A detonator laser coding line

A coding line and laser technology, used in detonators, offensive equipment, etc., to achieve the effect of improving coding speed, ensuring coding quality, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

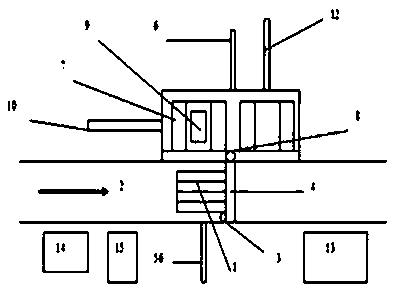

[0015] Further illustrate the present invention below in conjunction with accompanying drawing.

[0016] The invention is a detonator laser coding line, which is characterized in that it includes a coding mold 1, an antistatic belt 2, a bar 4, an upper mold photoelectric tube 3, an upper mold cylinder 5, a positioning cylinder 6, a safety door cylinder 8, and a laser coding head 9. Horizontal pushing magnetic cylinder 10, lower mold photoelectric tube 11, lower mold cylinder 12, laser control cabinet 13, industrial control box 14, air source 15; the laser control cabinet 13 includes the main control box, laser power supply box, laser head, computer , Safety protection box; Industrial control box includes PLC programmer, switching power supply, and protection circuit.

[0017] Further, hollow out under the coding workbench 7, when a detonator explodes accidentally, the energy can be released from the hollowed out bottom, while the upper part of the coding workbench 7 is designe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com