shape is rice grain shape (JSM-5300 scanning electron microscope observation of Japan Electronics Corporation) (see Figure 1).

Embodiment 2

[0021] In a 2500ml beaker, add 1600g of lime emulsion with a concentration of 20wt%, then continue to add 9.6g of 3% sodium bicarbonate, stir and mix, then heat up to 50°C to start carbonization, with a stirring speed of 200rpm, react until the pH of the solution reaches 6.5, and then filter to obtain The filter cake is 680g, and the average particle diameter after drying is 4.8 μm, and the crystal shape is rice grain.

Embodiment 3

[0023] In a 2500ml beaker, add 1600g of lime emulsion with a concentration of 30wt%, then continue to add 24g of 5% potassium carbonate, stir and mix and heat up to 60°C to start carbonization at a stirring speed of 200rpm, react until the pH of the solution reaches 8.0, and then filter to obtain 810g of filter cake After drying, the average particle size is 5.5 μm, and the crystal shape is rice grain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com