Detonator type nonpriming material detonator and non-electric detonating system thereof

A non-priming charge, detonating tube type technology, applied in fuze, blasting, blasting tube and other directions, can solve the problems of high cost, complicated assembly process, unsafe electric detonating detonator tube charge, etc., to avoid false explosion and assembly. complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

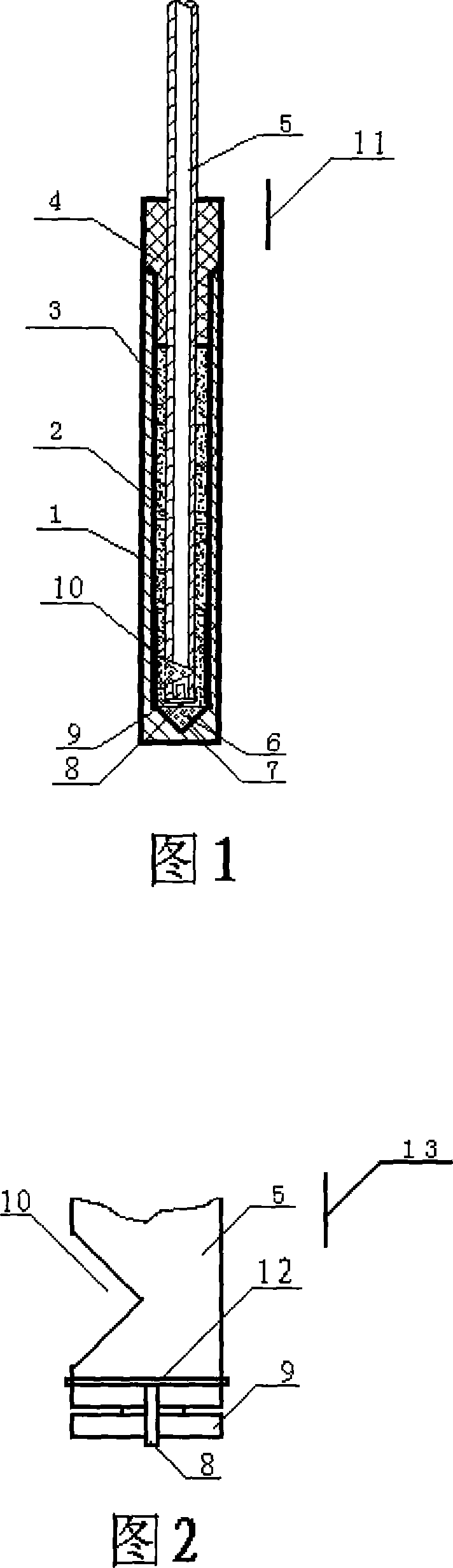

[0038] A detonator 11 with iron shell 1 of Ф10mm and length of 80mm manufactured according to the structure of Fig. 1 without priming charge is used in the energy gathering hole 7 at the bottom: 7.2 parts of aluminum powder, 72.8 parts of high explosive and 20 parts of black powder, the mixing density is 1.2g / cm 3 of mixed explosive pads are compacted flat. A plastic detonating tube 5 with an average length of 1.5m is used, and a flared opening 10 is set on one side of one end, the T-shaped plug 9 is replaced by a tack, the longitudinal elastic member 8 is an elastic rubber strip, and the horizontal fixing member is used. 12 Use general ropes. Plug the tack on the hole at the end of the detonating tube 5, and use an elastic rubber strip to tightly hoop the middle of the outside. The said check valve 13. Insert the plastic detonating tube 5 with the end of the check valve 13 into the tube shell 1 that has been cushioned with mixed explosives in the energy gathering hole 7, a...

Embodiment 2

[0040] The non-priming charge detonator manufactured by the structure of Fig. 1, as the detonator made in Example 1, wherein the composition weight ratio of the mixed explosive is: 5~15 parts of aluminum powder, 65~80 parts of high explosive and 15~15 parts of black powder 25 parts, the density is 0.7~1.2g / cm 3 . If a mixed powder ratio is: 7.2 parts of aluminum powder, 72.8 parts of dynamite and 20 parts of black powder, the mixed density is 0.9g / cm 3 The other mixing ratio is: 7.7 parts of aluminum powder, 77.3 parts of high explosive and 15 parts of black powder, and the mixing density is 1g / cm 3 When using a fire detonator to detonate two detonators at the same time, both detonators can be detonated, but there are differences in the sound and light source of the detonation of the two detonators.

Embodiment 3

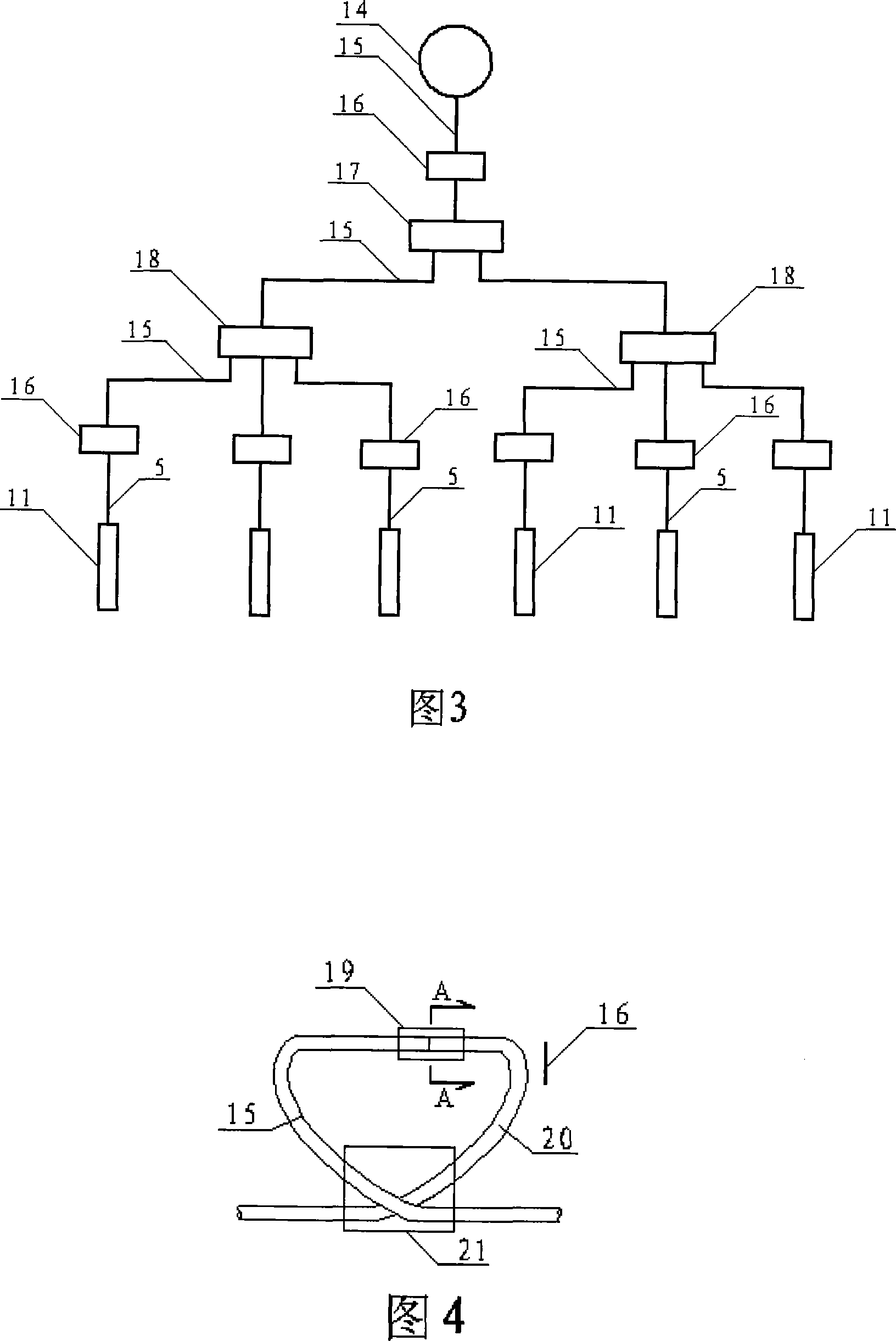

[0042] A non-electric type detonation system without primer detonator formed according to Figure 3, its firing device 14 is a fire detonator, and the detonating element is a plastic detonator 15 and one-to-one joints 16, one-to-two joints 17 and One is connected to the three-joint 18 branch connection structure, and the working end element is made of a plastic detonator type non-priming charge detonator 11 or a fuse (which replaces the fuse type non-priming charge detonator) and other non-electric type non-priming charge detonators. After connection and detonation, all non-electric detonators without detonators are detonated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com